-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Noise, vibration, and harshness (NVH) are critical factors in the design and performance of electric machines. Excessive NVH can lead to reduced product life, increased maintenance costs, and customer dissatisfaction. Addressing NVH challenges early in the design stage is crucial to avoid major NVH issues later in the design stage.

Motor NVH analysis is inherently a complex multiphysics problem, combining both electromagnetic and mechanical analyses. This is because motor NVH issues typically originate from the interaction between electromagnetic forces and structural components, such as the stator. Therefore, a comprehensive understanding of both the electromagnetic and mechanical properties of the motor is essential for accurately predicting its NVH performance.

The Ansys Motor-CAD electric motor design tool is a dedicated solution for multiphysics simulation of electric machines across the full torque-speed range. It enables users to evaluate electromagnetic, thermal, and mechanical performance in one user interface. The integration of electromagnetic and mechanical modules in Motor-CAD software enables fast NVH analysis, facilitating iterative optimization of motor designs. This approach empowers users to adjust key design parameters — such as winding configurations, rotor and stator geometry, and structural materials — and rapidly evaluate their impact on NVH performance. This flexibility helps achieve an optimal balance among performance, cost, and NVH characteristics.

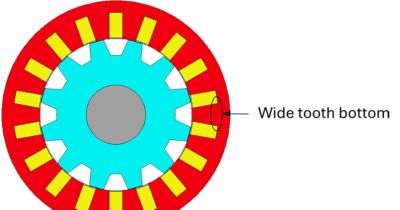

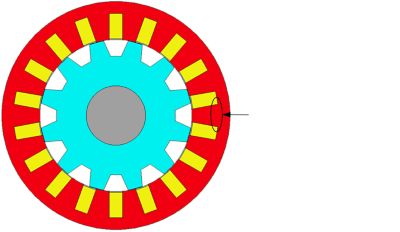

For rapid NVH analysis, Motor-CAD software uses an analytical mechanical model that simplifies the stator geometry into a simple ring structure. However, there is a limitation in stiffness calculation. For example, this can occur when the tooth bottom is wide, as shown in Figure 1, and the tooth geometry can affect the stator yoke stiffness.

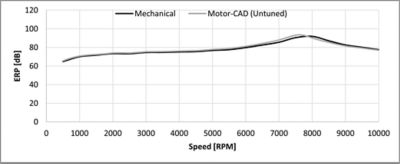

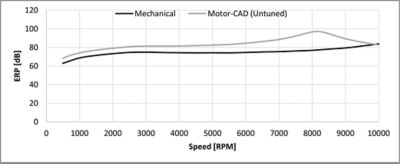

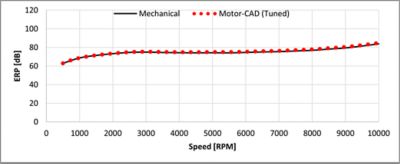

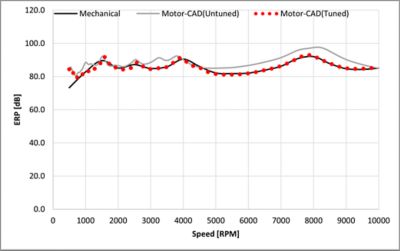

Figure 2 compares the untuned Motor-CAD equivalent radiated power (ERP) levels with the results from Ansys Mechanical structural finite element analysis (FEA) software for the motor in Figure 1. The Motor-CAD analytical model accurately predicts the 0th mode (breathing mode), excited by the third force harmonic. However, it does not effectively predict the sixth mode (hexagon mode), excited by the second force harmonic component, due to the influence of the wide tooth bottom on the stiffness of the stator yoke. The discrepancy in the sixth mode impacts the overall accuracy of the NVH prediction.

Figure 1. Stator with wide tooth bottom

Figure 2. ERP comparison between Ansys Motor-CAD software and Ansys Mechanical software: (top) 0th mode excited by third force harmonic, (bottom) sixth mode excited by second force harmonic

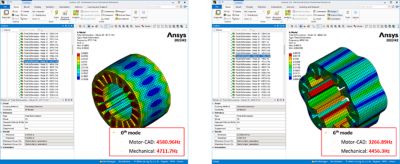

Figure 3 displays the modal analysis results from Mechanical software, showing that the 0th mode and the sixth mode occur at 4711.7 Hz and 4456.3 Hz, respectively. As shown in Figure 3b, there is a significant difference in the natural frequency value for the sixth mode, and the Motor-CAD NVH model can be tuned to align with the natural frequency value calculated from Mechanical software.

Figure 4 shows how to adjust the modal parameters to tune the Motor-CAD NVH model. To match the natural frequency of the sixth mode, the required stiffness value can be easily calculated using the equation shown in Figure 4b, which is derived from the definition of natural frequency.

Figure 3a (left) and 3b (right). Modal analysis results from Mechanical software: (left) 0th mode, (right) sixth mode

Figure 4a (left) and 4b (right). Modal parameter tuning

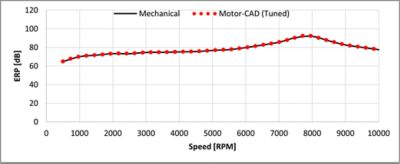

After inputting the new modal parameters, the Motor-CAD NVH model is automatically tuned, and the results of the NVH analysis are updated in a few seconds. The tuned model can predict more accurately the ERP level, as shown in Figure 5.

Figure 5a (top) and 5b (bottom). ERP comparison between tuned Motor-CAD software and Mechanical software: (top) 0th mode excited by third force harmonic, (bottom) sixth mode excited by second force harmonic

As shown in Figure 6, the tuned Motor-CAD NVH model correlates closely with the full finite element analysis results from Mechanical software.

Figure 6. Resultant ERP comparison between Motor-CAD software and Mechanical software

NVH tuning in Motor-CAD software is simple and straightforward to use, requiring only one modal analysis or test data to tune the modal parameters. Once the NVH model is properly tuned, we can run an NVH analysis in Motor-CAD software to better understand the noise characteristics across the full operating range. This will eventually help prevent redesigns and delays in product releases, saving both time and money in the long run.

Request a free trial of Motor-CAD software and watch a short video demo of Motor-CAD NVH model tuning below.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.