-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

April 8, 2024

Making a Good Thing Stick: Simulating Contactless Magnetic Gears for Harsh Mission Applications

How do you disrupt an industry so set in its ways that it’s been using the same technology for generations, despite the headaches it causes?

That was the question facing Texas-based FluxWorks. The young company — a spinoff from the Advanced Electrical Machines and Power Electronics Lab at Texas A&M University — aims to break the electric machine powertrain market of its long-held mechanical gear habit. To accomplish that goal, it’s working to commercialize contactless magnetic gears for use in harsh mission applications from the ocean floor to outer space.

FluxWorks is targeting industrial, commercial, and national security clients. It has already partnered with renewable energy businesses and received funding from NASA to investigate solutions for space exploration vehicles. Because FluxWorks’ technology is even capable of transmitting torque through thin air and across solid boundaries, it has potential for use in medical settings and clean rooms.

To define what FluxWorks chief scientist Dr. Matthew Johnson calls “the realm of what’s possible,” the company relies on products accessed through the Ansys Startup Program, an initiative in which qualifying businesses can get multiphysics software bundled with high-performance computing. Specifically, FluxWorks uses Ansys Maxwell in Ansys Electronics Desktop (AEDT) for the magnetic design of their gears and Ansys Mechanical to ensure that their gears are structurally sound and capable of supporting the intense forces and torques resulting from the interactions between magnets.

Johnson, who has worked on magnetic gear technology for more than a decade, credits Ansys with helping FluxWorks turn research into real-world products.

“The startup program has provided us access to Ansys' unmatched suite of modeling software, in particular Ansys Maxwell, which is the backbone of our custom modeling and simulation infrastructure,” Johnson said. “Ansys is supporting our ability to rapidly commercialize magnetic gearing technology.”

Turning Things Around

Whether a gear is mechanical or magnetic, it has the same purpose: to transfer rotation and mechanical power while scaling up or down torques and speeds.

After that, things begin to diverge.

Where mechanical gears use “teeth,” magnetic gears use modulated magnetic fields to exert force without touching, which can significantly extend lifetime and range.

Mechanical gears are prone to performance and maintenance issues that magnetic gears avoid. Among other things, the interlocking parts of a mechanical gear can shear and damage one another. Mechanical gears also tend to be noisy during operation and are susceptible to fatigue failure from excessive vibration. They also require frequent lubrication, and if there’s too much torque — which is especially needed in a big machine operating at low speed — it can cause a total breakdown. And while repairing or replacing a mechanical gear in a ground-level facility may not be that tricky, imagine what happens when one goes bad in, say, a wind or wave turbine. Access alone is expensive and risky.

By contrast, contactless magnetic gearboxes don’t have parts that can bump into each other. Instead, they simply slide past one another, meaning they inherently offer the prospect of higher reliability. They don’t require lubrication, either, or the downtime that comes with it.

Magnetic gearboxes are also potentially acoustically quieter because they don’t have mechanical teeth contacting each other. The FluxWorks team is also working to demonstrate that their gears can reliably withstand long periods of vibration. They’ve already verified that their gears are capable of achieving efficiencies in excess of 99%.

Despite the drawbacks of mechanical gears, until now, countless industries have depended on them almost exclusively. That’s not for lack of alternatives: Patents for early magnetic prototypes go back as far as the turn of the 20th century. Granted, these inventions were equipped with the rough equivalent of today’s refrigerator magnets, but they were out there.

Lately, though, the cold shoulder seems to be thawing. While magnetic gears are still not widely used, they are gaining favor among visionary companies and organizations, which is creating a significant opportunity for FluxWorks’ technology. Johnson thinks the increased interest comes down to twin factors. One is the development of rare earth magnets — chiefly neodymium and samarium-cobalt — that are more powerful than anything that preceded them, but one major downside is their high price point. The other is the increase in computing power that enables designers to improve magnetic gear performance while keeping material usage and costs in line.

That doesn’t always mean reducing the total number of magnets in the design, however. For example, wind turbines — big machines that turn at slow speed — require a lot of magnets to achieve the right amount of torque. Simulations in Maxwell helped FluxWorks look at different grades of magnets and study electromagnetic losses and gains to come up with configurations that would lead to a more efficient way to transmit the necessary torque. One potential solution includes using magnets in more places through the introduction of FluxWorks’ magnetic gearboxes but significantly less magnet material in the generator. This will yield an overall system-level design that uses less magnet material than conventional direct drive generators.

Developing the same design experimentally would have taken considerably longer, Johnson says, and it would have been much more expensive.

