-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

December 27, 2018

Understand a Design’s Breaking Point with Simple Crack Propagation Simulations

When a crack appears in a part, it’s bad news. The crack could propagate and lead to part failure. Now, the whole thing needs to be inspected and/or replaced.

Engineers are tasked to fight the susceptibility of cracks. When cracks do inevitably form, engineers need to understand what has to be done to ensure the crack doesn’t lead to a part failure. These tasks are carried out using engineering simulation.

However, assessing these cracks can take a long time because making a mesh to simulate crack propagation can take days — even weeks.

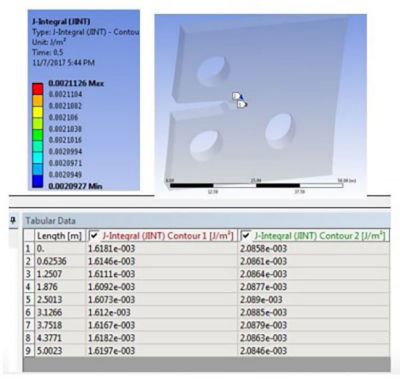

Pre-processing a crack propagation simulation in ANSYS Mechanical.

The longer engineers wait for a working mesh, the less time they have to iterate, replace or fix their part based on the simulation results.

Recently, Ansys Mechanical introduced the unstructured mesh method (UMM). This method will help engineers mesh their crack propagation simulation in minutes. This method will help to speed up the development of stronger parts.

The Challenges of Simulation Crack Propagation

Traditionally, simulating crack propagation means using hexahedral (hex) and wedge elements to capture the geometry of the crack and allowing the solver to run.

Ideally, the mesh would only involve hex elements and the solver would progress the crack through the mesh. The reality is that geometry is never that simple, and the crack’s path will not want to travel in the same direction as the mesh.

Engineers can simplify the crack’s geometry until they can capture its behavior with only hex elements. However, this leads to a loss of fidelity in the simulation.

Alternatively, engineers can use UMM. The method reduces meshing time by automatically generating an all-tetrahedral (tet) mesh at the crack’s front.

The Benefits of Using UMM to Mesh a Crack Propagation Simulation

Ansys found that UMM meshes achieve comparable results to an idealized all-hex mesh when simulating crack propagation.

The biggest benefit of UMM is that it can produce a mesh in a few minutes. As previously mentioned, traditional pre-processing methods can take weeks.

Engineers can use UMM to determine the rate the crack grows and the number of cycles until the part fails.

Ansys Mechanical users will also have access to the separating morphing and adaptive remeshing technology (SMART).

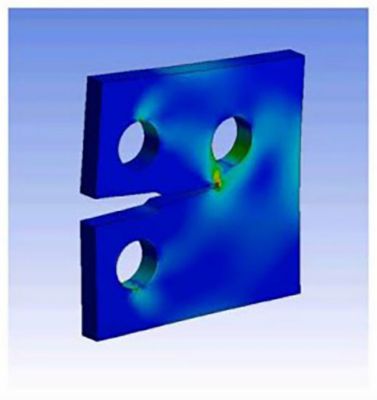

Crack propagation simulation is completed using SMART and UMM to mesh the part.

SMART interfaces with UMM to automatically remesh the part throughout the simulation as the crack progresses. This will maintain accuracy throughout the simulation without the engineer having to stop the solver and manually remesh the crack.

In other words, SMART will be a considerable time saver when simulating fracture mechanics.

To learn more about how to set up UMM or SMART in a crack propagation simulation, read the SMART Fracture white paper.