-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS ADVANTAGE MAGAZINE

January 2021

Aim Higher with Optimization

By William Villers, CEO and Chief Engineer, Arsenal Advanced Methods, Nashua, U.S.A.

Here's a sales challenge for you: Try to offer a product to replace one that has been working well for decades in a conservative, risk-averse sector where the attitude is “If it’s not broken, don’t fix it.” Your new product is lighter and dissipates heat more efficiently, which is essential to its operation, and uses less material in its construction. Still, the industry wasn’t necessarily looking for a replacement. They are happy with the product they have now, and cost is not the main concern.

Arsenal Advanced Methods (Arsenal AM) is up against this challenge as they try to develop and market an innovative heat sink product to the DoD to keep electronic devices functioning optimally. These devices are responsible for radar image processing, radio communications, missile control, gun control and many other mission-critical operations. They have to be kept cool enough to function during military missions in harsh conditions where heat, vibration and shock can cause catastrophic failures.

Arsenal’s founders had many ideas for various products in mind for years, but using the engineering simulation tools they had available would take weeks to evaluate a single design, and they would have to explore hundreds of design variants to accomplish their goal. So, they kept putting off the launch of their startup, waiting for computers to get fast enough to work with the tools they had. When they heard about Ansys Discovery, they knew it was the tool they needed, so there were no more delays. In 2018, they became part of the Ansys Startup Program — designed to support early-stage startups, now with over 1,000 members — and officially went into business.

An Arsenal AM honeycomb handle for aircraft components

An Idea Born of Experience

After working in the aerospace and defense industry for 30 years, Arsenal’s founders knew every component of an aircraft inside and out. They couldn’t help but notice how certain parts could be made lighter by using less material. Like the numerous handles on electronic components that are just dead weight when the aircraft is operating — they only become useful when the plane is on the ground and a technician has to remove the component, then carry it to the maintenance station for inspection. Hauling this dead weight through the air costs fuel.

With their knowledge of topology optimization, Arsenal engineers realized they could design a lightweight version of these handles that would still do the job. They also knew that the components these handles are attached to are sometimes just machined aluminum plates, used as heat sinks to cool electronics onboard the plane, and switching to a 3D-printed honeycomb structure would save a great deal of weight, since there are up to 100 of these per airplane.

By saving a few pounds in each handle and heat sink, suddenly the payload is 100 pounds lighter. This translates into an extra 100 miles or 10 minutes of flight per mission, which could be the difference between success and failure. For space vehicles, the savings would be $10,000 per pound of payload. The return on investment is a great selling point.

Honeycomb Structures Are Key

The difficulty in getting new products approved by the U.S. military is showing that they perform better than the existing equivalent. It can be a challenge when the equivalent part has worked for 30 years without fail. But military aircraft engineers are familiar with honeycomb structures because large parts of an aircraft are now made of composite materials formed of honeycombs to give them strength and stiffness.

For the lightweight heat sinks, Arsenal engineers had to optimize the number, size, pitch and wall thickness of the aluminum honeycombs to achieve the necessary strength and stiffness required for duty in harsh environments involving shock and vibration. They used Discovery to quickly explore these variations in honeycomb geometry, with the help of Ansys SpaceClaim direct geometry manipulation of CAD surfaces, which allowed them to add smaller features to facilitate metal 3D printing. The optimal values determined by simulation for these honeycomb parameters varies by application, but in general they can reduce the mass by 40%.

While honeycombs reduce the amount of aluminum used compared to a solid block, their open spaces also reduce the thermal conductivity of the heat sink, which is detrimental to its operation. The air in the open spaces acts as an insulator rather than a conductor of heat. Experimental tests showed an unacceptable buildup of heat in certain regions of the honeycomb, so Arsenal engineers began looking for a solution. After exploring many materials for their thermal properties, they found that filling the honeycomb holes with graphite, an excellent heat conductor, made their heat sinks even better at removing heat than the solid-plate originals. The final design is a 3D-printed aluminum honeycomb filled with graphite, which still reduces the mass by 20% compared to the original solid aluminum plate structure.

Other flight applications have varying degrees of vibration during operations, so different honeycomb designs are needed to achieve the optimal stiffness. Unmanned aerial vehicles (UAVs) experience more vibration at different levels than a standard aircraft, for instance. A large gun onboard a military aircraft produces vibration and shock when it fires, and all electronic components onboard must be able to withstand these forces. So, each application needs a customized honeycomb design solution to meet operating requirements.

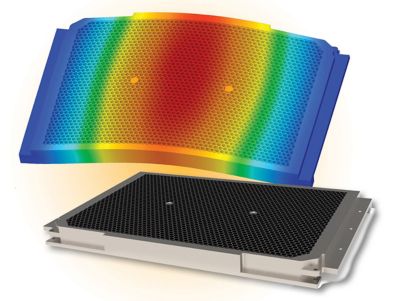

An exploded view of the Arsenal AM honeycomb heat sink with TPG core

Exploring Directional Loads

Another way of lightweighting a component is to use simulation to determine in which direction the load is being applied during an application. When you know how the load is being distributed, you can react to it, bend it and move it around the way you want. By reinforcing the component in that direction and removing material from other areas that bear no load, Arsenal engineers can reduce even more unnecessary payload weight.

Directional solutions can also be deployed to reduce vibrations. Using Discovery showed Arsenal engineers that they could build components that are rigid in one direction, yet flexible in another to damp out vibrations. Additive manufacturing made it possible to build these structures.

Arsenal’s prototype products have started to get some notice at conferences, so they are gradually overcoming the reticence to switch to a new solution that is built into the conservative military electronics sector. They plan to attend Air Force and Space Force pitching days where they can present their ideas to these governmental agencies to try to secure more funding for their startup. If successful, some of these funds will go into acquiring more Ansys simulation solutions so they can keep innovating quickly and inexpensively as new ideas arise.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.