This is the first in a series of “Ask the Engineer” blogs. Get a glimpse into how Ansys helps a NASCAR engineer improve safety along the wall.

In the world of stock car racing, one driver’s tactics can unexpectedly take others out of a race. That’s exactly what happened in October at Talladega Super Speedway, when an aggressive push from Alex Bowman led to Ryan Blaney’s late-stage crash.

It was that push that sent Blaney’s car spinning into a SAFER (steel and foam energy reduction) barrier, jeopardizing his chances at the 2024 title. On average, NASCAR race cars have the potential to reach 190 to 200 miles per hour, yet Blaney managed to walk away from a chaotic scene unharmed due to these life-saving inner and outer barriers circling the track.

Was it luck, engineering, or a bit of both? In this instance and many others, SAFER barriers, also known as soft walls, have played a definitive role.

SAFER barriers are created by the vertical stacking and welding together of 8-inch square structural steel tubes to form 20-plus-foot-long, 40-inch-high modules. Internal steel splices join them together to build a continuous wall that is then typically placed in front of a concrete barrier. Retention straps serve as an anchor between the SAFER barrier and the concrete wall behind it. Trapezoid-shaped foam blocks are then placed between the concrete barrier and the steel wall for energy management.

We recently had the chance to talk to John Patalak, vice president of safety at NASCAR. His team uses LS-DYNA nonlinear dynamics structural simulation software for placement optimization of SAFER barrier modules to reduce vehicle accelerations for track-specific configurations. This includes the reconstruction of specific on-track crashes to identify the potential for driver injuries, then applying this knowledge to realize risk reductions on the racetrack.

Question: How likely are impacts in NASCAR compared with everyday driving?

John Patalak: We have minor contact between race cars on the racetrack all the time. Typically, those cars either come down pit road and get new tires and continue on or bypass pit road altogether. We’re not usually interested in those contact events, as they’re not particularly injurious. We try to discriminate those out of our dataset by requiring trigger thresholds in our data recorders.

John Patalak, vice president of safety at NASCAR

A few years ago, we did a statistical study based on black box data coming out of the car. We pulled about 10 years of data to understand the number of contact events that qualify as crashes occurring in our different series. To be fair, we chose to look at crashes per mile raced, because you might race in an event that’s 250 miles or 600 miles long. Then there’s the format and the configurations of the track, among other things to consider.

Based on the data, when we looked at the full-time NASCAR drivers during this time period, they experienced 134 times more crashes per mile traveled than the motoring public. Yet, these same drivers experienced over nine times less injuries per crash. So they crashed way more often, but their injury per crash was substantially lower.

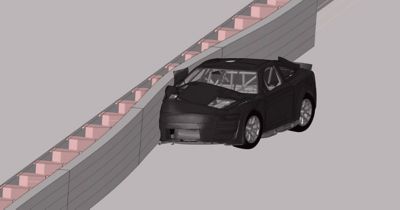

Using LS-DYNA nonlinear dynamics structural simulation software, this video shows a 130 mph simulated crash into a SAFER (steel and foam energy reduction) barrier.

How do SAFER barriers support NASCAR’s overall safety strategy?

Patalak: They’re an integral part of a multipart safety strategy in NASCAR that also includes black boxes for crash data, driver restraints — including full-face helmets, head and neck support (HANS) devices, improved seatbelts and seats — and crashworthy vehicle designs. The SAFER barriers have had a huge impact in lessening vehicle impacts along the wall.

The SAFER barrier system was actually developed by the University of Nebraska, Lincoln (UNL) at the Midwest Roadside Safety facility (MwRSF) with support and funding from IndyCar and NASCAR. LS-DYNA software was used to optimize or tune the barrier for the vehicle’s mass and the speeds at which it could impact a portion of the wall. As time went on, we’re still using LS-DYNA software, trying to find more improvements in the overall design.

What happens when a race car hits a SAFER barrier?

Patalak: Consider a race car approaching the wall at, let’s say, 150 miles per hour. Whether the wall is concrete or SAFER barrier, that velocity is the same. When the car hits the wall, it begins to slow down. When the car leaves the wall, the car has changed its velocity — let’s say it’s now going 100 miles per hour. During both a concrete wall and SAFER barrier crash, the vehicle had to change its velocity the same amount, in this case 50 miles per hour.

