-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

June 13, 2023

Drying Dynamics of an Agitated Filter Dryer Using Ansys Rocky

Downstream processing of active pharmaceutical ingredients (APIs) involves crystallization, filtration, drying, and milling unit operations. Drying is one of the most energy-intensive unit operations and is often the rate-limiting step in the overall API manufacturing cycle. Optimizing operating conditions such as pressure, temperature, and mixing is crucial to avoid API degradation during the drying process.

An agitated filter dryer (AFD) is widely used for its ability to conduct both filtration and drying unit operations in a single piece of equipment, thus minimizing product handling and operator exposure. To gain insight and ultimately improve the drying process, the impacts of impeller speed and two impeller types on solvent drying behavior were studied for a lab-scale, flat-bottom agitated filter dryer.

For drying, heat is provided from both the jacketed vessel walls and the impeller. Agitation of the wet cake during the drying stage is performed to achieve uniform heat transfer and avoid hot spots across the particle bed. An unoptimized AFD design will lead to agglomeration and/or attrition, which can adversely impact the particle size distribution (PSD) achieved at the end of the drying stage.

Modeling Agitated Filter Dryer Operations in Ansys Rocky

Ansys Rocky is used to evaluate the impact of geometry and operating conditions such as angular velocity, impeller shape, and impeller position on the solvent drying behavior in three different scales of agitated filter dryers. A constant particle size of 4 mm is chosen based on the studies performed in the scientific literature. In this blog, we share the results showing the drying times for different impeller speeds and impeller geometry and position comparing a standard pitched blade turbine (PBT) with results from an S-shaped impeller. You can download additional details and an overview of the scale-up study.

Right after filtration and before the drying process, the granular material resembles a wet cake-type of material. Wet cake is modeled by a spherical granular material using liquid bridge modeling, which is a pure discrete element method (DEM) approach to represent a liquid film between particles. With this approach, the adhesive and viscous interactions between the particles due to the liquid film are calculated without the need for computational fluid dynamics (CFD) coupling.

Initially, the liquid mass rate for each particle is around 18%. This represents a very wet granular media, simulating the wet cake in the initial stage of the drying process.

Optimizing Equipment Operating Conditions and Design Based on Drying Curves

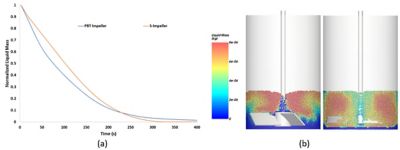

Liquid drying is simulated using the Liquid Drying by Heat Flux solver module in Rocky, which enables users to model liquid film evaporation due to the latent heat. Figure 1 shows the liquid drying curves at different agitation speeds and a snapshot of particles in the center plane colored by the liquid mass after 60 seconds.

Figure 1. a) Drying curve at different agitation speeds; b) Particles colored by liquid mass at a simulation time of 1 minute.

Figure 2 shows the impact of the impeller type on the drying curve. In this case, a two-blade, S-shaped impeller is compared with the PBT impeller. The simulation demonstrates that the S-shaped impeller results in a faster overall drying time.

Figure 2. a) Drying curve comparison; b) Particles colored by liquid mass at a simulation time of 1 minute between PBT and S-impeller.

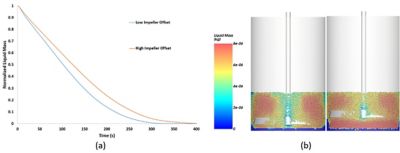

Figure 3 shows the drying curve at different impeller positions and the fine-tuning that can be done for geometry configurations to optimize drying time.

Figure 3. a) Drying curve comparison; b) Particles colored by liquid mass at a simulation time of 1 minute between two different positions of the S-impeller.

Such optimization studies can be easily performed by high-fidelity DEM simulations, providing valuable insights to improve the slowest and most energy-intensive step of the API manufacturing cycle. Although this study has considered upscaled particles for demonstrating filter dryer operations, Rocky can efficiently run high-performance, multi-graphics processing unit (GPU) processing, allowing fast simulations of either spherical or complex nonspherical particles and large particle count cases. This makes Rocky a practical and powerful tool for designing and optimizing filter dryers, as well as many other devices used in pharmaceutical, food, and other process industrial applications.

Learn how Ansys Rocky can help you.