In structural engineering, precision and efficiency are not just goals, but also necessities. As projects become increasingly intricate, the ability to streamline workflows while ensuring compliance with industry standards is essential for successful outcomes.

This blog presents five practical strategies to enhance your Ansys workflow using SDC Verifier. By leveraging these techniques, you can optimize your analysis processes, reduce errors, and improve overall project timelines — all critical factors in today’s competitive engineering landscape.

Tip 1: Streamline Model Setup With Automated Recognition Tools

Use Joint, Beam Member, and Weld Recognition To Simplify Model Preparation

Setting up a model for structural analysis requires precise identification and classification of joints, beam members, and welds. SDC Verifier’s Joint Finder, Beam Member Finder, and Weld Finder automate this process and improve efficiency.

- Joint Finder classifies joints by type — 1D, 2D, 3D, Plate (2D, 3D, Undefined), and Beam-Plate — ensuring that beam-to-plate connections are correctly recognized. For other beam connections, classification depends on element orientation, constraints, and defined recognition settings. Recognized joints can then serve as logical breakpoints for other tools.

- Beam Member Finder uses these joints to identify and segment beam members across Y, Z, and torsional directions. This tool automatically breaks members into submembers where necessary, accommodating structural details and orientation factors (e.g., strong/weak axis). Additional customizations like length factor and Cm Type can be applied to individual members to fine-tune calculations based on standards like AISC ASD 1989 Members (9th, 1989), AISC 360-10 Members (14th, 2010), API RP 2A-LRFD (1st, 1993), API RP 2A-WSD (21st, 2007), Eurocode 3 Members (EN1993-1-1, 2005), ISO 19902 (1st, 2007), ISO 19902 (2nd, 2020), and Norsok N004 (rev.3, 2013).

- Weld Finder locates welds and weld parts. It assigns crucial properties such as weld length, type, and throat thickness, which are essential for strength and fatigue analyses. For strength calculations, weld dimensions are defined, ensuring that weld strength can be properly considered in all directions (along the weld, perpendicular, and shear). For fatigue calculations, elemental stresses are automatically adjusted along the weld direction, minimizing setup time. Weld Finder enables you to set welded and nonwelded conditions across parts, filter welds by tensile or yield properties, and verify recognition settings.

Why It’s Beneficial: These tools streamline setup, enabling model components to be defined and adjusted quickly and accurately. This structured preparation enables precise alignment with simulation requirements and significantly improves the speed and accuracy of the overall workflow.

How To Implement: After initializing Joint Finder in Ansys Mechanical structural finite element analysis software, run Beam Member Finder in SDC Verifier to segment beams by direction and Weld Finder to identify welds across the model. Each tool offers customizable settings for geometry, load, constraints, and selection of the finite element analysis (FEA) model, enabling you to adjust selections to reduce recognition time and ensure the model is prepared accurately and efficiently for analysis.

For example, during a plate buckling verification, the panel recognition tool in SDC Verifier was used to automatically segment and classify panels, plates, and stiffeners within a structural model. As demonstrated in the video, the tool identified these elements with a single click while the filtering feature enabled clear visualization and verification. This streamlined approach ensures all components are accurately defined and ready for analysis.

We can recognize our panels, plates, and stiffeners in one click using the panel recognition tool. Filters help visualize these elements in different colors, confirming everything is properly segmented and ready for verification.

Tip 2: Simplify Load Cases With Integrated Load Tools

SDC Verifier offers a suite of load management tools to efficiently handle the complexity of load cases in your Ansys workflow. Whether dealing with a range of environmental, structural, or operational loads, these tools reduce the effort and potential for errors in defining and managing load scenarios.

FEM Loads

Using the FEM Loads tool in SDC Verifier, users can assign various forces, pressures, and complex loads such as Wind Load, Buoyancy Load, and Wave Load directly to their model components. However, accelerations and moments must be applied in Ansys Mechanical.

SDC Verifier offers an intuitive interface for aligning each load precisely where needed, and preconfigured standard settings help ensure alignment with industry codes.

Practical Tip: Setting up FEM loads this way accelerates the process and helps prevent overlooking critical areas that might otherwise be missed with manual load applications.

Predefined Load Cases

For more advanced load management, SDC Verifier’s Predefined Load Cases tool lets you automatically generate complex load combinations in compliance with standards like EN 13001, Eurocode, and ASCE 7-10. This tool enables you to assign individual loads by category, apply correction factors, and even set up additional load sets with reverse logic where needed.

- Load case standardization: Choose a predefined load standard to automate load case creation.

- Load categories: Assign loads (e.g., wind, snow, gravity) by standard category for quick grouping and organization.

- Load factors and positions: Customize load factors for each load set and control simultaneous/non-simultaneous application through positional grouping.

