ANSYS ADVANTAGE MAGAZINE

DATE: 2018

Simulation Redefined

By Mark Hindsbo, Vice President and General Manager, Ansys

In today’s hyper-competitive, innovation-driven business environment, traditional ways of applying engineering simulation are no longer enough. Simulation must be used every day, on every product, across the entire product lifecycle, to study and improve every aspect of performance. Doing less puts your company at risk.

"Engineering simulation is becoming more pervasive in its ability to positively impact product innovation and performance, drive top-line growth and deliver end-user benefits."

For nearly half a century, Ansys has been instrumental in helping customers drive innovation with engineering simulation, while also reducing costs and product development time. From cars, planes and trains to consumer electronics, industrial machinery and healthcare solutions, Ansys software has helped create products that have transformed their respective industries.

While we are amazed by our customers’ achievements, we believe they represent only the beginning of the incredible value simulation can generate. Today, simulation is entering a new era, characterized by three fundamental changes:

- Simulation used to be a scarce resource applied in the design of only the most complex industrial products, but now is becoming integral to the design of every product.

- Product simulation examined single attributes: one physics, one component, one design. Now we explore a plethora of designs at the system level with interactions across multiple physical and digital domains.

- Perhaps most exciting, simulation is being leveraged not just for design validation, but from early ideation through manufacturing, operations and maintenance.

In short, engineering simulation is becoming more pervasive in its ability to positively impact product innovation and performance, drive top-line growth and deliver end-user benefits.

Because these trends are reshaping how Ansys develops its engineering simulation software — as well as how customers worldwide, in every industry, leverage our solutions — it is worth considering each of these changes in more detail.

A SIMPLE PRODUCT? NO SUCH THING

When engineering simulation debuted in 1970, it represented a novel capability — but one that required highly skilled engineering specialists to set up, as well as computing resources only available to the very largest organizations. As a result, it was almost exclusively applied to the most complex and costly engineered products, such as industrial machinery, cars and aircraft.

However, in 2018, there is no such thing as a simple product. Today, every design is being pushed to the limit to take advantage of composite materials, additive manufacturing and the high level of connectivity and automation enabled by Industry 4.0. The result is a new generation of smart, durable and sustainable products.

You might believe that engineering macro trends are only disrupting products such as cars, by increasing electrification and autonomy. However, this digital revolution is happening in every industry and for every product. Simulation is essential in this new world, because only by digitally simulating all the product options offered by these engineering trends can you gain the insight needed to innovate like the category leaders.

Today we see customers such as Mars, which makes Skittles® candy, use Ansys software to optimize its manufacturing processes by leveraging the same simulation sophistication as turbine manufacturers. And startup Nebia used the same equations that govern rocket exhaust to save 70 percent of water consumption in a showerhead. No product is too small, simple or inexpensive to benefit from simulation.

COMPLEX ANALYSIS FOR A COMPLEX WORLD

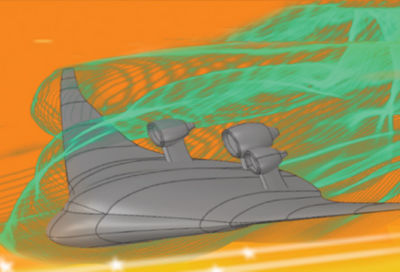

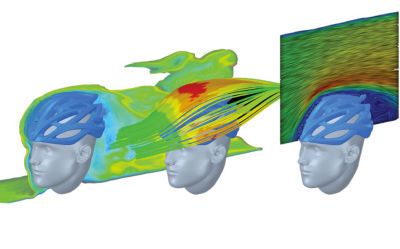

As we push for ever-smarter and more efficient product designs, we can no longer afford to only look at a single aspect of performance or a lone part in isolation. In the past, engineering simulation teams were likely to isolate just one critical physics — for instance, Formula 1 carmakers might have focused on the vehicle’s aerodynamics, which has a profound impact on speed and performance.

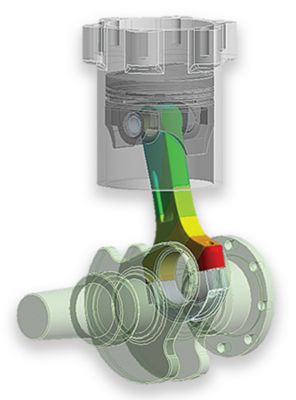

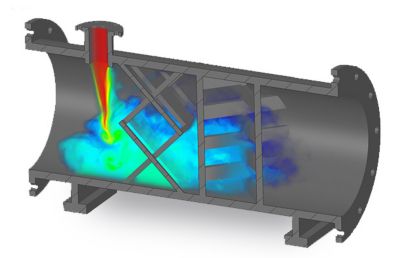

Today, thanks to improvements in simulation software, hardware and processing speeds, it has become much easier for engineers to study multiple physics and assess overall product performance. This is critical because, to use the Formula 1 example, overall speed and performance do not only depend on aerodynamics. The efficiency of combustion, the ability of the tires to withstand wear, the reliability of electronics — all of these factors, and more, affect overall performance. Because optimization in one area might lead to a trade-off in another, it becomes increasingly important to simulate all influences together. Today, 96 of Ansys’s top 100 customers worldwide use three or more physics solutions, applied across the Ansys platform.

