-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

By 2030, the International Energy Agency (IEA) expects electric vehicles to represent 60% of all new vehicles sold globally, according to its 2050 roadmap to net zero for the global energy sector. According to the IEA, which works with governments and industry on sustainability initiatives, nearly 1 in 5 cars sold in 2023 was electric. That’s 40 million on the road currently: 60% of which are in China, just under 25% in Europe, and 10% in the United States. Overall, sales remain limited. Most carmakers will need to accelerate development if they want to meet industry targets. However, a lack of design and manufacturing competency poses significant challenges.

In the current environment, consumer demand for internal combustion engine (ICE) technology remains strong. This puts original equipment manufacturers (OEMs) in the precarious position of balancing novel EV technology development with that of existing, tried-and-true ICE vehicle programs.

Strictly EV manufacturers do not experience these dynamics in quite the same way. They are able to start fresh and innovate very rapidly without the baggage of maintaining existing business because they don't have to divide their resources across technology platforms. Many are making faster progress without having to divert time and resources away from electrification to support existing vehicle programs.

To keep up with this accelerated pace, OEMs must shift left, or move tasks, processes, and responsibilities earlier in the design workflow to simultaneously engage in new product development and new technology introduction.

“How can OEMs navigate the complexity of delivering on a 100-plus-year ICE business model and advance their electrification objectives to remain competitive?” asks Tushar Sambharam, senior principal application engineer at Ansys. “It requires them to step away from familiar ways of doing things to successfully develop EV technologies and implement them at the same time.”

The next frontier in accelerating EV product development brings the ability to use virtual plant models and actual controller algorithms to perform early-stage requirement verification in a simulation environment. The frontloading of virtual integration, testing, and validation of critical performance metrics, including range, power, and acceleration, necessitates the fast and accurate plant models required for system-level studies.

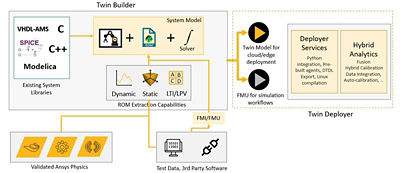

Let’s explore how the Ansys Twin Builder simulation-based digital twin platform can be used for virtual validation and help speed EV technology to market that satisfies automotive manufacturing requirements.

Connecting requirements for an ASIL D-qualified physics-based battery simulation

Virtual Models Pave the Way for Early-Stage Verification

A siloed approach to vehicle software and hardware development is generally the default for OEMs in a traditional design workflow. Many times, the confluence of both occurs either during hardware-in-the-loop (HiL) (software system) bench testing or as part of an actual vehicle assembly. This process, although somewhat efficient, is not without risk, as any issues encountered at this stage could possibly set a program back seven or eight months to refine any architectural issues.

This is where early-stage verification via simulation is important, as it offers greater flexibility to make changes dynamically without committing any costs. Most often, however, this approach considers specific, physics-based challenges in isolation. Rather than focusing on a single discipline, a digital twin incorporates several multiphysics tools and solvers to model an entire system. This enables engineers to examine entire collections of components or vehicle systems subject to all system dynamics concurrently, such as fluid, mechanical, and electromagnetic.

A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. As it is defined here, a “virtual representation” is a set of correlated digital models and supporting data that collectively provide cohesive information about their subject matter. All digital twins have synchronization mechanisms that enable them to mirror real-world entities more closely in a simulation environment.

It's important to note here that there are two types of twins: design and operational. While operational digital twins are connected to and interacting with a working physical asset via sensors, design twins are not, which makes them particularly valuable early in development during the design phase, when the details of a vehicle system or systems are still in flux. With help from Twin Builder software, it’s possible to employ virtual digital design or operational twins to speed development times crucial to EV success.

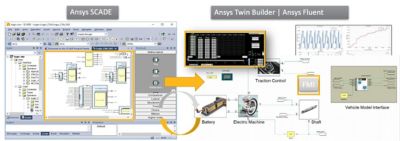

For example, after borrowing various components from an existing platform design, you can build a new vehicle design. With Twin Builder software, it’s possible to put this design into a virtual model of the physical system (also known as a plant model), then integrate control algorithms, or mathematical specifications within the plant model, to test various aspects of that model. You don’t have to wait on a physical prototype to validate vehicle systems in their entirety.

What you have in the deployment of a newly created physical system model is a means for rapid, continuous integration and verification of both software and hardware designs at every stage, with whatever knowledge is available about your product. Using Twin Builder software, an early-stage virtual model can be built, then validated and optimized. From there, the model continues to evolve in both quality and accuracy as it moves through a product development cycle.

Ultimately, this approach gives automakers more confidence in how their EV designs will perform in the field — a welcome element in the pursuit of novel, rapidly evolving technologies. Physics-based plant models can capture component behavior virtually on a system level, reducing the need for extensive (and expensive) iterative testing on the bench.

