-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

March 4, 2024

Monash Motorsport Tops FSAE World Rankings with Support from Ansys

The Monash Motorsport student racing team has topped the world’s Formula SAE rankings for both its combustion and electric vehicle designs. Learn how Ansys fuels its success.

Recently, some impressive student teams from around the world have leveraged Ansys software in their engineering efforts. One of those student teams is Monash Motorsport, composed of undergraduates at Monash University in Melbourne, Australia. The team designs, manufactures, tests, and races its Formula-style cars in both FSAE Australasia FSAE Australasia (FSAE-A) and European Formula Student competitions.

Founded in 2000, the team has achieved some incredible results — including being ranked first in the world for its retired combustion design, as well as being ranked eighth in the world for its electric car design. At the December 2023 FSAE-A competition in Melbourne, Monash Motorsport made history by successfully demonstrating Australia’s first competition-ready driverless car.

Left: The Monash Motorsport team is composed of over 100 students from a range of disciplines, including engineering, science, design, business, and law. Right: Monash Motorsport’s electric car design is currently ranked eighth among Formula Student teams worldwide.

For over 20 years, the Monash Motorsport team has used Ansys Fluent, a simulation tool accessed for free through the help of an Ansys Student Team Partnership, to continuously improve the aerodynamic performance of its car designs. According to Nathan Betros, that support has been crucial to the team’s track record of success. After serving as aerodynamics manager for the team in 2023, this year Betros is leading the team as chief executive officer.

“Since Monash Motorsport was founded, aerodynamics optimization has been absolutely essential to our winning results,” says Betros. “Formula Student tracks are really tight and twisty, and cornering performance is crucial. A Formula One race car generally sees between two and five degrees of steer. In contrast, we can see up to 12 degrees of steer. So, our car is cornering at way tighter angles than what you typically see in professional Formula One racing.

“We add aerodynamic devices like wings to the car to generate downforce and increase traction during cornering,” Betros continues. “We also refine the shape of the undertray to create downforce. But in making those types of changes, we also need to measure and minimize the drag they create on the overall car design, particularly during straight-line acceleration events. Ansys Fluent has always helped our team understand the trade-offs and make intelligent choices that add up to a winning overall car design.”

The M23 car features an improved aerodynamics and vehicle dynamics package to optimize performance through increased downforce and better handling.

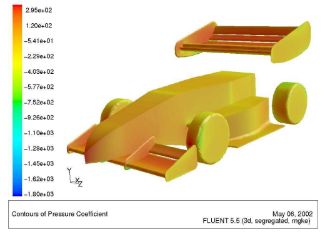

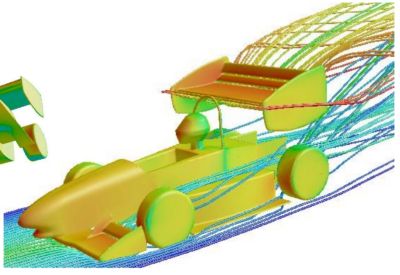

Betros is proud to point out the team’s first full-car simulation using Fluent, created in 2002. Fondly called “Old Faithful” by the Monash team, the simulation took up to two weeks to run on a personal computer. “It’s really inspiring to see how far we’ve come in terms of not only the sophistication of our simulations, but also the computing power we have access to. We’re very thankful that our simulations no longer take two weeks to come together,” he laughs. “But the one constant is that Ansys Fluent has been there for us at every step.”

These historic images from the early 2000s — including “Old Faithful,” the team’s first full-car simulation — demonstrate the length of the Ansys-Monash Motorsport partnership.

Maximizing CLA via Fluent Translates into Big Points

According to Betros, Monash Motorsport has achieved its high global rankings via a single-minded strategy. “When we’re designing a Formula Student vehicle, from Monash Motorsport’s end, we’re always thinking in terms of, ‘How many points is this going to net us at competition?’” says Betros. “From our Fluent simulations, we’ve found that the CLA — which is the lift coefficient multiplied by area — is the third-most sensitive parameter on our car. The more we can increase our CLA, that directly translates to lots of points in competition.

“Ansys Fluent is the perfect solution for simulating our car’s aerodynamic performance and making design changes that maximize the CLA,” he says. “You can come up with some great ideas, but there’s often no way to manufacture them or install them on the car in real life. Fluent allows us to be creative and innovative, but also grounded in real-world physics.”