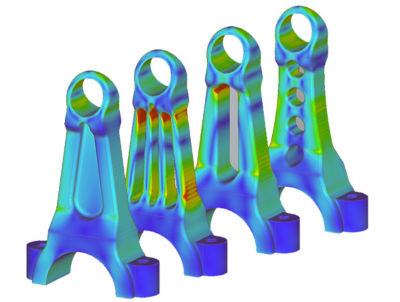

Improvements in computing power and simulation software also allow the evaluation of many more design options, to the point where the design process can be turned upside down. Rather than asking simulation to verify a specific design, engineers are asking simulation to analyze thousands of possible designs, early in the ideation process, to identify the optimal one. This is perhaps most obvious in topology optimization, where the engineer sets up, for example, the structural criteria for a part and simulation automatically iterates to find the best design.

Increasingly, simulation will start from the requirements and generate the design, instead of being applied after most of the design choices have been made. This is the only way to tame the complexity inherent in modern product design, and to capitalize on the opportunities created by the rapid innovation required to be successful today.

"The digital revolution is happening in every industry and for every product."

Pervasive Simulation for a Digital World

"Soon, leveraging engineering simulation pervasively will no longer be just a competitive advantage of the few, but an absolute imperative for all."

GENERATING RETURNS ACROSS THE PRODUCT LIFECYCLE

Probably the most important change today is a more pervasive, consistent use of simulation at all stages of a product’s lifecycle. Once a specialized activity wedged between initial design and physical testing, today simulation is recognized for the significant strategic value and financial returns it can deliver from the earliest design phases through the product’s working life in the field.

Even today, the majority of product decisions are made using rules of thumb, and simulation is primarily used by specialists within the engineering team. Others still rely on the most used engineering tool, which is Microsoft® Excel. As simulation advances to become as easy and as fast to use as Excel, this opens a whole new era of innovation, in which every engineer can benefit from detailed simulation insights at any time in the design process. When products are in the earliest ideation stage, designers can apply digital exploration to test their initial concepts and gain insights that lead to preliminary product designs targeted at meeting highly defined customer needs, as well as earning strong profit margins.

In a world where millions of rows of data are updated, calculated and charted in real time in Excel, and where Google gives us immediate access to billions of websites, it is almost incomprehensible that simulation is not equally accessible to every engineer. At Ansys, we are making breakthroughs with Discovery Live and other products to make this a reality. In a few years, it will be unimaginable to innovate without native and pervasive use of simulation by every engineer.

Simulation is also increasingly applied to the manufacturing phase, where it significantly improves the efficiency, cost-effectiveness and flexibility of production. With the rise of mass customization of products — made possible by additive manufacturing, or 3D printing — simulation helps ensure that the finished product has the optimal shape and is made accurately, cost-effectively and with a high degree of consistency over time.

Additive manufacturing might enable us to produce almost any imaginable shape, but which is optimal? Can the human mind even conceive of the optimal shape? And, with mass customization, how do we ensure that every variation still preserves product integrity and performance? Simulation is key to unlocking the potential of 3D printing on a large scale by making it easy for companies to analyze on-demand and answer these questions to deliver unique, reliable, high-quality products with an extraordinary degree of confidence.

As the product moves from design and manufacturing into operations, simulation can continue to play a pivotal role in delivering the best possible results in the field. By using remote sensors to gather data on a product’s working conditions, analysts create a virtual replica — a digital twin — of that product and then apply the same physical forces and other environmental conditions to the digital model. Applying simulation as part of a digital twin can provide vital insights in the form of virtual sensors, in situations where no physical sensor exists or would even be possible. Simulation also can run what-if studies for optimal performance, and can predict critical failure or maintenance requirements.

Digital twins are in their infancy today, but as Industry 4.0 matures, they will become increasingly commonplace, running on demand either in the cloud or on the asset itself. Increasingly, simulation will become an in-product experience in which the digital twin is an inherent part of the product’s design and operation, working alongside artificial intelligence and machine learning algorithms.

"Simulation is being leveraged not just for design validation, but from early ideation through manufacturing, operations and maintenance."

PERVASIVE SIMULATION: THE NEW IMPERATIVE

While not all companies are applying simulation to every product, studying the effects of multiple physics or leveraging simulation throughout the entire product lifecycle, these three trends signal the future. Leaders are already employing these best practices. Soon, leveraging engineering simulation pervasively will no longer be just a competitive advantage of the few, but an absolute imperative for all.

Ongoing improvements in simulation software make it easier than ever for a broad range of users throughout a business to apply these best practices. If you are currently using simulation only in your product development function, or only on certain designs, you are failing to realize the full potential of Ansys software to deliver strategic and financial benefits for your business.

When engineering simulation software made its debut nearly 50 years ago, early adopters quickly distinguished themselves from those companies who were slower to recognize and embrace its potential. Tomorrow, it will be part of the toolbox for every engineer.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.