Example: A wind load (factor 1.5) and a gravity load (factor 1.35) can be grouped in the same position, while a snow load (factor 1.5) can be grouped in a different position. This enables a flexible, standards-compliant load scenario.

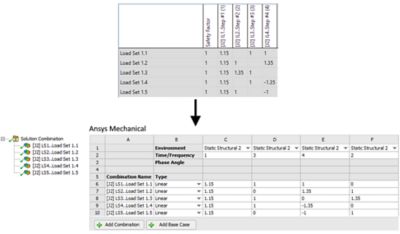

Load Sets

The Load Sets feature in SDC Verifier provides an efficient way to combine individual loads acting on a structure simultaneously. The software offers two primary load set types:

- Standard load sets: These allow for linear combinations of loads with specified factors for straightforward summation.

- Spectral load sets: Used primarily for dynamic analyses, spectral load sets calculate the result based on the square root of summed squares, making them ideal for categories affected by stress.

Once configured, you can export load sets directly to Mechanical software. Each load set becomes an individual solution step, maintaining the original load values and factors for accurate simulations. Alternatively, the Solution Combination export option generates cumulative combinations for more extensive assessments.

Tip 3: Accelerate Standards Compliance Checks With Preset Verifications

Compliance with recognized standards is essential in engineering workflows, particularly when ensuring safety, functionality, and regulatory adherence across diverse industries. With SDC Verifier integrated into your Ansys workflow, you can access comprehensive preset verifications aligned with a wide range of global standards, including Eurocode, ASME, DNV, ABS, AISC, etc. SDC Verifier’s standards verification tools provide an automated approach to structural checks, covering everything from buckling to fatigue and weld strength while remaining customizable for additional or proprietary standards.

For instance, standards checks in SDC Verifier include the following:

- Plate buckling checks for ABS and DNV standards, addressing varying loads on plates within structural assemblies.

- Member and weld strength verifications under ASME and Eurocode criteria ensure material resilience under expected stressors.

- Fatigue standards per EN 13001 and Eurocode 3 are ideal for cyclic loading environments.

The software supports extensive parameterization, enabling users to quickly configure the verification process for specific project requirements. Additionally, automated workflows streamline the compliance verification process, ensuring speed and reliability. Rather than manually defining parameters for each check, engineers can run a sequence of predefined standards to produce consistent, report-ready results, which is ideal for efficiently meeting project deadlines and regulatory expectations.

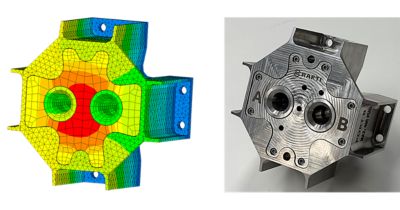

In the video demonstration, Eurocode 3 standards were seamlessly added and configured in SDC Verifier. Key parameters, including element positions, end conditions (rigid or nonrigid), and stress characteristics were predefined with just a few clicks. The plate buckling results, calculated using load group envelopes, clearly highlighted overstressed areas in the global X and Y directions. Legends were updated to improve visualization, enabling engineers to pinpoint compliance issues efficiently.

We used load group envelopes to calculate plate buckling. Overstressed areas for plates in the X and Y directions were highlighted, and legends were updated to ensure clarity.

Similarly, the DNV standards verification process demonstrated the same level of efficiency. Resistance factors, material properties, and buckling parameters were preloaded based on predefined templates, simplifying the setup. Results from plate buckling and stiffener checks were visualized in clear plots, with overstressed areas highlighted for quick adjustments to meet compliance.

Adding the DNV standard was seamless. Resistance factors and material properties were preloaded, and results for plate buckling and stiffeners were visualized clearly in plots.

With these tools integrated into Mechanical software, you can conduct rapid yet thorough compliance verifications with minimal effort, facilitating initial design approval and ongoing structural health checks.

Tip 4: Reduce Postprocessing With Automated Report Generation

Manual report generation can take up valuable engineering time, especially when projects require detailed, standards-compliant documentation. SDC Verifier’s Report Wizard and Report Designer tools streamline this process, providing automated, customizable report generation capabilities that help engineers create well-structured, project-specific reports directly within the platform.

Automated Report Creation With Customization Options

The Report Wizard enables engineers to quickly generate complete, standards-compliant reports by following a guided workflow. The wizard uses preset templates to automate data compilation, plots, and tables for essential items like model properties, load case results, and compliance checks. With this, engineers can produce a thorough report covering all necessary compliance checks in just a few steps.

For teams needing even more control, the Report Designer extends these capabilities, offering detailed customization options that allow for adjustments to fit specific project and stakeholder requirements. Engineers can create single report items, customize report layouts, and add specific chapters, comments, images, and data from external documents, providing the flexibility to create reports that are as detailed or concise as needed.

