-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

November 24, 2023

All Charged Up and Somewhere to Go

Ample looks to the Ansys Startup Program to design its innovative modular EV battery swapping platform

Climate change is accelerating, and the imperative to swap our gas-guzzling rides for all-electric plug-ins is real. Yet, many are hesitant to make the change. Range anxiety, or the fear of running out of battery power, is one big factor fueling this hesitancy. Without the proper infrastructure in place, drivers may find themselves stranded on the way to their destination.

There’s also the issue of charging capacity. Plugging in and powering up can take anywhere from 4-10 hours using a 240V charger, making long distance travel a real chore. Ample is proposing a solution to charging challenges that is quickly gaining traction in the automotive community — modular battery swapping.

“Our mission is to bring electric cars to everyone,” says Steven Cho, director of computer-aided engineering (CAE) at Ample. “We believe that for the widespread adoption of electrification in personal and commercial mobility, facilitating the transition from gas to electric power has to be as fast, as cheap, and as convenient as gas.”

Simulation Inspires an Entirely New Way to Energize an EV

Someday, charging up your electric vehicle (EV) could be as simple as pulling up and swapping out your battery. Ample shortens the journey to fully charged to just under five minutes for any EV on its platform, regardless of battery density. Drivers can check into a swapping station, where their EV’s “empty” modular battery is quickly replaced with a “full” one before hitting the road again.

By breaking an EV battery pack into smaller modular components, Ample aims to create a modular battery system that can adapt to multiple vehicle sizes and shapes with varying battery capacities to accommodate everyone. To do this, the automotive startup is using simulation, accessed through the Ansys Startup Program. The program enables early to mid-stage startups with limited funding access to a full suite of multiphysics simulation software, plus high-performance computing (HPC), at an affordable price.

Typically, time and cost are the most common challenges in the automotive industry — challenges Ample faced and overcame with simulation. Simulation can significantly shorten design cycles and save money and time that Ample can spend elsewhere. Even when a physical test is required, simulation can efficiently narrow down the key variables involved to reduce the total number of physical prototypes.

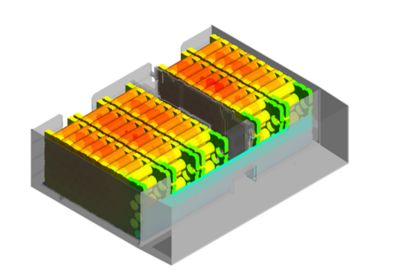

Ansys Fluent thermal simulations of Ample Battery modules using a multi scale multi domain (MSMD) - equivalent circuit model (ECM).

Ample also turned to simulation to address packaging and thermal management challenges, as well as other unexpected battery cell defects that could compromise vehicle safety. Various thermal and flow simulations in Ansys Fluent helped the team understand the basic physics and thermal flow behavior in the battery module structure, accelerating the time it took to achieve a final design.

“As a CAE engineer, I have been using Fluent from my college days and throughout my career in various applications such as automotive, solar, heat exchanger, and semiconductor,” says Cho. “At the beginning stages of our work, the Ansys Startup Program offering was perfectly satisfying our demands.”

Ansys solutions were also instrumental in developing swapping stations featuring simple, cost-effective robotics systems that are redundant, easy to deploy, and need minimal space to operate. Ultimately, simulation helped Ample arrive at a flexible design that can be deployed in days and support a wide range of vehicle applications — from small cars to large class three trucks in the same station, using the same modular batteries.

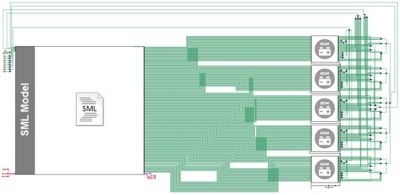

Ansys Twin Builder model (ROM) of Ample battery modules using ECM and LTI

Ample Democratizes Cleaner Travel for All

Perhaps the most interesting outcome of this effort may be in the modularity of the batteries themselves. The tech is great, yet the price of entry is still prohibitive for most consumers. Cho’s team, in working with original equipment manufacturers (OEMs), has another breakthrough solution in mind that will significantly reduce barriers to ownership.

“Instead of selling battery packs inside the car, we are trying to sell the vehicle without it,” says Cho, “Your new vehicle would come equipped with a swappable battery module. The battery module is not yours. You’re just paying for the electricity needed to fully charge it. This will be a real game-changer in terms of price.”

As you might expect, OEMs are lining up to hear about Ample’s solutions.

“Our modular battery swapping has the unique advantage of making it possible to make almost any electric vehicle swappable without requiring any modification to the vehicle,” says Cho. “We are engaged with a few of the largest automakers in the world to prepare their EVs to be sold with Ample’s technology. This enables them to solve a significant barrier to EV adoption, which is the availability of electric infrastructure and speed of energy delivery, especially to fleet partners for whom cost, and speed make a significant difference.”

There’s a lot of concern for the future of our planet. Behind the scenes, startups like Ample are running with some big ideas (and help from Ansys) that could change it. If you need simulation to help bring your dreams to life, the Ansys Startup Program can help.