By accurately predicting materials properties upfront, engineers in the construction industry can improve energy efficiency, strength, and other performance characteristics.

The global construction industry faces many challenges, including rising costs, growing demand, material shortages, and increasing standards for energy efficiency and thermal performance. Engineers in the industry are focusing on material innovations as the key to addressing these challenges — and with good reason.

While previous generations of construction engineers were constrained by limited material choices, today it’s possible to create new materials from the ground up. That means construction teams can custom-engineer materials for the exact performance characteristics that are required for a specific building envelope. Whether engineers are focused on strength or thermal insulation, today’s advanced technology enables them to specify and accurately predict the performance of a specific materials configuration.

The only problem? This capability is enormously underutilized.

Traditionally there’s been a disconnect between materials scientists and the engineers who design and construct buildings. Ansys is helping to close that gap with a unique suite of solutions that support integrated computational materials engineering (ICME). By numerically modeling materials and assessing their properties at the earliest stage of design, engineers and researchers can create customized building envelopes and material formulations that optimize performance across a range of physical forces, weather conditions, and other operating parameters.

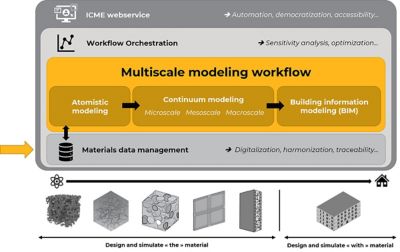

Ansys ICME solutions facilitate seamless multiscale simulation workflows and centralized data management, placing ICME within the reach of every engineering team. While the technology is advanced, it can also be accessible and user-friendly.

The Importance of a Multiscale ICME Approach

ICME holds the promise to optimize materials specification and its impact on building performance, creating a new generation of more energy-efficient, sustainable, and otherwise optimized structures. Today, Ansys solutions are placing this advanced capability within the reach of every construction industry engineering team. One of the key benefits of Ansys software is its ability to model construction materials and their performance across scales.

Ansys enables an end-to-end ICME approach that begins with determining the building’s desired performance characteristics and choosing and designing materials with the help of Ansys Granta MI Enterprise data management software. Built on the foundation of Granta’s trusted reference data, this materials intelligence platform stores, controls, and analyzes materials data, creating a single, accurate source for characterization activity. Engineers can use Granta MI Enterprise software to iteratively select and evaluate material options, working toward the optimal balance of strength, weight, thermal insulation, and other desired properties.

Multiscale materials modeling is driven by using Ansys optiSLang process integration and design optimization software to perform optimization and sensitivity analysis, enabling a streamlined and automated approach to refining the design. Ansys optiSLang software facilitates multidisciplinary process integration and orchestrates simulation workflows, leveraging advanced algorithms to identify the most robust design configurations. This approach also extends to materials selection, providing automated optimization and ensuring efficient exploration of design possibilities.

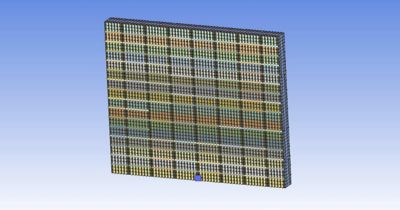

Ansys supports a streamlined multiscale modeling approach that integrates tools like the Material Designer tool for mesoscale analysis, Ansys Mechanical software for structural evaluation, and the Composites PrepPost tool for composite and layered material modeling — all within the Ansys Workbench simulation platform.

Along with partner solutions and third-party codes, materials scientists can use end-to-end solutions from Ansys to facilitate ICME and assess materials contributions and performance across many parameters and weigh trade-offs, and quickly make the best decision for a given building envelope.

iclimabuilt: Demonstrating the Real-world Benefits

Applying Ansys solutions to optimize building materials via ICME isn’t just a theoretical concept. This approach is being used right now by members of iclimabuilt, an open innovation test bed for the global construction industry focused on driving more energy-efficient building envelope designs. With 27 partners in 14 countries, iclimabuilt identifies innovative, advanced practices for building design and construction, then encourages their widespread adoption. Ansys solutions are at the heart of the consortium’s efforts to computationally optimize construction materials via ICME for the desired performance characteristics.

