-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

September 26, 2022

When the Chips are Down, Ansys Ramps Up ISO 26262 Analysis

If you’ve been in the position of having to purchase a new vehicle recently, you may be painfully aware of how challenging it is to find one, thanks to semiconductor chip shortages. These shortages were caused by a number of factors over the past couple of years, including COVID-19 restrictions, transportation challenges, adverse weather events, and a recent war — all of which adversely impacted automotive supply chains. On top of supply chain issues, chip manufacturing challenges are compounded by new sensor requirements for advanced driver assistance systems (ADAS) and electric vehicles, which increase system complexity and safety concerns.

A new level of system complexity requires extreme creativity and agility from engineering and design teams to continuously update semiconductor chip designs supporting numerous automotive safety domains. Surviving these challenges — as well as the current supply chain issues impeding their production — requires automotive manufacturers to quickly ramp up ISO 26262 requirement-based analysis and testing to compete. Ansys software can help, offering new capabilities to address comprehensive functional safety analysis of semiconductors in alignment with ISO 26262 standards.

What’s So Important About ISO 26262, Anyway?

ISO 26262 includes criteria geared specifically toward safety-critical electrical and/or electronic (E/E) automotive systems and the components that make up these systems. ISO 26262 is needed to establish the fundamental framework by which system safety objectives are met. Without this standard, original equipment manufacturers (OEMs), Tier 1 suppliers, and other key stakeholders up and down the vehicle supply chain would be left to struggle with delivering a product or service that adequately supports vehicle manufacturing objectives for safety. Anyone working within the OEM ecosystem is generally subjected to them.

For example, a supplier of semiconductor chips — a collection of electric circuits and many components forming the basis of the circuitry that enables a vehicle safety system to function correctly — bases the production of these tiny, extraordinarily complex components on the safety functionality of an ADAS or autonomous vehicle (AV) system, as well as other system factors driven by customer requirements. But with numerous system aspects and stakeholders to consider, just how do these ADAS and AV systems come together to meet OEM objectives for safety?

ISO 26262 provides the roadmap for achieving these objectives, helping to align expectations for all involved. As with other ISO standards, ISO 26262 evolved in response to industry struggles of OEMs and Tier 1 suppliers to anticipate and meet requirements across many different components within a safety system. ISO 26262 imposes the standard guidelines and requirements on engineering processes to develop a host of safety-critical systems exclusively for automotive applications.

“So, if you want to define, for example, a power steering or braking system or any ADAS function, the OEM will set the scope of what is actually going to be developed,” says Dr. Michael Soden, a lead product manager at Ansys. “Usually, this involves the complete vehicle architecture before next-level analysis, which decomposes into the various subsystems. It is during the concept phase that the hazard analysis is made to understand what safety risk is imposed by the system you are developing. For any supplier, it is important to understand how their component fits into the overall system, especially when it comes to safety aspects.”

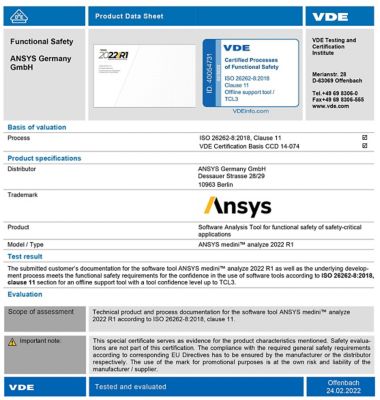

Official VDE certification of medini analyze 2022 for ISO 26262-8:2018 pertaining to supporting processes in functional safety of road vehicles. VDE is one of the largest technology organizations in Europe. They combine science, standardization, testing and certification standards to advance technology, and are associated with the highest safety standards and consumer protections.

Achieving Automotive Semiconductor Compliance in One Toolset

Complete electronics development flows downward through several predictable engineering phases, from the design phase at system level involving software all the way down to the actual system hardware involved. It also requires a significant amount of integration testing on the journey to produce the final product: the vehicle itself. There are a number of supporting processes that generically apply to testing throughout these development cycles, defined within a succinct process framework. ISO 26262 serves as that framework, which by itself has many requirements on what customers have to achieve; however, ISO 26262 certification is only as successful as the tools on hand. This is where Ansys medini analyze software comes into play, as it supports the ISO 26262 use cases of automotive semiconductor applications.

“Ansys medini analyze supports safety engineers as they go through this complete life cycle for hazard and failure analysis at various stages of vehicle development, in a tool which actually enables them to do the essential analysis quickly, efficiently, and confidently,” says Soden. “For these engineers, there’s a long list of action items and work products that need to be addressed as they relate to ISO 26262, and it’s often hard to understand the purpose of all the methods executed along a complete analysis cycle — from the early design stages at the OEM to semiconductor production occurring toward the end of the design cycle. Ansys medini analyze helps engineers sort out this complexity.”

Ansys medini analyze presents safety competency as a toolset. For example, if an engineer starts to design a safety-related system like automatic emergency braking, they must first define the scope and the functions of this braking system, including the different sensors involved, the actuators or brakes, and anything that interfaces with other systems, such as the steering system. The engineer will then go into various tools to conduct analyses using individual methods to assess malfunctions, such as a sensor failure across the system. Typically, this effort might involve Excel spreadsheets or failure modes, effects, and diagnostic analysis (FMEDA), or other point tools unconnected to the individual component and system design. Unfortunately, all these analyses are conducted in isolation of one another.

What's unique about medini analyze is that it's not just a point tool supporting individual methods in isolation, but an all-embracing toolset that combines all relevant methods in one chain. These methods are not arbitrarily combined but work within the notion of models expressed in SysML (System Modeling Language). The design is expressed first by the engineers involved, then all analysis is consistently connected to the design for an integrated approach to model-based systems engineering (MBSE) testing and analysis. To support this approach in chip development, medini analyze now incorporates ISO 26262 semiconductor standards in a comprehensive, model-based safety and reliability analysis approach, leading to greater consistency and efficiency in overall system design.

Customization in medini analyze also gives automotive customers the freedom to interpret analysis outside of ISO 26262’s specific framework, e.g. for application in industrial contexts along IEC 61508. The software can be adapted to customer workflows to find compliance in solutions that closely match their safety objectives at both the component and system levels, giving them the flexibility to design, create, and innovate.

Soden sees an immediate need for — and a viable future in — the use of medini analyze in the near term to support ISO 26262 chip design and analysis.

“Using medini analyze could bring significant cost savings to activities supporting semiconductor development, which is another good reason for manufacturers to streamline their processes in anticipation of future vehicle production,” says Soden.

Learn more about Ansys medini analyze software or get your free trial today!