-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

January 12, 2018

7 Examples of Engineering Simulation Excellence Added to the Ansys Hall of Fame

It always astounds me what our Ansys customers accomplish with our software. Applying Pervasive Engineering Simulation, engineers, designers and students from organizations around the world and across a vast array of industries submitted a large number of innovative entries to be considered for the Ansys Hall of Fame. It was very difficult for our judges to pick the winners among such great examples of engineering excellence.

Here are the winners of the 2018 Ansys Hall of Fame Competition.

Commercial

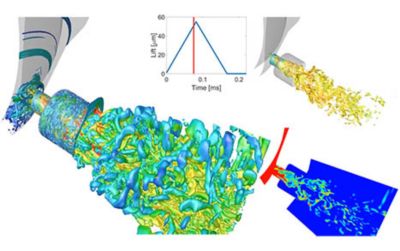

Delphi Technologies presented simulation for fuel injector design and spray performance of gasoline direct injection engines. Improving the design can reduce emissions and impact engine performance over time.

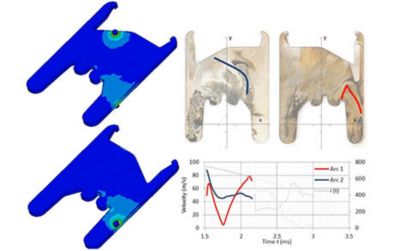

Using structural and electromagnetic simulations to determine the motion of the arc, Lucy Electric engineers optimized the splitter plate arrangement for a switchgear.

To obtain maximum heat flow and reduce the system temperature by 20 percent, engineers at Peraso Technology used Ansys software to determine the optimal enclosure structure and openings for a dongle.

Startup

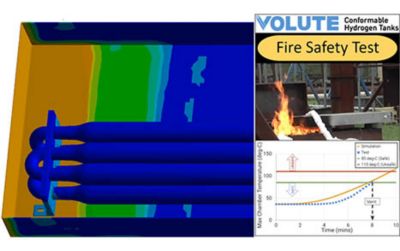

Volute, Inc. engineers created a virtual version of a pressurized hydrogen fuel-cell tank undergoing a fire safety test and used simulation to conduct and pass the test in a cost-effective, safe, and controlled manner.

Academic

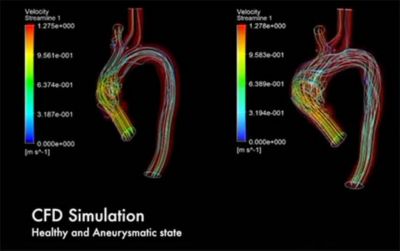

Using Ansys CFD and RBF Morph, researchers from FTGM created a virtual statistical patient to analyze the blood flow and blood pressure alterations for aneurysms.

To determine the effects of heat and pressure on the final shape and performance of a composite ski, researchers from Lucerne University of Applied Sciences and Arts employed structural analysis to perform thermal–transient simulations of the heat press manufacturing process.

To limit NOx emissions for aeroengine combustors demands a careful design of the injection system. Researchers at the University of Florence leveraged Ansys CFD to improve prediction of heat loads and metal temperature.

Get more information on the winners and runners-up at the Ansys Hall of Fame.