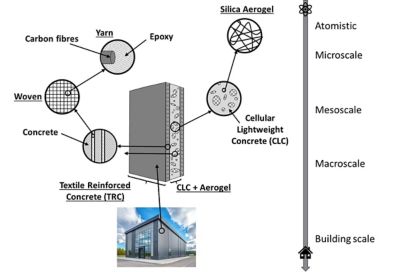

Research funded by iclimabuilt has already identified a new building material configuration — including textile-reinforced concrete, cellular lightweight concrete, and a silica aerogel — with a thermal conductivity that exceeds 0.03 W/(mK). The new configuration was modeled and verified at every scale using Ansys solutions.

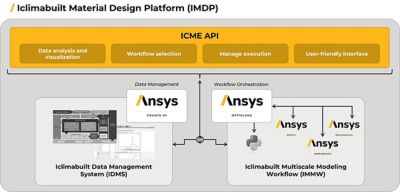

Ansys has created the iclimabuilt Material Design Platform (IMDP), designed specifically for the construction industry, that connects engineers with Ansys solutions via a user-friendly application programming interface (API) that functions as a web service platform.1 Users can execute their material and building design simulations, manage data, and orchestrate workflows through a single portal. They can access the models they’ve already created, run them, customize parameters, and view results for a given materials composition and specific building envelope design.

In this real-world example of how Ansys solutions can be applied to drive ICME, innovative building façade materials (i.e., combining textile-reinforced concrete and cellular lightweight concrete insulation) have been explored to create affordable, mineral-based solutions with enhanced performance. To enable this analysis, a multiscale ICME model was developed in collaboration with iclimabuilt project partners Technological Institute of Aragon (ITA) and Politecnico di Torino (PoliTO).

This modeling approach uses the Workbench platform and enables the virtual construction and evaluation of composite configurations, including “sandwich” materials. The approach is flexible and can be extended upstream to integrate atomistic-scale models developed with tools like the LAMMPS molecular dynamics simulator, if required. Similarly, downstream evaluation of the proposed building's performance using materials from the multiscale model can be conducted with solutions like Autodesk Revit.

While this is just one example of how Ansys software can be applied to facilitate ICME, iclimabuilt’s modeling approach has proven successful because it removes the most common obstacles for engineering teams that want to adopt ICME, including disconnected interdisciplinary tools and processes, complex data management challenges, and the need to bridge materials science and building design.

The iclimabuilt approach saves significant development time and costs by enabling multifunctional engineering teams to iterate on their materials studies and building simulations in a seamless, closed-loop process. It also minimizes physical prototyping costs by accurately predicting “as-built” performance at a very early stage of design. It also spurs much-needed innovation in the global construction industry by enabling engineers to test groundbreaking new materials and building envelopes in a risk-free virtual environment.

iclimabuilt estimates that its Ansys-based platform and modeling approach will result in materials and system performance verification that is 30% faster than previous noncomputational methods. In addition, a physical prototype structure funded by iclimabuilt in Dresden, Germany, has provided real-world evidence that Ansys solutions accurately predict the thermal conductivity of building envelope designs.

While the iclimabuilt Material Design Platform (IMDP) was specifically configured for the global construction industry, it serves as an example of how ICME can be leveraged in an accessible, “one-stop” manner in other industries.

Building a Strong Foundation for the Future

iclimabuilt’s use of a material design platform configured specifically for the construction industry serves as an important proof point for the global engineering industry. By partnering with iclimabuilt, Ansys has demonstrated that ICME produces accurate performance predictions in a time- and cost-effective manner. The iclimabuilt platform also emphasizes the importance of seamlessly linking multiple scales of analysis, multiple engineering functions, and multiple technology solutions for greater accessibility and usability.

The global engineering community is just beginning to discover the significant value that can be achieved by linking materials science with product development via ICME. Ansys is committed to making ICME more widely adopted by educating engineers about the benefits of orchestrated, multiscale materials modeling, as well as providing them with an easy-to-use platform for automating workflows and managing data.

The automation of ICME workflows, coupled with a user-friendly no-code or low-code interface, will democratize access to sophisticated materials modeling tools. This makes it possible for a broader range of nonexpert users to engage with the technology and enable more companies to leverage the benefits of materials customization. iclimabuilt members and other early adopters of ICME are paving the way for greater innovation in materials science, as well as across every engineering discipline, as the contribution of materials is maximized.

Learn more about how Ansys Granta Materials Information Management software can help you get the most out of your materials information.

1. The physics- and industry-agnostic API that connects Ansys solutions to the IMDP was developed and validated by Ansys during another collaborative project, MUSICODE.