-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

March 3, 2023

Optimizing the Interior Automotive Lighting Experience

When we talk about optimizing interior lighting for human perception, we’re really talking about two focus areas: safety and driver experience. When interior lighting is designed for the best possible experience, drivers are better equipped to face challenging or unexpected driving conditions and experience less fatigue. Aside from its functional benefits, interior lighting can make a vehicle sleek, modern, relaxing, or simply just cool. Today, lighting has a central role in vehicle styling. (Ever heard someone say, “Light is the new chrome?”)

Automotive interior lighting encompasses satellite navigation/GPS, overhead, storage, reading, and ambient lighting — like light guides or light pipes. Each of these lighting types has a role in driver comfort and safety. Engineers need to balance optics requirements, like homogeneity, with other core specifications related to performance and cost. With the help of multiphysics simulation, engineers can account for the complexity of human-centered design while adhering to core engineering design constraints.

Design Considerations for Ambient Lighting

Engineers face many optical challenges in the pursuit of the best possible lighting configurations and material choices for their vehicle designs. The following factors have a strong influence over the driver’s experience with ambient lighting in a vehicle.

Light Leakage

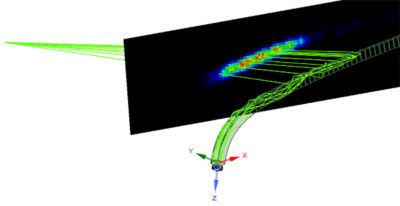

With simulation, engineers can evaluate components like light guides in situ to observe how light behaves (Figure 1). From there, they can identify opportunities to correct defects. Optimizing prisms and interior components improves the light guide itself, but without integrating the guide into the system, it’s impossible to get a realistic understanding of light’s behavior. Performing this kind of analysis earlier in the design process provides more opportunity for cost-conscious corrections.

Figure 1. Tracing rays in the 3D view can help identify light leakage causes.

Colorimetry

Through simulation, engineers can measure color coordinates (Figure 2) in different CIE color spaces to ensure they meet specifications and assess the quality of the lighting source.

Figure 2. Color shift before (top left) and after (bottom left) the RGB modifications with the corresponding CIE 1931 color coordinates (right).

Legibility of a Display

For any given relative visual performance (see ISO 15008:2003), engineers improve readability by implementing displays with as high a resolution (and as low a cost) as possible. Simulation software offers relative visual performance testing to calculate contrast while accounting for character size, background color, foreground color, and distance. Testing helps engineers understand whether text or images are readable for drivers.

Sun Reflections

Performing tests in the dark or in harsh sun offers a more accurate understanding of light source quality because it accounts for riskier conditions. If the driver can’t see the navigational map anymore due to the sun’s reflection, it can be a safety concern. Simulation can help engineers identify critical sun positions when light reaches the driver’s eyes (Figure 3). From there, engineers can measure the unified glare rating to understand where glare could occur and how manageable, or unmanageable, it might be for the driver.

Figure 3. Testing critical sun positions from the driver’s perspective using Ansys Speos.

Design Considerations for Dashboard Veiling Glare

When sunlight hits the dashboard of a vehicle and reflects back at the driver and passengers, they experience glare. By setting a consistent sun position, engineers can run simulations with different leathers and plastics on the dashboard to better understand the level of veiling glare passengers might experience. Engineers can also ensure that decorative chrome elements are stylish and functional without disturbing the driver or creating a potential safety risk at critical sun positions. Many different sun positions can be evaluated for one given trim material.

Effect of Polarized Sunglasses

Many displays use polarized light, so when someone in the vehicle dawns polarized sunglasses, it could impede their ability to read the display. Beyond exploring polarization on the inside of the vehicle, manufacturers turn to simulation to test polarization coatings for windshields. These coatings reflect the rays they don’t want to enter the vehicle.

Luminance

Simulating light quantities like irradiance or intensity is important when designing a vehicle, but the light perceived by the human eye matters most. Simulating luminance is critical for measuring the amount of light that reaches a given point. In Figure 3, for example, that point is the driver’s eye position. Engineers can take it a step further by displaying luminance alongside what the human eye would perceive based on parameters like reaction time, eye conditions, and eye age. For example, perceived glare effect is different depending on the age of the observer. In addition to testing against regulations or measurable specifications, simulating for human vision enables engineers to experience the product virtually, as if it were in front of them (Figure 4).

Figure 4. Tail lamp simulation results from Ansys Speos.

Designing for the Future

As technology continues to develop, interior lighting technologies like head-up displays (HUD) can play an important role in helping drivers and passengers become more comfortable with autonomous functions. Head-up displays provide feedback using environmental detection and openly display the information that the vehicle’s sensors are perceiving. This kind of transparency can have a trust-building effect for drivers. Some manufacturers are working to build trust with pedestrians, too, by projecting symbols like marked crosswalks when an autonomous vehicle has come to a stop.

For more information about Ansys’ simulation tools and workflows for automotive lighting and lighting optimization, see our webinar Real-time Optical Simulation for Reliable and Innovative Automotive Lighting Designs.