Motor drives control speed by converting alternating current (AC) power at line frequency into variable frequency and variable amplitude AC power. Motor drives have become critical for industrial applications due to the need for automation, higher process efficiency, and higher reliability. These requirements, in turn, impose development challenges during the design of power electronics components for motor drives. However, simulation can now aid in developing these components and unlock the next-gen potential of industrial motor drives.

Motor drives can be classified as medium voltage (MV) or low voltage (LV) depending on the motor voltage rating. MV drives are used for applications higher than 1 kilovolt (kV). Both types of drives are used in industrial equipment to operate pumps, compressors, fans, and conveyors, with applications ranging from power generation and mining to chemical and metals processing.

Innomotics, a leading supplier of motor and large-drive systems with headquarters in Germany and locations around the world, is upgrading its MV drives with artificial intelligence (AI) capabilities using Ansys multiphysics simulation and digital twin technology. The AI capabilities will improve drive performance with more awareness of the real environment, pushing past design limitations, the company says.

By integrating Ansys mechanical, fluids, and electronics simulation, as well as digital twin solutions, Innomotics embraces digital engineering through techniques like reduced-order modeling, which simplifies complex models without sacrificing accuracy. In addition, virtual testing and prototyping minimize the time and cost of traditional physical methods. As a result, the international supplier optimizes and advances design, cuts costs, and accelerates development.

Medium voltage (MV) drives control motor speed in industrial equipment like compressors, pumps, and fans in industries from power generation and mining to chemical and metals processing.

Evolving With Digital Engineering

Although all MV drives control motor speed by providing variable AC power, there are two main types depending on the output — current source inverters (CSIs), which have a controllable current output, and voltage source inverters (VSIs), which have a controllable voltage.

Innomotics offers both types and designs MV drives with a range of voltages between 1.4 and 13.8 kV and power ratings from 150 kilowatts (kW) to 85 megawatts (MW). This ensures high efficiency, high availability, and exceptional energy quality, reducing the current distortion at the input, according to the company. In fact, Innomotics’ VSI drives are considered clean energy converters, causing minimal harmonics. This has inspired the “Perfect Harmony” product name for some models.

The MV drives featured in this article convert MV power at available, fixed amplitude and frequency — 50 or 60 Hz — to an intermediary direct current (DC) voltage and then back to AC power of variable amplitude and frequency. Thus, the speed and power of the electric machine can be conveniently adapted to the customer’s application.

Dr. Bogdan C. Ionescu, a senior principal key expert in the Power Electronics group at Innomotics, has seen digital engineering evolve at the company over the past decade. Innomotics, which was formerly part of Siemens AG, was acquired by KPS Capital Partners LP in October.

Dr. Ionescu works on key development issues in the research and development (R&D) department in the company’s Large Drives division.

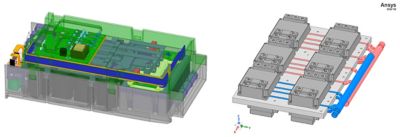

The Innomotics Perfect Harmony GH 180 MV drive is a multicell voltage source inverter (VSI) with modular multilevel converter (M2C) technology.

“For the past 12 years, the penetration of digital technology in the Power Electronics group only increased to the point where we have created digital models of power cells and power transformers, which are the main building blocks of our MV VSI drives,” he says. “Many other designs at the component and product level were also successfully tackled.”

By integrating Ansys simulation, Dr. Ionescu says his team improves the design process while saving time and money. What’s more, they know they can trust the results.

“All this simulation technology made possible by using Ansys simulation software has a huge impact in avoiding costly design mistakes,” he says. “It is noteworthy that all our simulation results have been verified through extensive laboratory testing and are now highly trusted by management. The orientation to invest in simulation technology was proven to be correct and beneficial for the bottom line of the company.”

Diving deeper into the benefits of simulation, for the past seven years Dr. Ionescu and his team have developed reduced-order models (ROMs) for many of the company’s air- and water-cooled components to test future concepts, including in hardware-in-the-loop (HIL) systems.

His interest led to further research and a paper in IEEE about ROMs and how they can enhance MV drive design with capabilities like implementing accurate thermal models in real time, which supports the development of AI-capable drives.

Although the Innomotics’ AI-capable MV drive is still under development, Dr. Ionescu says the company has patented the concept.

Applying Simulation, ROMs, and Digital Twins

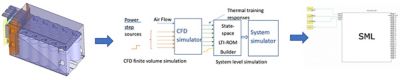

Dr. Ionescu and fellow engineers create ROMs and digital twins using the Ansys Twin Builder simulation-based digital twin platform. Twin Builder software couples with Ansys’ multiphysics solutions to deliver the behavior of 3D simulations as ROMs to generate accurate and efficient system-level models more quickly. For example, the platform can use ROMs produced from Ansys’ structural, fluids, and electromagnetics products to model complex systems, including mechanical assemblies, thermal networks, and electromagnetic actuators and machines.