“If we had to optimize designs exclusively through experimental methods, it would take an eternity and a huge amount of money,” Johnson says. “Experimental work is still critical, but Ansys simulations allow us to rapidly and cost-effectively evaluate a plethora of virtual or digital designs to dramatically narrow the design space and quickly converge to an optimal solution.”

What’s more, he says, “Simulation lets us work around the clock, even when we’re not at our desks.”

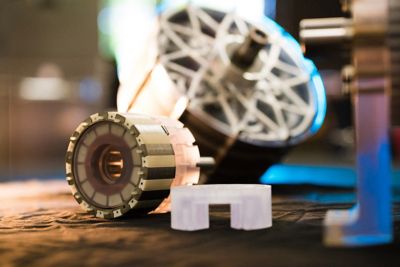

Considering that powertrain designers will likely put FluxWorks’ technology to use in extreme environments and under widely varying operating conditions, the company’s engineers have also modeled how temperature and the threat of demagnetization affect materials and reliability. Simulations have also helped FluxWorks shrink the weight and footprint of their technology, enabling them to scale from palm size to 4 feet across.

“Hypothetically, we could develop efficient and reliable technology for wind turbines so large you could walk through the shaft of them,” says FluxWorks CEO Dr. Bryton Praslicka.

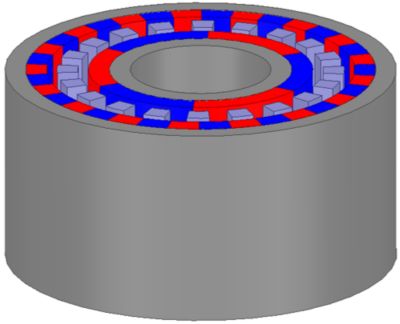

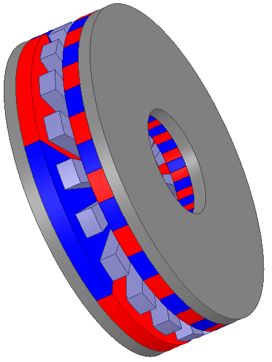

3D models of a radial flux coaxial magnetic gear in Ansys Maxwell.

Experience Matters

While having access to the full suite of Ansys products is giving FluxWorks engineers an edge, Johnson and Praslicka aren’t exactly newcomers to some of the software.

When Praslicka was a doctoral student and Johnson a researcher with the U.S. Army CCDC Army Research Laboratory, they participated in a NASA-sponsored research project on lunar robots. The study, which optimized design trends for a surface permanent magnet (SPM) cycloidal magnetic gear with practical fabrication considerations, enabled the pair and their colleagues to use Maxwell for electromagnetic design and analysis simulations.

Most of the existing literature on magnetic gears concerns coaxial magnetic gearboxes, which have input and output shafts on the same axis of rotation and perform best at gear ratios typically less than 10:1. That means the output gear completes one revolution when the input gear completes 10.

The problem is that the type of electrical machine powertrains NASA is interested in for electric aviation propulsion, aerospace, robotics, and space applications require high torques at high gear ratios. The gear ratios of cycloidal gearboxes can be as great as 100:1. Cycloidal gearboxes are also capable of transmitting high torques.

The Maxwell simulations provided insight into designing magnetic gears that provide maximum specific torque (torque per unit mass) considering a number of design variables: gear ratio, magnetic pole count, geometric dimensions such as outer radius and magnet thickness, and whether the gearbox had an air core or iron core design.

The research resulted in an experimental proof of concept prototype.

In another study also supported in part by the U.S. Army CCDC Army Research Laboratory, Johnson and Praslicka used Maxwell to model the effect of temperature and gear ratio on the achievable specific torque and determine the optimal magnet materials to use in each of a wide range of design scenarios.

Even with their experience, though, Johnson and Praslicka say they’re glad to have the comprehensive support Ansys provides.

“We are extremely thankful for the access to the software licenses and for the access to training resources,” Johnson says.

Geared for Tomorrow

In just one year, FluxWorks grew from two people to 14. The company has attracted clients like NASA who appreciate its agility, the performance potential of its solutions, and the ability of its engineers to leverage modeling capabilities to meet rigorous technical specifications.

“When a client comes to us and says they need to be able to handle a certain amount of torque at a specific temperature range, we can run design studies that let them see how materials, temperature, and other factors influence size, shape, and weight,” Johnson says. “Depending upon what the client is most interested in, we can take that input and simulate results so they can make an informed decision about the design target.”

FluxWorks has no plans to give up its bespoke work with early adopters and high-tech companies, but it also hopes eventually to go more mainstream, offering an off-the-shelf solution that will attract electric machine manufacturers who have been resistant to change.

That will be the ultimate disruption.

Learn more about Ansys Maxwell.