-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

June 21, 2023

What is Design for Excellence (DfX)?

Engineers often talk about the importance of design for excellence (DfX) and the impact it has on a product’s overall time to market, field reliability, and customer satisfaction. DfX can have a significant impact on the success of a business and a design, and it’s worthwhile to know its methodologies and how they can be implemented. Let’s take a look at DfX fundamentals and how companies can employ it to their best advantage.

Design for excellence is a systematic and proactive approach to design that uses the knowledge and experience of experts in other parts of the product development process (e.g., test, manufacturing, operations, and support) to ensure the final product can be realized at reasonably low life cycle cost while still meeting reliability, quality, durability, and customer expectation targets.

Design for excellence is based on the premise that getting product design right the first time is far less expensive than finding failure later in product development or at the customer level. By assessing issues beyond the base functionality of the product early in the design phase, practitioners of a robust DfX approach achieve significant reductions in defects, scrap, rework, retest, and increases in product yield.

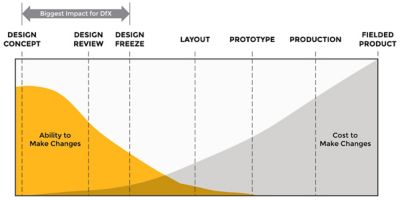

Implementing DfX early in the design phase ensures changes can be made quickly before prototype, saving time and costs.

Benefits of DfX

Product differentiation: As electronic technologies reach maturity, there are fewer opportunities to set products apart from the competition through traditional metrics like price and performance. DfX approaches allow companies to keep production and support costs low while achieving impressive reliability and durability that delights their customers.

Reliability assurance: Advanced circuitry, sophisticated power requirements, new components, new material technologies, and less robust parts make ensuring reliability increasingly difficult. Implementing a DfX approach that includes well-thought-out design for reliability (DfR), design for use environment (DfE), and design for test (DfT) programs significantly lowers the cost of ensuring reliability and reduces the risk of unexpected failures in test or in the field.

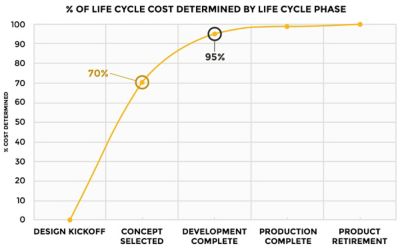

Cost control: Although it varies by product, typically about 70% of a new product introduction project’s cost is determined by the design concept selected. By the time the design process is complete, up to 95% of product life cycle cost is locked in. Design changes after that point are costly and have negative impacts on preproduction program cost and product release timelines.

By using a DfX approach, companies can apply expertise and lessons learned from manufacturing, assembly, testing, packaging, maintenance and repair, actual use environments, and other areas unrelated to design to minimize design, manufacturing, and support costs.

Seventy percent of a new product introduction (NPI) is determined by the design concept selected. By the time the design process is complete, 95% of product development costs are locked in.

Accelerating time to market: Especially in highly competitive markets, getting to market quickly with a product customers want and need is critical to starting ahead of the competition and capturing market share. Getting to market quickly and being recognized as offering one of the best products on the market can be a difficult balance that is made easier through an effective DfX strategy.

Redesign, test failures, and assembly and manufacturing problems all rob valuable time from the new product introduction schedule. DfX approaches bring a concurrent engineering philosophy to design that considers the needs of every product development stage in order to create a design that will flow through prerelease phases with minimal design-related roadblocks.

When is DfX Used?

DfX principles can be applied at any time in the product life cycle where design happens, including initial design and redesign. Of course, for any new product introduction (NPI), DfX practices should be implemented as early in the design phase as possible. For a fielded product or a product that is already well into other phases of product development, it’s never too late to consider DfX approaches when the need to redesign comes along.

New product introduction: Due to perceived cost or fears of stifling creativity and innovation, there may be some resistance to implementing DfX in the early concept phase of a design, but it is critical to bring in DfX specialists and lessons learned as early as possible to maximize the benefits. Even in the concept phase, it is important to ask questions like:

- What impact will the design have on reliability?

- Will a new technology need to be invented to make this design a reality?

- What manufacturing challenges does this design pose?

- How will the fielded product be supported?

Although these considerations are far down the line from concept design, they can be crucial to design concept trade-offs and getting the design phase kicked off in the right direction. At the very least, the DfX program should be in full effect before detailed design requirements are established.

Product mid-development: If a product is largely past the design phase but experiences problems in preproduction, test, or manufacturing that require a redesign to address, DfX practices can help ensure that the next redesign will be the last. Applying DfX expertise at this stage helps identify the true root causes driving the redesign and results in a design more suited to being tested, manufactured, assembled, deployed, repaired, etc.

Fielded product: Fielded products that go through redesign as part of a proactive product improvement program or to address field reliability, performance, maintainability, or safety concerns can also benefit from DfX practices. Identifying root causes of any issues and developing the requirements for the redesign are key tasks in which the DfX methodology can have the most impact to minimize the cost and timeline for the redesign effort.

Who Should Be Involved with DfX?

While DfX approaches require the knowledge of experts, successful design teams ensure that everyone on the team understands, implements, and sees the value of the DfX methodology. Successful DfX teams capture and use expert knowledge in the form of design requirements, design rules, and team member training to ensure that everyone on the team is using DfX best practices. For experts to help address novel problems, they should be included at critical design milestones to help identify risk and develop mitigation strategies.

Depending on the size and structure of the organization, job titles may vary, but key participants in the DfX program should have expertise in component selection and sourcing, reliability physics, assembly and manufacturing, test, field support practices and logistics, and use environments and stressors. Depending on the product and its intended use, expertise in areas such as thermal management, applicable environmental regulations, safety, reuse and recycling, and cost management may also be helpful.

DfX Best Practices

Start early. Implementing DfX practices early in the design process produces higher quality products at lower life cycle cost, with shorter times to market. The longer you wait, the less impact DfX will have on the final product.

DfX helps prevent problems early in design, rather than problem solving and redesigning later in the product development process.

People, processes, and tools. Starting from scratch is not easy. A solid DfX program requires:

- People with the right expertise, training, and a continuous improvement mindset.

- Well-documented, easily accessible, and standardized processes that incorporate best practices and lessons learned.

- Standard tools that make implementation of expert knowledge easy for everyone on the design team. In fact, a well-designed DfX program should mean fewer tools in your design process rather than more.

Use only what you need. Depending on who you ask, there are nearly 50 different DfX practices. The good news: You typically only need a few to make a positive impact on your product development process. Design for reliability (DfR), design for manufacturability (DfM), design for testability (DfT), and design for sustainment (DfS) are the most common DfX practices used in the electronics industry. If you are not using a DfX methodology today, consider implementing just one of these proven techniques.

Ansys has a collection of useful resources from our reliability experts to help you with your DfR challenges. Explore our Design for Reliability Resources.