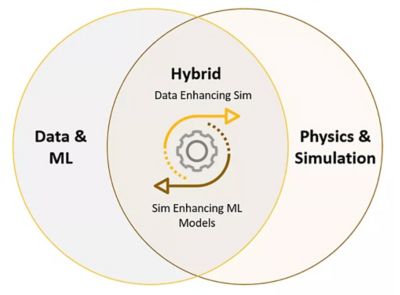

Ansys’ latest digital twin solution, Ansys Twin AI AI-powered digital twin software, works in a similar fashion, leveraging ROMs while blending data and physics to create what Ansys calls hybrid digital twins. Ansys’ hybrid analytics tools bridge the gap between design and operations by combining insights from simulation with data from field behavior, considering changes in operating conditions and equipment degradation. As a result, hybrid digital twins enable real-time monitoring, predictive maintenance, and performance optimization across operating scenarios and product variations, automatically adapting to changing environments, circumstances, and conditions. One can create hybrid digital twins using either Twin Builder or TwinAI software. ROMs can also be created in the Ansys Workbench simulation integration platform and easily imported into Twin Builder or TwinAI software. For added convenience, the ROMs are available in a number of popular formats, including service modeling language (SML) and functional mock-up unit (FMU).

Ansys hybrid digital twins combine data, physics, and artificial intelligence/machine learning (AI/ML) techniques to provide the most accurate representation of an asset.

Dr. Ionescu and his team create ROMs mainly to optimize the thermal utilization of the thermal components of the overall application, he says.

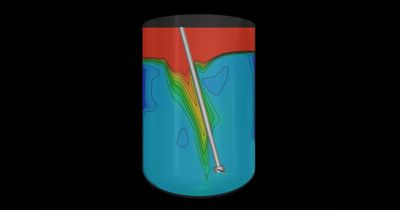

Innomotics uses Ansys simulation tools to generate thermal training data and create reduced-order models (ROMs) for accurate and fast representation of the physics within power cells.

“Ansys ROM techniques — linear time-invariant (LTI) and linear parameter varying (LPV) — are used to serve the purpose of creating a digital twin,” he says. “This digital twin at its turn can execute very quickly and thus provide a number of quantities of interest, such as the internal temperatures of the insulated-gate bipolar transistors (IGBTs) used within the power cells. Note that such temperatures cannot be measured directly. Thus, the digital twin can provide these needed results in real time or quasi-real time to be used by the drives controller.”

In addition, the team uses Ansys Icepak electronics cooling simulation software for computational fluid dynamics (CFD) simulations to improve the accuracy and quality of training data for the ROM.

Innomotics engineers use Ansys simulation software to model the Innomotics Perfect Harmony GH 180 MV power cells both air-cooled (left) and water-cooled (right).

“A future step in the development of the AI-capable drive will be machine learning (ML) ability,” he says. “Such efforts will benefit from the ability of the ROMs to produce such large amounts of data offline for training the machine into developing useful patterns of changing the way the drive responds to different challenges of the customer processes.”

Dr. Ionescu’s team uses Ansys simulation daily. As results are consistently verified through lab tests, trust and adoption of simulation has increased across the organization.

“In the process, we use a large number of Ansys tools covering the entire spectrum of physics of interest for our applications,” he says. “This means that we use Ansys for a multitude of mechanical, electromagnetic, CFD, and system-level simulations. Additionally, we use Ansys for a vast diversity of coupled multiphysics simulations by combining the various Ansys modules within the framework provided by the Ansys Workbench environment. This was a huge reason for selecting Ansys years ago as the simulation system of choice, based on our deep understanding of Ansys philosophy of software development and acquisitions. It is clear today that it was the right choice for us.”

Developing Next-gen Drives

Dr. Ionescu expects that industrial customers will benefit from AI-capable MV drives with greater engineering insights into challenges such as thermal, overload, and airflow rate management.

“One clear advantage of AI in the operation of the drives is to considerably reduce the limits imposed by the design margins,” he says. “In other words, the safe design approach currently used due to various unknowns in the process can be greatly diminished or perhaps eliminated since the drive now has all the data it needs to know regarding those unknown aspects.”

In addition, Ansys simulation, digital twin technology, and techniques like reduced-order modeling help Innomotics improve design and minimize costs while speeding up development without compromising accuracy. Digital engineering empowers Innomotics to embrace virtual testing and prototyping, which results in time and cost savings.

“The use of Ansys simulation technology for the company has been huge in my opinion,” he says. “It has even helped optimize our workforce, (as it is) capable of producing critical answers in a fast and safe manner. It also brings huge contributions by reducing unnecessary testing in the labs and allows digital prototyping, as well as participation in HIL and software-in-the-loop (SIL) sophisticated and cost-effective systems.”

To learn more about how digital twins and ROMs can improve your workflow, watch the free on-demand webinars “Boost Simulation With Reduced-order Models Using Ansys Twin Builder” and “Ansys TwinAI: Combining Physics Accuracy With Data-driven Insights.”

To explore Ansys digital twin solutions firsthand, request a free trial.

Just for you. We have some additional resources you may enjoy.

“All this simulation technology made possible by using Ansys simulation software has a huge impact in avoiding costly design mistakes. It is noteworthy that all our simulation results have been verified through extensive laboratory testing and are now highly trusted by management.”

— Dr. Bogdan C. Ionescu, senior principal key expert in the Power Electronics group, Innomotics