What makes the SAFER barrier so effective is that it displaces during the crash, much like the car does as it crushes. In both cases, we are adding time over which the velocity change is occurring, so the car is making that 50 miles per hour change over more time than it would if it impacted a concrete wall, which doesn’t displace. The vehicle acceleration during the crash directly influences the forces on the driver’s body. By adding more time during the velocity change of the crash, the SAFER barrier is very effective at reducing the peak accelerations experienced by the car and the driver. The lower the acceleration, the lower the forces on the driver’s body.

How does LS-DYNA software lead to improvements in barrier design?

Patalak: We’ve used LS-DYNA software to study the SAFER barrier and how to implement it at racetracks. We occasionally have race weekends where we share the racetrack with other series. Other series vehicles may be much lighter than NASCAR vehicles, or they may go faster, so their impact conditions to the SAFER barrier are much different than NASCAR vehicles.

Last year, we used LS-DYNA software to study various impact angles at different speeds to soften the wall and get as much displacement out of it as possible. Working with Elemance LLC and UNL MwRSF, we did this analysis for the first time at the Los Angeles Memorial Coliseum for one of our opening events of the season, the NASCAR Busch Light Clash at the Coliseum.

It’s a shorter track, and the speeds are lower. Analyzing the impact angles there enabled us to remove every other foam block within the SAFER barrier to optimize the SAFER barrier without expensive physical testing.

A SAFER barrier. Image credit: Getty Images

Can you share some benefits of using LS-DYNA software in your work?

Patalak: Based on the simulation data we’re getting, our confidence level using the software is high. We can start to study other problems that previously were cost-prohibitive in terms of testing, like the alternate spacing of foam blocks. Without LS-DYNA software, it’s the sort of testing that you’re really not sure can be justified otherwise in terms of cost, because you don’t know what you’re going to find or if the project is even worth it. In a simulation environment, however, you can run that assessment for much less.

LS-DYNA software enables us to explore and see what the important factors are and what really makes a difference in barrier design. And in some cases, we will go run physical crash tests to verify and validate our results. For some projects, our confidence level is high enough to proceed without physical tests. For example, we were able to implement changes of the foam block spacing at the Los Angeles Memorial Coliseum last year without any empirical testing.

How do you reconstruct on-track crashes leveraging virtual human body models in LS-DYNA software to prevent head injuries?

Patalak: Typically, we’ll start with human body models because we have human drivers in our race cars. In many cases, the drivers wear mouthpiece sensors that are recording the acceleration and rotational velocities of their heads. Working together with the Center for Injury Biomechanics at Wake Forest University and the Wake Forest School of Medicine Biomedical Engineering groups, NASCAR introduced these mouthpiece sensors to capture on-track driver head kinematics. We will look at those outputs, then run our human body models to make sure that from a baseline standpoint we are predicting what the empirical data showed.

Once we are closely aligned with that data, we can start to tune things like helmet fit, helmet materials, seat stiffnesses, and head and neck restraint tether lengths. Using our engineering intuition and education, as well as the laws of physics, we can begin to answer some basic design questions. For instance, if we modify the stiffness of the head foam, can we reduce the head acceleration that the driver experienced?

We’ll run through a bunch of different iterations and study it that way. All this work is done in a virtual modeling environment. If we find a change or iteration in design that might be a benefit, we will go and validate it empirically before we incorporate any meaningful changes to the restraint system.

Ansys LS-DYNA software enables NASCAR to explore barrier design.

Considering your work at NASCAR over the years, how significant is the SAFER barrier?

Patalak: It’s been roughly 20 years or so since the SAFER barrier was first implemented on the track. Today, I would include this technology in my top five greatest hits of motorsport safety improvements. In fact, Dr. Dean Sicking, who at the time was leading the group at the University of Nebraska responsible for the SAFER barrier, is being inducted into the NASCAR Hall of Fame this February.

It’s a landmark achievement. If you compare this technology to concrete, you’re looking at anywhere from a 30% to 80% reduction in peak acceleration values experienced by the vehicle. It’s a massive improvement now. Today, we’re still using LS-DYNA software to squeeze out maybe another 5%, as the tool is much finer and more precise now.

We want to thank John Patalak for his contribution to this blog series. If you would like to learn more, make sure to check out our blog for a more in-depth look at how NASCAR is using human body models in LS-DYNA software to significantly reduce injury on the track.

Just for you. We have some additional resources you may enjoy.

“Without LS-DYNA software, it’s the sort of testing that you’re really not sure can be justified otherwise in terms of cost, because you don’t know what you’re going to find or if the project is even worth it.”

— John Patalak, vice president of safety, NASCAR