-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

May 9, 2019

Engineers Reduce Torque Ripple in a Switched Reluctance Motor for Electric Vehicles

Switched reluctance motors (SRMs) can be an electrification solution for the transportation, agriculture, mining, civil and tactical sectors. SRMs are a great motor option for electric vehicles because of their low costs, high efficiency and ability to operate in harsh environments.

One challenge that has held SRMs back is that they are susceptible to torque ripple, which causes noise and reduces the motor’s lifespan.

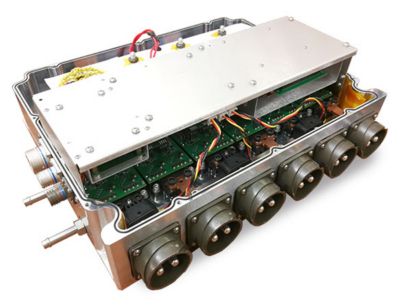

A 100 kW SRM MILSPEC controller with Torque Ripple Mitigation technology, created by Continuous Solutions.

To address this challenge, Continuous Solutions, an Ansys Startup Program member, used Ansys Maxwell to optimize the motor’s control algorithms. The optimizations led to a 90% reduction in torque ripple and a 50% reduction in noise.

What Causes Torque Ripple in SRMs?

To control and understand torque ripple, Continuous Solutions needed to determine how its designs affect the conditions that produce it.

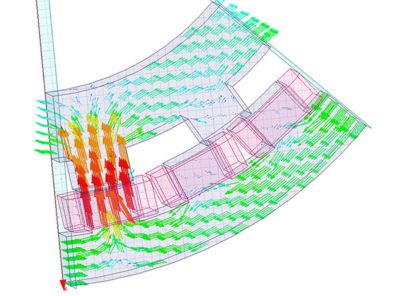

Magnetic flux simulation on the cross section of the rotor

SRMs take advantage of the ability of low-reluctance materials, like iron and steel, to align with magnetic fields. The SRM has phased windings on the stator and a rotor that comprises regions of low and high reluctance.

When power is sent to the stator windings the magnetic flux and reluctance of the materials generate a force to align the rotor pole with the nearest stator pole. The SRM control algorithms turn stator windings on and off successively to shift the magnetic field, forcing the rotor to rotate.

The challenge is that this process also creates vibration and noise due to structural deformations and magnetic torque harmonics that force the stator and rotor to interact. The interactions and vibrations that change the torque — hence torque ripple — create noise and limit the motor’s lifespan.

How to Design SRMs with Reduced Torque Ripple

Continuous Solutions’ aimed to create an SRM that was less expensive and more reliable. This meant it couldn’t increase the motor’s life by making all the parts beefier, as this would increase costs.

Instead, Continuous Solutions created a new control algorithm that could operate the SRM without torque ripple. If the motor is about to jerk in one direction, due to torque ripple, the new control algorithm will inject a signal to the motor to create a magnetic field that cancels out this jerky motion.

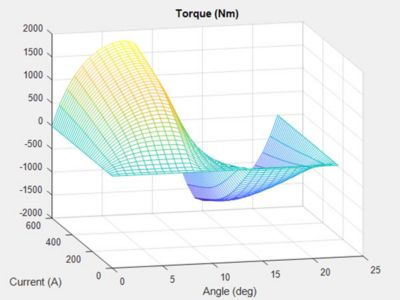

A 3D map that shows the relationship between an SRM’s torque as a function of its current load and rotor position

As a result, Continuous Solutions was able to reduce torque ripple by 90% and noise by 50%.