-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

November 24, 2021

Managing Materials to Achieve Sustainability Objectives

Sustainable product design and development is on the minds of consumers and corporate board members alike, but the work of engineering teams behind product development is where those thoughts can be turned into action. In part 1 of our sustainability series, “The Impact of Materials on Sustainability,” we talked to the co-founders of Granta Design, now Ansys Granta, about the impact materials have on the environment, consumers, manufacturers, and the products themselves. Now let’s focus on how companies can better manage materials information to achieve their own corporate sustainability goals.

Building an Engineering Framework to Support Corporate Sustainability

Many companies have made commitments to achieve carbon neutrality. At the same time, consumers have their own vision of sustainable product design and development that they weigh against convenience and value. As a result, engineering teams are tasked with adopting a wider point of view.

Some global manufacturers have taken a holistic approach to decarbonization and resource protection through climate protection, the economical use of energy, the efficient use of environmentally friendly materials and the principles of recycling management, all of which complement each other.

A critical component of manufacturers’ sustainability goals is material selection. From this perspective, sustainable products evolve from a materials standpoint. Rather than being removed from the market altogether, they become part of a circular economy during which they can be reused, re-purposed, or recycled. Ultimately, the measure of success begins in the design phase, where an understanding of the carbon impact of materials is critical to material selection. Rather than focusing on materials, however, many companies begin with sweeping assessments of their carbon footprint, from water usage to energy consumption needed to manufacture a product, without posing materials questions early on.

Managing Materials Information with Granta MI

Making materials data available early in the lifecycle can help manufacturers understand the impact of raw materials on their products, the environment, and the circular economy. To this end, manufacturers need scalability and the right framework to gain insight through material data. Ansys Granta MI offers access to an extensive digitized collection of material information, as well as the framework and tools needed to manage material information and share it at all levels of an organization.

“Using Ansys MaterialUniverse in Granta MI to create material libraries from a restricted substances point of view allows manufacturers to link restricted substances and materials together to control material strategies at the design phase,” says Benedikt Duerbeck, Application Engineer, Ansys. “In the short term, with in-house design parts, Granta MI helps manufacturers to manage restricted substances and ensure product compliance.”

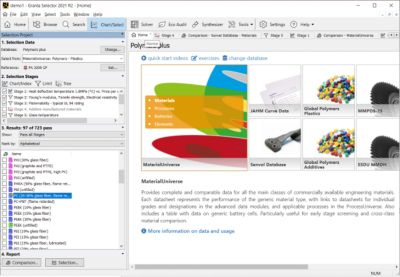

Ansys' MaterialUniverse in Granta Selector

For many manufacturers, the way they define a material is within the text field of a CAD model. To achieve compliance, manufacturers must refer to these drawings to identify the name of the material, then look to another source, such as a spreadsheet or enterprise resource planning (ERP) platform to extract additional information. Granta MI provides manufacturers with a centralized web-based infrastructure, allowing searches by material name, type, or properties to quickly retrieve ecological information for that material, without having to sift through data from various sources. It is a scalable solution that enables users to create, control, and store material data, then seamlessly integrate it with leading CAD, CAE, and PLM systems for enterprise-wide consistency.

“Using Granta MI, downstream users can take advantage of a built-in ID or link that will identify the exact material or list of materials used for a component’s design, with the relevant eco properties that can be enabled through the gateway or relevant API that connects Granta MI with most design, simulation or PLM tools,” says Alexander Berry, Application Engineer, Ansys.

Of course, there are manufacturers who are not actually working with materials, but with bought parts, and are not aware of the materials involved. For vehicles with digital screens included, for example, it is the manufacturer putting the screen in the vehicle who is responsible to make sure it is compliant rather than the manufacturer of the screen. In this case, the OEM must obtain supplier declaration statements regarding no-conflict materials. The imperative is for manufacturers to identify the materials used in these components to build more awareness around buying decisions. Integrating Granta MI with their enterprise information systems, manufacturers can make information coming out of supplier declaration statements accessible among other material properties early in the design phase.

Mobility Shifts to Electrification via Smarter Material Choices

The sustainability rubber meets the road, quite literally, in the automotive sector. The impact of sustainability is on display as automakers are phasing out gasoline- and diesel-powered engines in favor of battery power to reduce CO2 emissions. As electrification accelerates, so will the emphasis on CO2 reduction during the in-use phase of the product to achieve sustainability. Once that’s been reduced, the next step is net zero, requiring manufacturers to look at carbon neutrality from a materials perspective, such as the embodied energy and CO2 footprint for manufacturing parts, assemblies of parts or products.

Further, with the trend towards electrification in both the automotive and aerospace worlds, the shift from in-use to embedded energy over life becomes more significant. The product’s materials then become the largest contributor for embedded energy. This makes material management and selection a key component of determining a product’s CO2 over its life cycle.

The overall importance on material selection will increase post-electrification

“Material selection and strategies become imperative to enable continued reduction of energy and CO2over the life of a vehicle, with clear data around the types of material used being a driving factor in future vehicle design,” says Michael Lough, Senior Product Manager, Ansys. “From a design point of view, this puts Granta MI capabilities into sharp focus, allowing automakers to create data around raw materials, then swap-out and select the appropriate replacement materials with CO2 emissions and other sustainability factors in mind. With the help of Granta MI, automotive manufacturers can gain an understanding of material data and its impacts on sustainability and wider societal factors to formulate the right strategy for their products.”

Tsuyoshi Ito, assistant chief engineer working for Honda Motor’s Automobile Operations, recognized the importance of materials in automotive development, then began to build a materials management information system himself before recommending his company license Granta MI. With the help of the software, Honda Motor created more sophisticated materials information they can use to drive the adoption of lighter materials for engines and bodies.

“I compared Ansys Granta MI to other similar database software in terms of input, display, search, output, management and cost,” Ito says. “Because of its huge comparative advantage, including extra functions to automatically create a link between records and overlap graphs contained in multiple records, we chose Granta MI.”

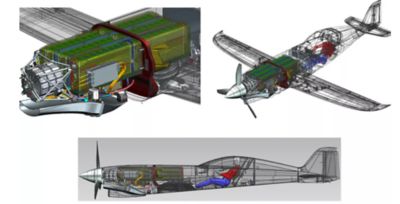

The aerospace industry is also considering the impacts of materials on aircraft electrification as they work through the challenges of cleaner energy production. In their effort to introduce the world’s fastest zero-emissions aircraft, for example, Electroflight, in partnership with Rolls-Royce looked to Ansys for help optimizing a 1,047-pound (475 kg) battery cell holder for structural strength, thermal management, and other critical performance criteria. By using Ansys Granta Selector, the Electroflight team was able to rapidly answer complex questions regarding the optimum material, given mechanical, thermal, and electrical resistivity requirements. Further, they were able to compare the environmental and regulatory impact of their selected polycarbonate to effectively assess its impact on overall sustainability to optimize their aircraft design and reduce their carbon footprint.

The battery cell holder in the Electroflight aircraft required careful material selection. Source: Electroflight

The impact of sustainability reaches far beyond mobility. As we look to the future of sustainability in manufacturing, one of the biggest challenges is clearly materials management, from production to in-phase use, and end-of-life disposal. Granta MI material data management software is helping manufacturers to store, control and analyze materials reference data so that they can make more intelligent decisions about product development and reach their environmental goals.

To learn more register for our Ansys Material Intelligence Day event which is now on-demand. We have a track dedicated to Environmental, Social, and Governance where you’ll be able to hear more about how Granta MI customers are tackling the challenges of sustainability.