Key Features of the Report Designer

- Flexible layout control: Engineers can design custom report layouts, modifying headers, footers, margins, and fonts to match project standards. The Report Designer offers a table-based layout where rows, columns, and spans can be adjusted to organize content visually and functionally.

- Inclusion of essential project data: Engineers can integrate model descriptions, recognized elements, load summaries, and criteria plots tailored to meet regulatory or client-specific documentation requirements. For multiload cases, results are automatically organized by job, load, or selection, enabling structured data presentation.

- Enhanced result organization: Results can be sorted based on loads or selections, enabling engineers to present findings in the most relevant order. Furthermore, tables and plots for peak zones, load summaries, and component extremes are automatically grouped under designated sections, providing clear, logical data flows within the report.

- Direct export options: SDC Verifier allows reports to be exported in Word or PDF format with a single click, saving time on formatting adjustments and ensuring all details are preserved accurately.

Tip 5: Harness Batch Processing for Multiple Scenarios

Efficient post-processing is essential for interpreting results and identifying critical areas in structural analyses. SDC Verifier offers a suite of tools to streamline this process, allowing engineers to extract actionable insights and make data-driven decisions quickly.

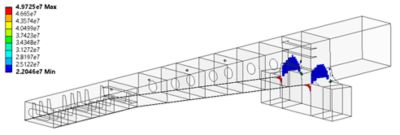

Peak Finder

The Peak Finder tool is a powerful feature for identifying peak stress zones across load cases. By setting filter criteria (e.g., value ranges or element percentages), users can quickly pinpoint critical zones based on specific parameters like stress or element force. Results are presented visually as plots and in detailed summary tables, making it easy to understand and analyze peak behavior.

Key features:

- Identify peak zones based on load or check results.

- Filter peaks by custom ranges, absolute values, or a percentage of elements.

- Generate zone-specific plots with customizable visualization options, such as elemental values or average values across zones.

- Export peak zones to diagrams or tables to evaluate the contribution of individual loads.

Practical example: Use Peak Finder to highlight overstressed areas in a complex model, enabling immediate visualization of zones that require further attention or design adjustments.

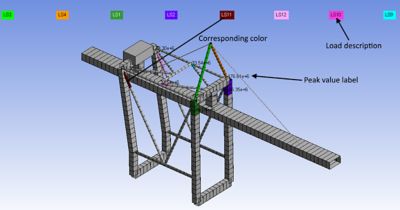

Governing Loads

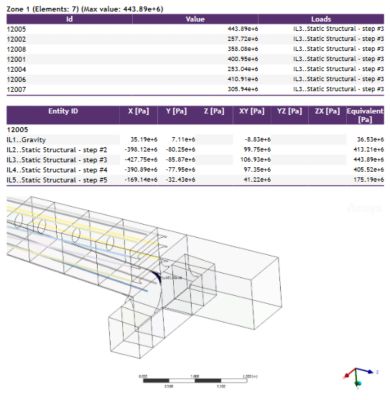

For models with large number of load combinations, the Governing Loads tool identifies critical loads that govern the behavior of the structure. This tool simplifies the analysis of load groups by narrowing down the results to the most impactful scenarios.

Key features:

- Define peak thresholds and select governing loads based on load groups

- Generate summary tables that list worst-case scenarios or detailed tables with all governing loads for each selection

- Plot governing loads visually and label critical zones for easy identification

- Export governing loads to a new load group for further analysis or comparisons

Use case: When analyzing a large structure with multiple load combinations, the Governing Loads tool helps you focus on the most significant results, saving time and effort.

Freebodies

The Freebodies tool calculates balanced forces and moments on specific parts of a model. It is ideal for substructure modeling or determining contact/connector forces.

Key features:

- Retrieve internal or external loads for any selection of nodes or elements

- Customize calculations by coordinate system, node selection method, and display mode (e.g., nodal sums, corner results, or overall summation)

- Visualize forces and moments with clear, organized tables and diagrams

Example: Use the Freebodies feature to analyze forces acting on a specific component of a ship structure, ensuring the integrity of critical connections under various loading conditions.

Why It Matters

SDC Verifier’s pre- and post-processing tools simplify working with large-scale models by handling both load application and result analysis. These tools help engineers:

- Efficiently manage and apply complex load cases

- Prioritize high-impact areas of a design

- Save time by automating load processing and result interpretation

- Enhance accuracy with customizable filters and criteria

With these techniques, you can speed up your analysis, reduce errors, and keep your projects on track. Try SDC Verifier for yourself — get a free trial and test all the features inside Mechanical software.