-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

September 29, 2021

Culture Clash: The Human Side of AI and the IoT

What happens when you integrate two of today’s most important technological innovations: artificial intelligence and the internet of things? That’s what the AIoT User Group would like to know. The group describes itself as “an open, non-profit organization, which brings together AI and IoT practitioners to exchange experiences, provide guidance and share good practices for the execution and delivery of AIoT-enabled products and solutions.”

To help fulfill that mission, the group has created the AIoT Playbook, which presents a framework for successfully building smart, connected products and solutions with AI and the IoT.

“When we started out, really, it was to get manufacturing and IT, or IT/OT, to work together,” says Dirk Slama, Vice President at Bosch. “There you already have very different cultures. You have the Agile mindset of the software developers and the risk and security control-oriented mindset of manufacturers – and now you’re adding AI to equation. I would say we now even have a clash of three worlds: manufacturing, software and AI, and they all work differently. We need to get them working together.”

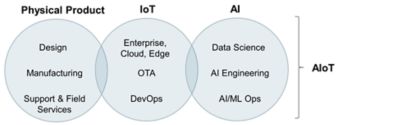

Capabilities required for implementing AIoT include designing, manufacturing and supporting the physical product; IoT capabilities, which usually include over-the-air (OTA) updates of software deployed to assets in the field; as well as the AI side. Credit: aiotplaybook.org, creative commons 4.0

Combat Complexity with Simulation and Digital Twins

Slama, who serves as Editor-in-Chief of the AIoT Playbook, says it is focused on integrating physical products or assets with intelligence in the field (edge AI) and in the cloud (swarm intelligence). Digital twin concepts can be used to help manage costs and complexity.

“Working with physical products in general is expensive – any type of physical test endeavor is expensive,” he says. “This is where simulation makes sense.”

The complexity often stems from working with physical assets, which is different from many normal, purely digital IT projects. To bring AI into the IoT, you need lots of data on how the physical products are behaving in the real world. It is challenging to develop AI for a physical product because you need an environment where you can mature the AI to ensure high-level of accuracy.

“This is also where simulation also comes in,” Slama says, “because before you let your AI-enabled product out into the wild, you can use simulation to go the first part of way – to get a product that has basic functionality. Then even after you leave the simulated space and enter the real world, you can then continue to use simulation to improve the accuracy of the AI for example using virtual sensors in addition to the real physical sensors. Combining virtual and physical sensors can improve the quality and accuracy of the product.”

Digital Twin Example: Battery Management Systems

To help explain the importance of digital twins and simulation to AIoT, Slama interviewed Dr. Prith Banerjee, Chief Technology Officer of Ansys, and Dr. Przemyslaw Gromala, team leader of Modeling and Simulation at Bosch Engineering Battery Management Systems and New Products. Banerjee also serves as a member of the AIoT editorial board.

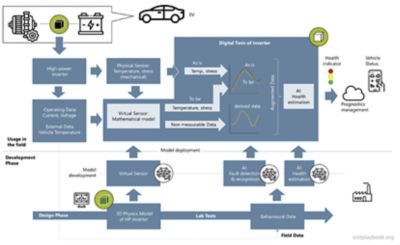

In the AIoT Playbook, Banerjee and Gromala explain how digital twins are being used to inform the design of high-power inverters for electric vehicles, which converts the direct current from the HV-battery into the (3 Phase) alternating current controlling the motor.

It would be impractical and cost prohibitive to use physical sensors to collect all the data you would want from an inverter, so virtual sensors are used in conjunction with physical sensors.

“You can derive a virtual sensor from the physics simulation model,” Banerjee says. “Combining real sensors with virtual sensors can get you a digital twin, which is representing the real world with a very high level of accuracy.”

An example of how a digital twin of a high-power inverter in an electric vehicles uses physics simulation and virtual sensors. Credit: aiotplaybook.org, open source creative commons 4.0

In the AIoT Playbook interview, Gromala says “the combination of nonlinear simulations, virtual sensors, and machine learning is giving us a real edge. This is the foundation for new applications like the estimation of the state of health of the devices, including prognostics and health management for power electronics. And once we have this established, we can then even think about predictive maintenance for electronics systems.”

In addition to the playbook, the AIoT User Group also hosts Unplugged sessions where they come together to work on the AIoT Framework and take deep dives into particular topics. The group also presents training sessions and has a hands-on lab, which is operated by Ferdinand-Steinbeis-Institute at the Research Campus in Heilbronn, Germany, for testing and validating some of the concepts being developed in the AIoT User Group.

For more information, visit the AIoT Playbook and the Ansys Twin Builder page.