-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

December 22, 2020

A Better Way to Generate and Deliver X-rays

Lumitron Technologies, Inc., a member of the Ansys Startup Program, is using Ansys HFSS and Ansys Fluent to design a new X-ray technology that combines accelerators with lasers to create higher energy, higher resolution X-ray beams that might be used simultaneously for imaging and treatment. The X-rays could be tuned to a narrow range of energies with small source size to provide greater contrast and resolution for imaging, while enabling novel treatment methods for radiosurgery.

When the company was founded by Chris Barty in 2018 in Irvine, California, they used Ansys HFSS because most of the initial employees were familiar with the product. “Then, when we learned about the deal that the Ansys Startup Program offered — combining thermal simulation and electromagnetic simulation in a single package at a low price — that's a deal we couldn't refuse,” says Yoonwoo Hwang, an accelerator physicist at Lumitron who started working on the new X-ray technology as part of his Ph.D. research project while at UC Irvine.

Visit the Ansys Startup Program

for more information

Ways to Make X-rays

The standard way that X-rays are created in a hospital is by aiming an electron beam at a metal target. The electrons slow down upon penetrating the metal and emit X-rays in the process. This produces a broadband radiation, most of which is filtered out. Some of the wavelengths that are not filtered out are absorbed by the tissues of your body without helping to make an image, so you might be getting more radiation than is necessary.

For scientific applications like crystallography, a synchrotron accelerates the electrons to high speeds to produce X-rays. If this radiation passes through a periodic magnetic field, the electron beam undulates or wiggles, creating higher energy X-rays. But a synchrotron can be a huge device consisting of a ring many kilometers long.

Just a small section of a building-sized synchrotron is shown here

To bring the system down to a more manageable size for clinical applications, in recent years researchers have been experimenting with lasers in place of the periodic magnetic field undulators. A laser beam is an oscillating electric field with a much shorter wavelength than the magnetic undulators at synchrotron facilities. If you collide a laser with an electron beam, the electrons wiggle. In doing so, they emit higher energy X-rays in a much more compact footprint, in the range of a few meters, suitable for hospitals.

Hwang explains the physics involved: To make electron beams for radiography, you need X-ray energies in the range of 10 kV and 100 kV. Using the synchrotron method, you would have to accelerate the electrons up to giga-electron-volt (GeV) levels, which would require an accelerator ring hundreds of meters long. “But in the laser collision method that we are developing, to make that same X-ray energy (10 kV-100 kV), you only need about 50 MeV (mega-electron volts), not GeV,” ” Hwang says. “And a 50 MeV electron accelerator is actually very small — just a few meters long.”

Why Simulation Is Needed for X-ray Design

Precise RF design and controlling temperature to maintain resonance in the accelerator is the key. Lumitron uses copper microwave cavities containing electromagnetic fields. “You can set up the field so that the electrons will ride only on the accelerating parts of the cavity,” Hwang says. But this requires very precise design to tune the cavities for optimal operation.

The cavities heat up due to the electromagnetic fields, which can distort the copper. Lumitron uses HFSS to simulate the RF structures and Fluent to simulate thermal deformations to be expected for various conditions. If the temperature of the cavities is slightly off, even by only 0.5 degrees, the RF source is not matched to the cavity. This will cause all the power to be reflected and damage the power source.

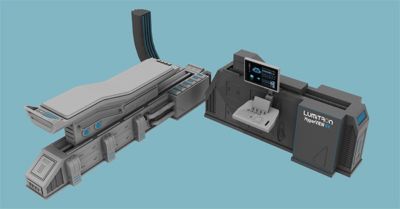

Lumitron Technology’s HyperVIEW X-ray system

It’s a careful balance between the heating caused by the electromagnetic field and any artificial cooling solution you apply. Excessive cooling can distort the cavities too. So, after they generate the proper electromagnetic fields from HFSS, Lumitron engineers then look at where and how much the structure deforms and use Fluent to stimulate what kind of cooling is necessary. Recent improvements in the accelerator design have pushed the operating parameters by a factor of 1,000. “We had to redesign the entire cooling structure and to do that, we have to carefully simulate the effects of the new cooling manifolds and other apparatus,” Hwang says.

Health Benefits of the Lumitron X-ray Design

The Lumitron design is an improvement over existing X-ray machines in several ways:

- A single energy beam. Unlike the broadband X-ray radiation that emanates from modern clinical machines, Lumitron’s design can finely tune the output to a single wavelength of X-rays. “If you want 50 kV X-rays, you will just have 50 kV X-rays,” Hwang says. “Your imaging system will be tuned to the most efficient energy. This will enable a lot of new imaging techniques.”

- A smaller spot size for higher resolution. Lumitron is able to focus the electron beam and the laser beam on to a very tiny spot, 10 microns or smaller. And that essentially becomes the source size of the X-rays, which determines how small a thing you can resolve in your image.

- Combined imaging and therapy. Tuning the accelerator to a higher energy can be done in a matter of minutes. So, you can use one instrument to image a tumor at low energy and then increase the X-ray energy to that spot to begin killing cells in the tumor immediately.

- A more targeted, effective therapy region. Using a metal-based contrast agent, like gadolinium, helps to locate a tumor more clearly. But there is another advantage of these metal particles. If you irradiate the region with X-rays having an energy just above the K-edge (sudden increase in X-ray absorption) for the metal, they release a lot of radiation locally. “This starts the cascade of thousands of electrons leaving the atom,” Hwang explains. “But these electrons are at a much lower energy, usually a kV or less, so they really can't travel very far — nanometers at most. So, if the metal particles are located in the center the cancer cells, this cascade will kill only the nearby cancer cells without damaging the rest of the healthy tissue.”

Improving Healthcare Through Simulation

The Lumitron X-ray design improvements could pave the way for combining medical diagnosis and therapy. The company’s technology has been called a new frontier for medicine.

“We are very devoted to imaging, diagnostics and therapy,” Hwang says. “The ability to do these things with one instrument while enhancing the contrast and delivering a lot lower X-ray dose to the patient — that is unique. And the Ansys Startup Program played a big role in making this research and development possible.”

For more information, visit the Ansys Startup Program.