-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

December 24, 2021

Supporting Sustainable Antenna Design in Wireless Energy Harvesting

The movies may be too many to mention, but the scene is always the same. A group enters an enormous warehouse that seems to go for miles, walking down aisleways past endless rows of crates, trying to find an artifact that holds the key to solving an important mystery. Fortunately, this is largely a work of fiction, as sophisticated tagging systems have become an industry standard in warehouse asset management. UWINLOC, based in Toulouse, France, provides a unique indoor location system for more efficient asset management, digitalization, and location. It’s the only internet of things (IoT) indoor location solution that uses battery-less tags. The tags enable plant and warehouse managers to tag assets, reduce delays, track large product volumes, and optimize stock flows.

This unique solution uses a combination of battery-less tags with wireless beacons and a software platform to reduce costs and increase efficiency of commodity flow management for all industries. To support the energy harvesting, battery-less operation requires a specific antenna design. UWINLOC took on this challenge, in collaboration with CADFEM and Ansys, drawing on their simulation expertise and reliable simulation solutions using Ansys HFSS. Ansys, along with CADFEM France, provided support and services to ensure UWINLOC achieved the best use of simulation.

Using HFSS Simulations to Enhance Antenna Development

Barcodes, QR code, and RFID (radio frequency identification) tags are widely used to manage production flow within the warehouses, despite some inherent flaws, such as short read ranges, or, in some cases, poor read accuracy. RFID is usually thought of as being a passive technology, generally with no batteries, simply reflecting radio waves after being excited by an energy source. However, RFID can also be active, allowing for greater transmission distances facilitating information such as asset position and movement. Active RFID in "real time" terms is usually achieved with a transmitter powered by an embedded battery, making it much more effective. However, it is also more expensive as it requires frequent costly, labor-intensive maintenance with associated battery exchanges. Additionally, there are sustainability issues around battery disposal resulting in greater costs and environmental questions.

One of the biggest challenges UWINLOC engineers faced during battery-less tag development was how to achieve a significant reduction in the number of power sources while maintaining their performance within the warehouse. The goal was to design the smallest antenna with the highest energy collection capability range, considering life cycle, quality, and product reliability without compromising overall performance. Overall costs and time-to-market were equally critical. Leveraging Ansys’ simulation know-how and HFSS simulation software, UWINLOC set out to find a reliable solution.

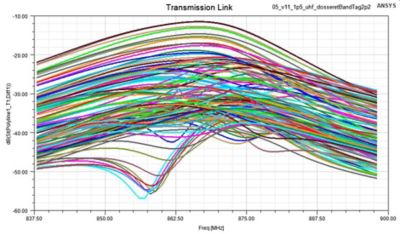

The faster and more efficient the tools can be to design an antenna that performs the best, the better energy can be harvested further, from a few meters up to 20 meters. Antenna has a certain gain in a certain direction, so the solution works in one direction, which makes harvesting difficult to achieve. Ansys HFSS tools are helping with this effort while eliminating the need for prototypes. HFSS enables UWINLOC engineers to go in new ways with multiple antennas through careful analysis and design, eliminating any concerns about energy harvesting and signal orientation.

René Stoll is the RF/UWB senior R&D engineer and antennae expert in charge of the development of the UWINLOC tag solution and has significant experience with this technology. Back in 1991, Stoll was hired by Hewlett Packard to help support the pre-release of HFSS, a software he had used during his university years. He was very familiar with the benefits of HFSS and eager to put his skills to use to tackle this design challenge. His goal was to develop a complex conjugated antenna for both ultra-high-frequency (UHF) and ultra-wide-band (UWB) technologies.

“What we are particularly focused on when building complex conjugate antennas is accuracy,” says Stoll. “When you are working in this environment, the smallest deviations are magnified, and choosing the right solver is especially important. HFSS enables us to develop next generation compact integrated antennas to drive wireless energy harvesting to a new level. I would not have been able to design what I set out to do without a simulator like HFSS.”

Achieving Optimal Antenna Placement with HFSS

For Stoll, good simulation tools are essential to develop antennae integrated into housings, even plastic ones, because of the direct influence of metals and dielectrics due to their proximity. Depending on the wavelength, the surroundings of the boxed antennae also influence the radiation properties significantly. The environment needs to be analyzed precisely since the link margin, or the difference between minimum expected power received and receiver sensitivity with harvesting is much less than in a regular communication system.

“If you start with parameterized models using HFSS, a sweep of geometric position can easily reveal optimum placements,” says Stoll.

Without Ansys simulation tools, the development of the battery-less tags would have been much more expensive and taken much longer. Using HFSS also resulted in 80% less prototyping, thus significantly reducing the elapsed development time. HFSS also enables Stoll to freely import and export his designs from other systems.

“I import a GDS file of my design into HFSS,” says Stoll. “That way I can work very efficiently to generate designs with very few adjustments. It’s a key feature that allows me to seamlessly import designs, then simulate them and document the results with detailed data illustrated by good pictures and nice graphs.”

Engineering A More Sustainable Solution

The value proposition of the UWINLOC battery-less tag is unique to asset tracking and location. Accurate digitization and location information traditionally require active battery powered systems which are generally much more expensive to maintain. Besides the added expense, the batteries tend to last one to two years at most, which may seem trivial with 10 or 50 tags. If thousands, or even millions of tags are involved, scalability becomes a much bigger challenge as do managing environmental impacts, including battery recycling and disposal. The energy to produce just one battery is three times greater than the energy expended by the battery tag over a lifetime. With the help of HFSS simulation software, UWINLOC delivered a sustainable tagging solution with the best performing antenna refreshing rate that relies on energy harvesting, rather than battery power for accurate asset location.

“HFSS is a faster, more efficient tool we can use to design an antenna that performs the best, allowing us to harvest energy further, from a few meters up to 20 meters,” says Stoll. “This represents a huge innovation, and the software is helping.”

As for the future of asset tracking location solutions, UWINLOC continues to look to Ansys and CADFEM to develop and produce best-in-class, eco-friendly asset management solutions. Discover how HFSS is helping companies like UWINLOC transform antenna technology through simulation.