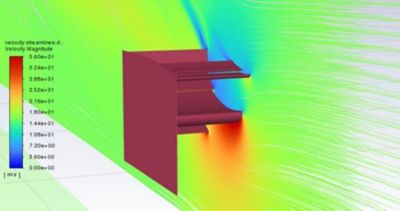

While the team spent many years focusing on bolt-on wings and other very specific design features that maximize the CLA, today’s advancements in computational fluid dynamics (CFD) enable the team to optimize the entire car design for CLA and other aerodynamics characteristics.

“We’ve come to a stage where aerodynamics is considered in the very essence of the vehicle concept,” Betros says. “The advances in Fluent enable us to change part of the chassis, or the shape of the car’s underside, and immediately answer the question, ‘How does this affect our overall aero performance?’”

Nathan Betros conducts an aerodynamics study using Ansys Fluent.

Fast, Full-vehicle Studies Support Design Innovation

The team’s CFD workflow begins with part designers creating a full-car geometry in CAD, which is then meshed and solved in Fluent via an automated process.

“Fluent’s meshing has improved to the point where we can easily change the attitude of the mesh to simulate a very specific degree of cornering,” says Betros. “We can see the extent to which the wheels turn, the degree to which the vehicle pitches under braking, the potential for a rollover — we’re able to investigate all those aspects. And that means we can get a really accurate picture of how our entire vehicle responds aerodynamically to different behavior changes, whether it’s cornering, braking, or another maneuver.

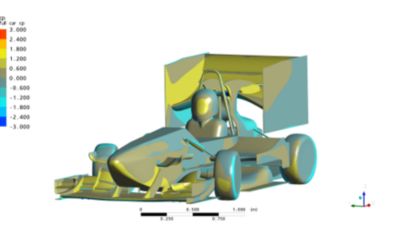

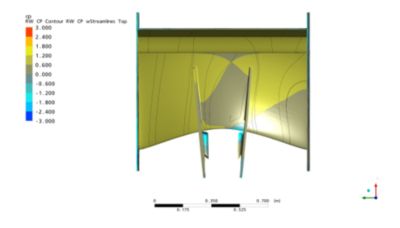

Left: This post-processed computational fluid dynamics (CFD) image shows the pressure coefficient distribution (Cp) across an entire vehicle. Right: This post-processed CFD image shows contours of pressure coefficient across a rear wing.

“Without making any changes to the underlying CAD, we can quickly see the impact of any design update without placing a massive load on our part designers,” he says. “We’re really lucky to have access to the university’s high-performance computing assets, and that gives us around an 11-hour run and post-processing time. For a CFD simulation of a full vehicle, composed of up to 33 million cells, that’s actually quite good.

“We’re able to spend half a day working out our geometry, and then half a day simulating, and we can get our results back in a really quick turnaround,” Betros continues. “And it means we’re able to really compress our aerodynamic design periods.”

Betros is impressed at both the depth and accuracy of the team’s Fluent simulations. “Even though we’re working quickly, we’re not cutting corners,” he says. “We can replicate just about every aspect of the car’s racing performance, from rotating wheels to ground effects and wake, modeled via a k-epsilon turbulence model.” The team has continuously verified the accuracy of its Fluent studies via physical tests in Monash University’s wind tunnel.

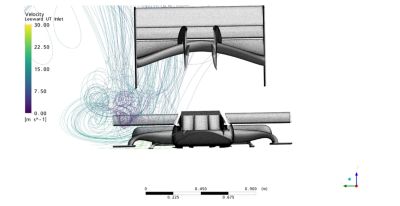

Left: Streamlines show how the undertray flow affects the rear wing flow attachment. Right: As part of their Junior Projects, Monash Mptorsports’ newest aerodynamicists create an optimized rear wing profile using Fluent.

Ansys and Monash: A Winning Formula

“Monash Motorsport was one of the really early Formula Student teams to implement aerodynamics studies of its car,” Betros says, “and I think that’s made a huge impact on our ability to continuously innovate and achieve top worldwide rankings.”

What’s next for the Monash team? “Looking ahead, we’re going to investigate how powered aerodynamic systems, like blown diffusers and motor-cooling systems, might take our car’s performance to an even higher level,” states Betros. “Whatever direction we decide on, Ansys Fluent will play a central role in our development efforts. We’re grateful to have access to an industry-standard tool as undergraduate engineering students — and it’s an opportunity we make the most of, every day.”

Learn more about an Ansys Student Team Partnership to give your team a competitive edge in the next competition.