-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Discover how an end-to-end model-based toolchain helps one automaker sort through system safety and complexity to advance automated steering capabilities.

While we’re not there yet, recent statistics suggest that mainstream acceptance of self-driving cars, rideshares, and delivery services may be just around the corner. According to the McKinsey Center for Future Mobility, autonomous driving could create $300 billion to $400 billion in revenue by 2035. This is good news for original equipment manufacturers (OEMs) and tier suppliers already invested in autonomous vehicle (AV) development. However, their success depends on several things, including the acquisition of new technological capabilities and the ability to address concerns about safety.

In the development of its advanced electronic power steering (EPS) system, Volkswagen intends to keep pace with a rapidly changing automotive landscape and its evolution to automated driving. The company relies on Ansys software to quickly bring it up to speed on EPS performance and safety to meet requirement thresholds while enhancing the precise, responsive handling that the brand is known for.

“The software tooling we developed especially for the use within our safety-critical development projects adds value to our toolchain,” says Dr. Johannes Grau, head of software systems and tools at Volkswagen AG. “Ansys products are a crucial part of our qualification foundation.”

Building on Automotive Expertise With the Future in Mind

Today’s EPS systems are more complex, with the ability to enable wide control of the steering process in different scenarios. Consequently, modern cars are capable of many automated functions already, including lane-keeping assist and temporarily automated driving in highway scenarios, self-guided parking, and even automatic driverless summoning.

Looking into the future, the next evolutionary step will be a steer-by-wire system: a system with no mechanical connection between the driver and the front wheels. These steering systems will enable highly automated driving (SAE Level 3+) and eventually evolve to driverless control without a steering wheel or human fallback. This perspective demonstrates a need for fail-operational systems that maintain vehicle control in all possible scenarios.

Steering system development is important work for Volkswagen, as ride and handling are qualities largely defined by steering feel. Any operational variance often comes down to differences in fractions of milliseconds as a function of vehicle software. These seemingly undetectable differences still unconsciously felt by drivers today frequently lead to clear judgments about performance. With automated driving, a lack of driver input makes this evaluation infinitely more complicated.

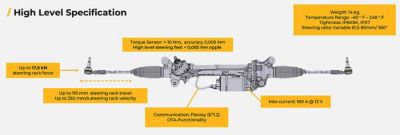

Currently, Volkswagen is developing an advanced modular steering system that can be integrated into its Premium Platform Electric (PPE) vehicles. This additional software component helps deliver a customizable “sport” feel, which is crucial to the driver experience. Notably, the steering system software will need to deliver behavior that could be applied to model-specific experiences yet remain consistent with overall brand expectations for performance across the PPE lineup. In doing so, Volkswagen mitigates on-road risks associated with the AV function, including a sudden loss of steering assistance or unintended steering.

To meet the complexity required to execute successful EPS development in an automated driving environment, testing was needed across multiple domains and multiphysics. System hardware, software, and mechanics must all be considered. It’s a monumental task for the approximately 150 Volkswagen engineers responsible for testing, validation, and verification of more than 8,000 requirements against a small, cost-efficient electronic control unit (ECU) generating 750,000 lines of code.

Complicating matters, the execution of all the test cases needed for back-to-back analysis of software system components takes more than 24 hours. To remain competitive in terms of both time and cost, Volkswagen needed to step up the pace in the streamlining of both processes and products.

“So, you have high complexity and high variability in a solution that needs to be very adaptable, but it also needs to be cost-sensitive, and it needs to be safe,” says Soeren Schreiner, senior application engineer at Ansys. “Safety is the factor that makes up most of the development cost.”

High performance: Volkswagen Premium Platform Electric (PPE) steering system

Achieving ISO 26262 ASIL-D and ASPICE L2 Compliance in a Single Toolchain

Autonomous technology relies on a combination of hardware and software to perform without driver input. In this instance, AV hardware is responsible for data collection, which is organized and compiled by the system software. This information is then processed via machine learning algorithms, or lines of code trained to interpret real-world scenarios.

To make a case for safety, Volkswagen engineers must actively prove they developed system software following mandatory safety standards. It requires compliance with ISO 26262, an internationally recognized standard for functional safety of electrical or electronic vehicle systems issued by the International Organization for Standardization (ISO). ASIL-D is the element of ISO 26262 that establishes the framework used to assist development of safety-related electrical and electronic (E/E) systems like EPS.

Additionally, Volkswagen’s steering system must comply with ASPICE L2 requirements. ASPICE defines best practices for embedded software in automotive development. At Level 2 (L2), it verifies that work products can be reliably delivered that nearly or entirely achieve ASPICE standards.

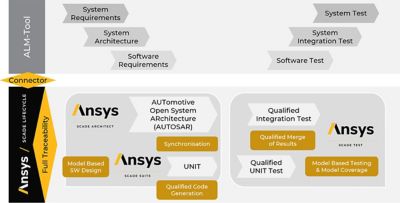

With help from Ansys SCADE Architect, SCADE Suite, SCADE Test, and SCADE LifeCycle development tools, it was possible to create an end-to-end model-based system and software design toolchain. The new toolchain supports Volkswagen in developing and deploying software efficiently while adhering to ISO 26262 ASIL-D and ASPICE L2 safety constraints as part of a highly complex and safety-relevant system.

“What we developed with Volkswagen is a very efficient and very flexible workflow,” says Schreiner. “This process enables us to specify and maintain complex multilevel software architecture models that are automatically synchronized with the software design models and functional test projects, all while enabling full requirements traceability.”

In facilitating the toolchain, SCADE Suite and SCADE Test software also reduced the number of activities necessary for Volkswagen to achieve compliance.

“Using software development tools where software tool qualification is part of the tool development adds value to our toolchain,” says Grau. “Qualified tools like Ansys SCADE Suite software introduce possibilities to reduce review effort within our safety-relevant development process.”

Safety-critical development processes: Volkswagen PPE steering system

Cracking the Secret Code With SCADE Software Solutions

Software in the SCADE platform was central in establishing Volkswagen’s model-based EPS system and software design toolchain. The following features make it uniquely positioned to advance the safety of autonomous vehicle function:

- Fully qualified code generation, model-based testing, and reporting, which allows Volkswagen to claim that all ISO 26262-relevant activities on the model level (testing, coverage, reviews) do not have to be repeated for the source code. This enables engineers to skip back-to-back tests normally required to demonstrate how a model behaves, as indicated by the code.

- AUTOSAR, or AUTomotive Open System ARchitecture-compliant software generation, which develops and establishes open, standardized architecture for ECUs for greater scalability. This standard is used mainly for fitting interfaces together, which enables components built at different companies or tier suppliers to be assembled and successfully communicate with each other.

Learn More

Ansys delivers state-of-the-art tools that derisk the safety-critical software certification process for OEMs in SCADE Suite software, an ISO 26262-qualified model-based development toolchain.

Sign up for our latest webinar, ISO 26262 Safety Analysis: Streamline Your Path to Functional Safety, to learn more.

Just for you. We have some additional resources you may enjoy.

“The software tooling we developed especially for the use within our safety-critical development projects adds value to our toolchain. Ansys products are a crucial part of our qualification foundation.”

— Dr. Johannes Grau, head of software systems and tools, Volkswagen AG

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.