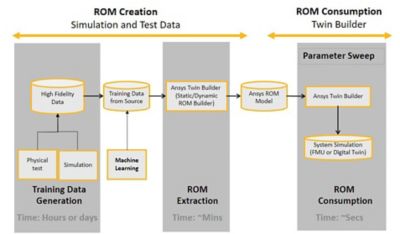

Data- and physics-based reduced-order models (ROMs)

Break It Down to the System Level With Reduced Order Models

As mentioned previously, one of the big benefits of creating a digital twin is the ability it affords engineers to assess designs in consideration of multiple physics. For instance, if you use simulation to build a battery model only from an electrochemical perspective, you may only be able to capture the state of charge (SOC). If you can’t capture the thermal behavior of that battery relative to SOC, you won’t have a clear understanding of how that thermal response is playing out.

What’s needed is a way to extract more information out of that same model. Specifically, physics-based reduced-order models (ROMs) are the means to get you there. Twin Builder software enables the import of ROMs, or streamlined versions of intricate high-fidelity models of physical systems that capture the behavior of the source models in a system simulation environment. Their purpose is to reduce the complexity of the full-order, high-fidelity model you’re working on so that engineers can better study a system’s dominant effects while simplifying the number of computational resources required to do so.

Rather than examining one element of a design, connected ROMs break down that design into multiple physical models and capture the complex interactions between them. This gives you the ability to make real-time predictions — in the context of a digital twin — about the performance of those entities within an entire vehicle system, and it significantly shortens design cycles that lead to higher-quality products.

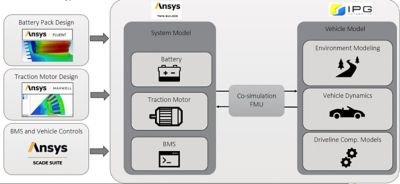

Electric powertrain lends itself well to this approach, as it is a multidisciplinary and hierarchical system with notably complex interactions between software development and hardware design. It is through analysis in a ROM-based environment that incremental, yet significant, efficiency and operational gains can be realized for the entire powertrain.

Ansys Digital Twin software architecture

Harness the Power of Existing Simulation Data To Do More

Today, many of our automotive customers are taking advantage of a large portfolio of Ansys multiphysics solvers to perform computational fluid dynamics (CFD) simulations for battery design, electromagnetic simulations for motor design, and a lot of mechanical simulations, among others. They’re doing all these simulations as part of an entire workflow used to generate very important information to gain a deeper understanding of various aspects of a product.

But what happens to all the data generated in this entire workflow once this initial analysis is over? Typically, it doesn’t flow downstream. It is used to design a component in isolation, then discarded. Using Twin Builder software, you can recycle this information at the system level to understand more complex interactions.

For example, if you take battery information coming out of this workflow and connect it with a battery management system model, it’s possible to do model-in-the-loop (MiL) analysis or model-based testing to see if there is a temperature increase on one of the cells relative to this additional data. From there, you can determine whether the battery management system (BMS) is operating within the required amount of time to disengage that cell and avoid thermal runaway.

ROMs are particularly useful during EV validation as they can be abstracted at various levels to better understand performance through further data analysis.

“For OEMs, analyses like these address big-ticket questions around performance at the vehicle level, like how much range a vehicle delivers, real drive behavior and system efficiency per drive cycle,” Sambharam says. “Abstracting ROMs out onto the vehicle level, OEMs can build a virtual model of a vehicle by taking component models to the subsystem level. Once the subsystem validation is done, the models (and data) can be abstracted out again to do a vehicle-level validation around performance parameters, such as acceleration or range performance, as well as safety.”

Virtual track testing for an electric vehicle

Extend the Simulation Environment To Demystify EV Performance

OEMs can also use Twin Builder software to run all possible test cases in a virtual environment to comprehend vehicle performance. This facilitates an understanding of how many test validations are passing, how many are failing, and why failures occur. Armed with additional insights like these, car manufacturers can then make informed decisions about what designs they can realistically prototype and test.

Once you have all your ROMs, connecting them to open integration platforms via digital twin enables you to extend the simulation environment to analyze vehicle performance in specific driving scenarios. Through this level of data exchange, it’s possible to seamlessly test and validate model performance in all development stages, subject to any number of virtual test scenarios or edge cases — for autonomy, advanced driver-assistance systems (ADAS), powertrain, and vehicle dynamics.

“Essentially, OEMs need a tool that is able to mimic a requirements-based test matrix as much as possible in a virtual environment. And that's where the flexibility and accuracy of Twin Builder software, ROMs, and the ability to handle multiple physics comes into the picture,” Sambharam says. “Integration of these capabilities into third-party driving simulators enables vehicle manufacturers to capture corner cases accounting for all kinds of physics-based interactions, be it mechanical, fluids, or electromagnetic; those between software and hardware; as well as interactions between a vehicle and the driving environment.”

Learn More

Digital twins have been around for a while, yet some OEMs are not taking advantage of how they can advance electrification objectives faster. To learn more, watch Virtual Validation for Accelerated EV Development Using Ansys Twin Builder Software and Digital Twins for Electric Vehicles. You can also download a free trial of Twin Builder software.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.