ANSYS ADVANTAGE MAGAZINE

May 2021

Electrifying the Future of Air Racing with Simulation

By Ansys Advantage Staff

It’s arguably the most exciting motor sport in the world, it’s been going on for more than a century, and you probably have never heard of it.

Imagine eight compact, single-seat electric-powered propeller airplanes taking off at once, flying to a height of about 30 feet, and racing wingtip-to-wingtip around a 3-mile oval at speeds of up to 250 mph, and you will get a sense of the adrenaline-fueled excitement competitive air racing creates. Air racing has been championed globally since 2013 by Jeff Zaltman, CEO of Air Race Events, whose Air Race 1 has served as the world championship of air racing since 2015 and continues to go from strength to strength.

Like other elite motor sports such as automotive Formula 1, Air Racing provides a test bed for cutting-edge technology. With the growing importance of sustainability, just as Formula 1 created an electric equivalent with its Formula E series, Zaltman has launched Air Race E, where the planes are 100% electric, to help accelerate the aviation industry’s push to become even more sustainable. Ansys is the Official Simulation Software Partner of Air Race E, making simulation software, training and consultation available to the competing teams.

Ansys is helping to advance the state of the art of aircraft electrification by offering a comprehensive suite of multiphysics simulation tools to address some of the toughest engineering challenges the teams will face — including battery and battery management systems, power electronics, the electric motor, and the overall integration of the electrified powertrain system into the airframe. For some teams, this involves designing the entire aircraft from scratch; for others, it means integrating these electric systems into an existing airframe.

“These teams need to go from an idea to an airplane that is ready to race in an incredibly short time frame. Simulation is the only way to accelerate the design and development process such that their electric aircraft are certified to fly in time for the first qualifying events scheduled for the latter half of 2021,” says Roberto Bifulco, the Ansys technical account manager responsible for coordinating Ansys’ participation in the race. “Our software can help them achieve this goal, and we can also learn from the problems they need to solve, so it’s a win–win and one of the reasons Ansys decided to sponsor Air Race E.”

The Nordic Air Racing team poses with their Air Race E plane that is under construction. Image courtesy of Nordic Air Racing

Air Racing Builds an Electric Future

The first air race, the Prix de Lagatinerie, was held in France in 1909, just six years after the Wright brothers made the first controlled heavier-than-air flight at Kitty Hawk, North Carolina, in 1903. Air racing has continued in various forms ever since, often involving just one plane at a time racing against the clock.

Zaltman founded the Air Race 1 World Cup in 2013. He presided over the inaugural race in 2014 and the first World Cup of Air Racing in 2015. Teams race small, single-seat, propeller-driven Cassutt Special airplanes, which they modify within specific parameters to try to gain an advantage.

In Air Race E, the rules prescribe the platform each team must use. The requirements for the airframe, wings and weight of the aircraft are the same as for Air Race 1. With the substitution of electric power for an internal combustion engine, specifications for batteries include power not exceeding 150 kW (with an extra 25 kW boost capacity available over 30 seconds) and a maximum voltage of 800 V. In a 4-lap, 25 km (15.5 mile) race, the battery must be able to perform at full power for 5 minutes, with 10 minutes of reserve at minimum power. The goal is for total powertrain weight to not exceed 180 kg.

TeamNL 3D-printed this model on a 1:10 scale.

Two Approaches to Technological Challenges

“Designing a winning plane is not very straightforward,” says Dmitri Karelin, Technical Project Manager at Air Race E. “You can’t just go for the maximum power and say, oh, that should do it. The most powerful motor requires a bigger battery, which adds weight and may cause your plane to be slower than that of another team who uses a smaller motor and a smaller, lighter battery.”

Given these trade-offs, there is a lot of room for design variations within the rules, and each team will approach the challenges in a different way.

When Zaltman launched Air Race E in 2018, he attracted some of the teams already racing fossil-fuel–powered planes in Air Race 1 competitions, but he also stirred up interest among people who had never participated in air racing before. This has created two types of teams facing different challenges: the retrofitters and the build-it-from-scratchers.

Because simulation is new to many of the race participants, who are used to performing physical testing on new designs, Ansys held webinars in January 2021 to introduce all the teams to the simulation capabilities they can access and how to use them to overcome some of these challenges. We talked to two teams with different approaches to see how they are progressing.

Retrofitting

Nordic Air Racing of Norway brings together two organizations: Electric Aircraft Propulsion and Equator Aircraft. The team currently has 10 members, including volunteers. “We want to explore electric aviation at a higher level, and Air Race E gives us the opportunity to do that,” says Sathvik Rao, an engineer on the Nordic Air Racing team. “By entering an air race competition, you get to learn a lot and share your knowledge about the common problems that each team is facing and try to resolve them. That’s the mindset. Electrical aviation is in its infant stages, and it’s important to nurture it at the grassroots level right now.”

