-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

February 13, 2024

Danfoss Drives Supports Sustainability and Digital Transformation by Democratizing Simulation

With sustainability concerns impacting nearly every global industry, companies are seeking ways to reduce energy consumption throughout their organizations. In fact, energy conservation is a key driver in the development of speed control devices for electrical motors. Even small changes in motor speed can improve energy consumption.

Alternating current (AC) drives help control the speed of electrical motors to match load demand and are used in a wide range of industries from material handling and processing to food and beverage. Danfoss Drives, a subsidiary of energy-efficiency powerhouse Danfoss, is focused on developing, manufacturing, and supplying AC drives, which can enhance process control, reduce energy usage, decrease mechanical stress on motor control applications, and optimize the operation of various applications relying on electrical motors.

To increase efficiency, optimize workflows, and improve operations, Danfoss Drives leverages Ansys multiphysics simulation internally and externally. During the design and development of its AC drives, the company democratizes simulation for its designers, developers, and engineers — including non-simulation experts — by seamlessly using Ansys Discovery across in-house teams. Beyond company walls, the team collaborates with customers to create solutions together. By making simulation more accessible and easier to implement inside and outside of the organization, Danfoss Drives supports sustainability and digital transformation.

In Ansys Discovery, you can test several design ideas in seconds. In these simulations, both light and heavy weight materials are analyzed to find the best structural fit for a control arm.

Embrace Simulation Across Teams

Danfoss Drives has been integrating Ansys’ solutions for more than 10 years.

“Optimization requires high-fidelity modeling and simulation,” says Janne Kuivalainen, Chief Technology Officer at Danfoss.

For example, Discovery combines high-fidelity multiphysics simulation and interactive geometry modeling in a single, easy-to-use tool. It’s also equipped to handle a broad range of engineering disciplines with capabilities, including structural, fluids, and electromagnetic analyses. By using Discovery, Danfoss Drives gains critical insights earlier in the design process and minimizes physical testing and prototyping, which saves time, energy, and costs while reducing material waste. In addition, virtual prototyping enables the team to explore hundreds of design concepts in a fraction of the time it takes to build and test physical prototypes.

The team also uses Ansys Mechanical for finite element analysis (FEA), Ansys Fluent for computational fluid dynamics (CFD), Ansys Icepak for electronics thermal management, and Ansys SIwave for signal integrity, power integrity, and electromagnetic interference (EMI) analysis.

Danfoss Drives’ VLT® Midi Drive FC 280 provides precise and efficient motor control for machine builders in industries such as food and beverage and material handling and processing.

“If I look back to the product itself, we have decided on more extensive use of modeling and simulation,” says Kuivalainen. “This depends very much on the different physics like thermal, vibration, and electromagnetic compatibility (EMC) simulations.”

Extend the Value of Simulation to Customers

In addition to internal digitalization, Danfoss Drives extends the value of Ansys simulation externally by collaborating with customers.

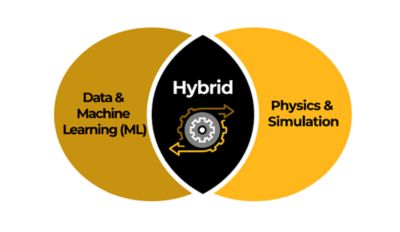

Ansys Twin Builder enables you create hybrid digital twins, which combine physics and data to achieve higher accuracy.

“We started to pivot systems in our own application development centers with a customer-facing platform,” says Kuivalainen. “We have physical locations where we can go to innovate and develop solutions with our customers.”

For example, Danfoss Drives communicates with its customers to understand their needs and offer hardware-in-the-loop (HiL) solutions based on those needs.

“With Ansys, we can democratize the simulation, making it more available, so that customers get the right support to get started,” he adds.

Outside of Kuivalainen’s team, other divisions at Danfoss are integrating Ansys Twin Builder, an open solution that enables you to create digital twins using hybrid analytics.

Essentially, hybrid analytics is a set of techniques and tools that combine physics and data to create a more accurate digital twin: the hybrid digital twin.

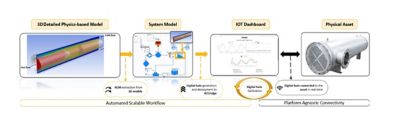

Twin Builder offers XIL integration, which supports co-simulation for HiL, model-in-the-loop (MiL), and software-in-the-loop (SiL) validation workflows.

Additionally, you can easily configure a connector with an Internet of Things (IoT) platform to send and receive operational data.

Twin Builder enables you to easily connect with Internet of Things (IoT) platforms to send and receive operational data.

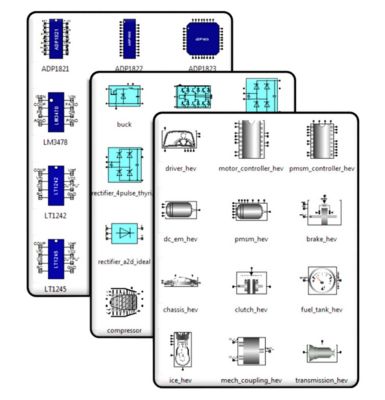

Another benefit of Twin Builder is its built-in, multidomain libraries. For example, you can model complete electronic systems using libraries of analog and power electronics components or use add-on libraries such as the Twin Builder Heating and Cooling library.

Digital twins enable predictive maintenance, resulting in cost savings and the optimization of an asset’s operation.

Explore Digital Transformation

So far, Danfoss Drives has met success by incorporating Discovery and other Ansys tools to meet customers’ needs.

“We can see how greatly we can help our customers to speed up productive development and run earlier full-scale virtual testing and performance assessments before they have any physical hardware realized for their product,” says Kuivalainen. “Simulation modeling helps customers to build better solutions.”

Twin Builder features built-in multidomain system libraries.

To explore user-friendly 3D modeling, request a free trial of Discovery. To learn how digital twins can benefit your operation, request a free trial of Twin Builder.

Read more about Danfoss Drives’ support of simulation and sustainability in Danfoss Drives: The Journey to Net Zero and Energy Efficiency, Manufacturing magazine, December 2023.