-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

An era of unprecedented vehicle personalization is here. What will our travels look like, exactly? Marelli sees a future powered by dreams — of transparent overlays that can transform almost any interior surface into a customizable touch screen display and real-time exchanges with artificial intelligence-powered co-pilots.

It’s possibilities like these that make infotainment both a key brand differentiator and a significant safety hurdle for original equipment manufacturers (OEMs). All are driven by an insatiable consumer appetite for increasingly software-driven features and functionality, including advanced driver-assistance system (ADAS) platforms defined by minimalistic display interfaces and over-the-air updates.

Yet the net effect of these novel technologies is the exponential growth of vehicle complexity and the need for seamless system interoperability, or the ability for all the systems involved to work together safely, without fail. It’s a lot of effort to turn around novel technology at this level of complexity in a short timeframe while being validated against a slew of industry safety requirements.

To this end, Marelli is creating software-defined vehicle enablement platforms that take a simpler approach to hardware and software design. Ansys tools and solvers enable Marelli to meet OEMs where they are during development to help scale up platforms quickly. These same tools also help Marelli explore and develop new possibilities in vehicle infotainment and personalization for customers.

“We’re committed to empowering our customers through the smooth transition to centralized vehicle architecture,” says Luciano Saracino, head of the Mechanics and Optics Center of Expertise, Marelli Electronic Systems. “Our tailored solutions are designed to meet the demands of connected cars currently on the road, as well as automated vehicles of the future. Ansys helps us to deliver hardware design and manufacturing, as well as top-tier software development, integration, and validation services that satisfy industry standards for safety and cybersecurity.”

Passive safety standard requirement: head impact test ECE-R21/FMVSS201. In the design validation phase, Marelli tested the design on a special testing frame before the production validation phase, in which the display was mounted on a complete dashboard.

Simulation Tools and Solvers Deliver Robust Analytical Digital Twin Powers

Inside a cockpit, there are many different configurations for OEMs to test, subject to numerous safety standards. It was a challenge that inspired one customer to look to Marelli for support to optimize all the passive vehicle safety systems and components of a cockpit to help fulfill certain regulatory requirements.

Passive elements of a cockpit are generally evaluated for their ability to perform as intended (airbags and seatbelts, for example) or maintain their integrity (like the dashboard) upon impact.

To curb prototyping and costly physical testing, a digital twin was developed. A digital twin is an integrated data-driven virtual representation of real-world entities and processes, with synchronized interaction at a specific frequency and fidelity. In this case, the team replicated the cockpit in its entirety. The resulting digital model maintained a one-to-one relationship with the physical model in terms of strength, stiffness, and thermal behavior from a structural point of view.

Failure could be examined against every aspect of the cockpit — such as the steering wheel, cockpit displays, and air vents — basically everything inside. In this case, combining digital twins with the power of Ansys simulation enabled Marelli to model the performance of its infotainment systems in a variety of conditions within the context of the entire cockpit to ensure their reliability and functionality.

To this end, Marelli relies on a variety of Ansys tools and solvers, including:

- Ansys Discovery 3D product simulation software for geometry preparation and simplification

- The Ansys Granta Materials Intelligence (MI) platform for material selection and optimization of system components

- Ansys LS-DYNA nonlinear dynamics structural simulation software for impact and penetration testing, as well as airbag deployment and occupant safety

- Ansys Mechanical structural finite element analysis software for linear and nonlinear static simulations

- Ansys Speos CAD integrated optical and lighting simulation software for optical simulations of interior elements

“Ansys tools are fundamental for Marelli, helping us co-create designs and solutions with our OEMs and partners to achieve higher levels of personalization, facilitate innovation, and reduce time to market,” says Simone Calcopietro, head of simulations for the Electronics Mechanics Technology team at Marelli. “We can now develop custom-made solutions that fit all the project requirements and precisely align with our customers’ and users’ needs — experiences that strike the perfect balance between vision and usability.”

Optical lab measurement: Detailed evaluation of specific optical parameters is carried out.

Keeping It Together To Help Keep Everyone Safe

Considering the cockpit layout in its entirety is crucial to understanding passive safety with respect to infotainment elements of the cockpit. All must work together during a crash to maintain their integrity and keep everyone safe. An exposed edge, splintering glass, or a part that deforms or breaks free upon impact can prove fatal for occupants.

To do this, the design team uses Discovery software to deliver the geometry of all the components inside the cockpit to create the discretization of the model. What this means is that the geometry is transformed from something parametric to something that can be evaluated with finite element method simulation using multiphysics tools and solvers. In the process, materials are also identified, then assigned with help from Granta MI software.

“We assign all the properties and materials for each component discretization,” says Calcopietro. “For example, in the cockpit, we’re going to apply all the plastic properties or polypropylene with carbon fiber inside a component. We assign materials with help from Granta software to understand the expected behavior for each material, be it metal or plastic.”

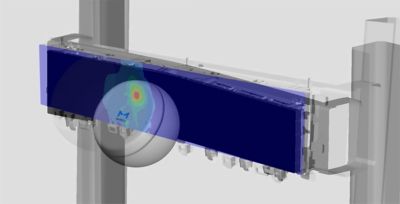

After this, the team creates the boundary condition for stress analysis using Mechanical software. In one instance, it was to test the impact of a steel ball hitting the middle of the dashboard to determine how the dashboard would withstand the load. The steel ball itself represented a human head and was used to understand the amount of deceleration proportional to impact that could result in critical fatalities for front occupants.

Additionally, the deformation of the dashboard was considered, as well as the net effect of this impact, using LS-DYNA software. For example, could such an impact cause pieces of the dashboard to detach and fly away, an event that may include splintering glass?

“We are able to simulate these effects in a very short period of time,” says Calcopietro. “So, 20 milliseconds, maybe 30 milliseconds maximum. This includes the evaluation of the stress inside the component, the plastic deformation, and the behavior. After that, we are double-checking the requirements against existing standards.”

Simulation of a passive safety requirement: head impact test ECE-R21/FMVSS201

Marelli Speeds Toward Automotive Safety 90% Faster With Ansys

Across the industry, a big factor impacting the success of automotive innovation is timing. For most OEMs, it’s a real scramble to keep up. This effect is trickling down the supply chain, as suppliers are faced with shorter development arcs requiring greater speed and agility to tackle unfamiliar, increasingly complex design challenges.

Simulation drives a faster, more robust development process for automotive solutions that can quickly satisfy market requests — so fast, in fact, that Marelli has successfully used Ansys tools and solvers to cut development by up to 90% in terms of both time and cost. It’s a big savings that can be passed on to customers facing the same pressures.

“Thanks to Ansys tools, we have realized a 25% reduction in product development cycle, 15% to 20% savings on engineering development costs, and the 15% to 20% improvement in product performance, to the satisfaction of our customers,” says Saracino.

Want to learn more about Marelli’s work with simulation? Make sure to check out our video interview with Marelli.

Just for you. We have some additional resources you may enjoy.

“Thanks to Ansys tools, we have realized a 25% reduction in product development cycle, 15% to 20% savings on engineering development costs, and the 15% to 20% improvement in product performance, to the satisfaction of our customers.”

— Luciano Saracino, head of the Mechanics and Optics Center of Expertise, Marelli Electronic Systems

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.