-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

April 11, 2022

3D Printing Innovation Takes Off at NASA

When you hear the term 3D printing, you might think of a small product or a repair part easily produced on a tabletop machine. But if you work for NASA, you might instead imagine 3D printing a 7-foot-tall rocket nozzle capable of supporting long-duration space flight. Even more exciting, you might envision astronauts producing that rocket nozzle at a space station, or on a distant planet as they prepare for their trip back to Earth.

Fredrick Michael, a structural materials engineer at NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Alabama, is leading an effort to make these kinds of ambitious visions a reality with the Ansys Additive Manufacturing solution suite. Michael is an enthusiastic advocate of engineering simulation and other advanced tools that are turbo-charging NASA’s historic product development approaches — pushing the boundaries of both simulation and additive manufacturing.

“In 2015, NASA created a 25-year plan called Vision 2040, which emphasizes the importance of multiscale modeling and simulation-based design of materials and systems for aerospace applications,” says Michael. “Our partnership with Ansys and our focus on additive manufacturing, or 3D printing, are helping our team at MSFC honor that commitment to innovation. By leveraging new computational methods and advanced processes such as 3D printing, we’re doing our part to keep NASA at the forefront of global aerospace engineering.”

An Early Adopter of Additive Manufacturing

NASA has been a user and proponent of additive manufacturing since the earliest days of the technology’s commercialization. The space agency has combined its internal expertise with insights from industry and academia to pioneer new methods of printing rocket parts capable of powering journeys to the moon, Mars, and other destinations.

“NASA has invested in perfecting additive manufacturing techniques for a range of components, from smaller parts such as injectors to very large, single-piece rocket engines and their components either in single builds or multiple builds,” Michael says. “Additionally, we have begun to explore, via additive manufacturing and related computational modeling, large-scale tanks and structures. Last, but not least, our in-space manufacturing on Low Earth Orbit (LEO) and our Lunar Orbit and Lunar Habitats programs are rapidly developing and being paralleled by existing and needed computational modeling of the additive manufacturing and welding processes. Whatever the size of the finished part, there are a number of common engineering and production challenges that we use Ansys software to address.

“Primary among these challenges is ensuring that the printed parts will hold up well structurally over time when subjected to the extreme temperatures and physical forces associated with aerospace applications,” Michael continues. “Deformation and shrinkage are common, so we model the parts in Ansys, creating a sort of digital twin, and subject that virtual model to real-world conditions and harsh operating parameters such as high temperatures.”

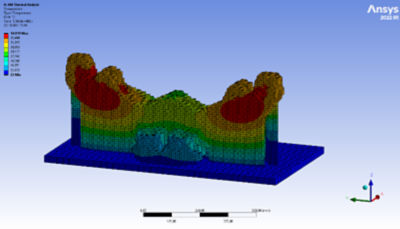

Ansys Additive 2022 R1 used for Thermal Analysis

The Additive Manufacturing suite also enables NASA to test different powders and alloys with varying grain structures and morphologies so engineers can minimize defects at the very smallest scale. “We can characterize the materials before the build and after the build,” Michael says. “We can look at their microstructure and their overall structural strength. We can quantify the effects of heat treatment. Ansys provides us with the advanced tool kit to assess these printed parts at every possible scale and under a wide range of possible conditions, which has really been invaluable.”

Optimizing Directed Energy Deposition Processes

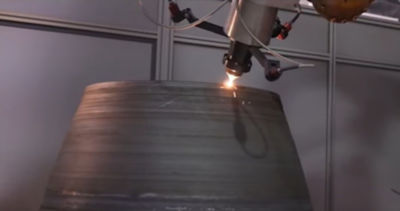

The Additive Manufacturing suite has proven critical to NASA’s success in using directed energy deposition (DED), a specialized production technique, to make very large components — including rocket nozzles measuring 7 feet tall and 5 feet in diameter.

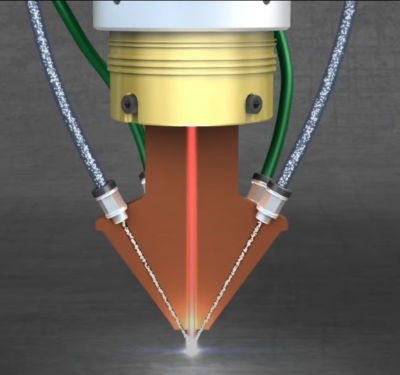

In the DED process, a robot moves a laser-powered 3D print head in a specific pattern as it deposits molten metal one layer at a time to create a predefined geometric shape. NASA uses DED to create large-scale rocket nozzles with complex shapes — and even internal cavities — more quickly and cost effectively than by relying on traditional forging methods. In fact, rocket nozzles can be produced via DED in just 30 days, compared to a year for more conventional manufacturing techniques.

In the DED process, a robot moves a laser-powered 3D print head in a specific pattern as it deposits molten metal one layer at a time to create a predefined geometric shape.

“Not only does Ansys software help us optimize the final product shape and its performance features, including materials properties, but it also has unique capabilities that enable us to optimize the DED process itself,” Michael says. We’ve been able to simulate the use of multiple laser heads, for example. We’ve been able to determine whether we should print the product right side up, or upside down. We also will be optimizing the laser’s path and the amount of material that it deposits. Ansys has collaborated with NASA to make the outcomes of this lesser-utilized additive manufacturing process easier to understand and control.”

3D Printing in Space: The Final Frontier

One of the more exciting developments at NASA is the possibility of using DED and other additive manufacturing techniques to produce repair parts or new equipment in space. As teams of astronauts explore other planets or live on space stations, they need to make products on demand instead of storing them. 3D printing would enable astronauts to easily and rapidly manufacture the exact parts, tools, and materials they need.

While the first 3D printer was launched into space by NASA in 2014, the technology is still not used on a widespread basis. According to Michael, simulation is proving essential in making additive manufacturing in space more feasible and widely adopted.

“Manufacturing parts in space brings a whole new range of temperatures and production parameters into play,” he says. “There’s no directionality, no gravitational pull, no buoyancy. Heating is accomplished by radiation and part-conduction, not convection if in vacuum. Traditional materials may not be available or feasible, as they are not adapted to the additive manufacturing process or the microgravity and vacuum conditions either partially or fully. It’s a completely different landscape. Ansys is critical in helping our team model that world and increase our understanding of it, reducing the need of resorting to process development and testing large matrices on somewhat limited resources in zero-gravity drop chambers or other physical testing elements, such as repeated microgravity parabolic flights or even the International Space Station (ISS).”

Complex internal coolant channels are easily manufacturable through additive technology.

Could Ansys itself be used in space to optimize 3D printing projects? “I think we’re just at the beginning of seeing what simulation and DED can accomplish,” says Michael, “and I applaud the efforts of Ansys to develop specialized capabilities for this emerging area.

“I can say with confidence that the software workflows created by Ansys have been very, very useful in getting NASA this far. Ansys software allows even our newest engineers to jump right in and start optimizing the additive manufacturing process. So, I’d say the full utilization of computational modeling of additive manufacturing and related manufacturing at every step of our terrestrial and in-space efforts as enabled by Ansys is what we envision the future of this collaboration to be,” Michael says.