-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

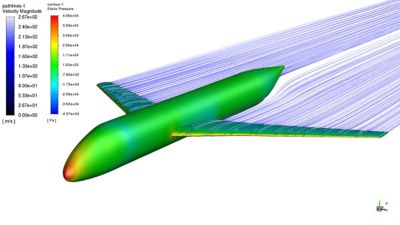

Simulation process and data management (SPDM) should not be considered just a tool for design teams, but rather it should be embraced as a strategic approach to how engineering teams can transform and operate. SPDM streamlines workflows, enables collaboration, manages data, and leads to a digital thread. Allowing organizations to make better decisions and stay ahead of the competitive market is a critical component to competitive advantage.

Investing in SPDM is beneficial to long-term success, particularly as products become more complex and industries demand rapid innovation and quicker time to market. Although it has become essential that organizations use simulation during the product development stage, they often struggle with how best to manage simulation data in an effective manner. SPDM offers a solution to many of these challenges, including business process management, better collaboration and communication across distributed teams, visibility into simulation results without the assistance of an analyst, traceability of data, and enabling the digital thread.

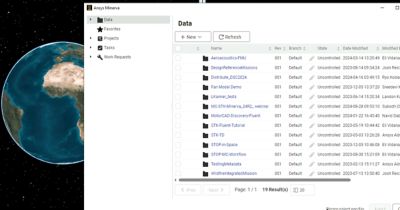

Ansys Minerva simulation process and data management (SPDM) software is an enterprise-class product capable of global deployment.

Streamline and Boost Efficiency

With the 2024 R2 release, Ansys Minerva SPDM software has enhanced simulation parameter management, allowing users to have a standardized way to effectively manage simulation parameters across any organization. People can use a parameter document as an input file and drive parameters in many applications, including Ansys optiSLang process integration and design optimization software, Ansys ModelCenter model-based systems engineering software, and the Ansys Workbench simulation integration platform. With the ease of managing parameters in a typical file view in Minerva software and as an input for running the application, a user can expect accuracy and consistency with simulation results. With this improvement in efficiency, engineers can focus more on innovating and solving problems that will enable quicker iterations and faster time to market.

Minerva software was designed by simulation engineers for simulation engineers.

Verification Plan and Reporting

As part of enhancements to verification plan and reporting functionality in Minerva software, organizations will benefit from a seamless way to integrate verification plans into their simulation workflows. It enables organizations to easily generate reports configured to specific criteria and to validate simulation results. Users can associate verification plans with a particular application, and whenever the application runs, the verification plan is executed against the job output. This enables users to instantly verify results as part of the simulation workflow. Accurate, reliable simulations are viewable and easily verified, supporting better decision making.

Revolutionize your product development process by efficiently managing simulation data, making it easier to access and reuse critical insights from past projects.

Build Robust Business Process Management

Simulation business process management in Minerva software provides a robust, configurable business process engine designed to adapt to simulation workflows and their iterative nature. In this release, engineers can convert a task to be automated while working on the work request either from the properties panel or from the task item view. Additionally, there is a read-only mode for the property panel for selected nodes in a workflow. New icons also have been added to clearly identify the assignment of single users or multiple users, along with reviewers.

Enable a Digital Thread

In the era of digital transformation, integrating simulation data into the broader digital thread of an organization is vital to success. SPDM enables the digital thread by connecting simulation activities with other product life cycle processes, and SPDM ensures that simulation data is aligned with design, manufacturing, and verification and testing. When simulation data is accurately managed and accessible to all stakeholders, organizations can gain efficiency and leverage the full potential of their simulation activities. Ultimately, this will lead to better collaboration, improved decision making, and the ability to stay competitive in the marketplace.

Start your SPDM journey today with Minerva software. Request a business process assessment to see how your engineering team can benefit.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.