Left: Air distribution through the battery module. Right: Static temperature distribution in single battery module. Image courtesy of Nordic Air Racing

With no prior air racing experience, Nordic Air Racing bought a used Cassutt Special airplane to retrofit. Rao identifies five major challenges that they are facing:

- Changing the external geometry of the plane by giving the plane a longer, thinner nose

- Balancing the plane’s center of gravity because they are swapping out a heavy internal combustion engine for a much lighter electric motor

- Determining how best to cool the motor and batteries, both of which will be located in the engine compartment of the fuselage

- Developing a composite-based motor compartment to make the plane lighter

- Optimizing the battery design and performance

Nordic Air Racing is using Ansys Mechanical and Ansys Fluent to modify the nose of the plane to see how far they can maintain laminar flow over the fuselage and minimize the overall drag values. Mechanical is also being used to analyze the center of gravity problem. They have opted for air cooling through the whole thermal system, using a cowl, or air scoop, in the propeller hub that will let the air flow into and out of the system without producing too much cooling drag. Fluent is helping them to analyze the air flow in this region. Ansys Composite PrepPost will be used in developing the composite motor compartment.

That leaves the challenge of optimizing the battery performance. “You can speak to engineers in any industry based on electrification and ask about their main problem,” Karelin says. “The answer that everyone would give you? ‘It’s the battery.’ The battery is always the big challenge, the big danger and the big complexity in the system. That’s because the battery cannot be damaged and it cannot be overheated while you are flying. It’s a matter of safety. So the teams will rely on simulation.”

While Rao had used Ansys simulation solutions before in his aerodynamics engineering studies and thesis, which gave him some background for the Fluent thermal flow analyses, he was new to Ansys’ electronics and battery simulation solutions. It’s been an eye-opening experience for him. “I was quite surprised to see how Ansys software can integrate each and every parameter requirement for any sector, such as current, voltage, temp distribution and structural reliability of batteries,” Rao says. He is looking forward to taking advantage of these simulation capabilities in the near future as Nordic Air Racing tackles the battery challenge.

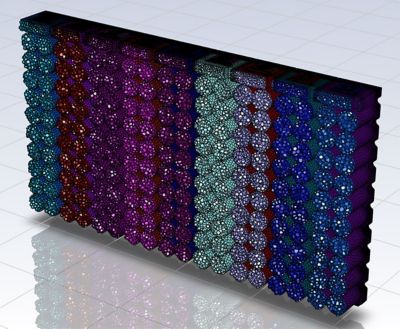

Volumetric meshing of battery pack to power electric airplane. Image courtesy of Nordic Air Racing

Building from Scratch

If you don’t have a plane to start with, obviously you have more work ahead of you. TeamNL in the Netherlands, with four members currently, didn’t let that stop them. “We just wanted to go for it all the way and design a plane so we can integrate it completely correctly,” says Rick Boerma, a lead engineer and longtime glider pilot on TeamNL. “We decided to integrate the batteries into the wings and then integrate the motors with the airframe to avoid having to modify an existing airframe, weight- and balance-wise. Starting from scratch can sometimes be an advantage.”

Boerma was familiar with Ansys software but had not used it before. “When Ansys decided to sponsor Air Race E, they said, ‘Hey, do you want to use this software?’” he says. “If you put that kind of a deal in front of us, who can say no?”

TeamNL sees the challenge as “one big packaging optimization task.” Because they have a small team (more volunteers are welcome!) and time and money are short, they have to choose the best components they can afford and put them together in the most efficient manner. Boerma says they want to keep the weight of the plane as low as possible, but to achieve the power to fly fast you need a big battery. If you use two small batteries, the current load is too high. So they are using relatively heavy batteries and trying to get the volume and the weight right.

They are using Ansys Discovery to develop the structure of the plane and achieve the right center of gravity with these weight loads. “It’s amazing what Discovery can do,” Boerma says. “I was really eager to get my hands on it. The speed of it and the ease of using it with the integrated Ansys SpaceClaim is really awesome. You can have a geometry and if you don’t like that hole there, you can just fill it in, and in five seconds you see the new stress distribution. I can even do topology optimization to get the shapes right.”

Exporting the geometry obtained in Discovery to Ansys Mechanical is just a few clicks away, so they will use Mechanical to give them the extra couple percent of accuracy to ensure they have a safe design. “Race pilots always want to push things further than they are allowed to,” Boerma says. “But safety is of course the number one priority in aviation. Of course, we want to go as fast as possible and try to win the race, but number one is getting the pilot back on the ground.”

The Near Future of Air Racing

Initial trial heats of Air Race E will be held in the last half of 2021 with the teams that have their electric-powered planes ready to go at that point. Sixteen teams have signed up for the competition, but there’s still time to get involved if you want to start your own team, because Air Race E will continue to evolve beyond its World Championship of Electric Air Racing planned for 2022. Ansys experts will be there to help all teams learn how to use simulation to solve their challenges throughout the process.

“Teams are in a race against time to get a plane ready for 2022, so being able to simulate plane and battery designs will prevent them from spending too much time going down a particular path and then having to backtrack,” Karelin says. “Being able to test a design change instantly is a big money saver, and these teams must certainly spend their money wisely.”

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.