-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS ADVANTAGE MAGAZINE

DATE: 2019

Structure a New Industry Standard

By Richard Mitchell, Principal Product Manager — Mechanical Ansys

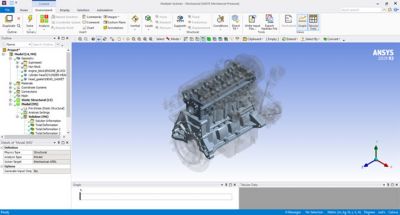

Growing concerns about energy efficiency — coupled with tightening regulatory standards — have forced structural engineers to explore advanced, lightweight materials and keep engineering margins as thin as possible. Companies are now evolving from highly trained structural engineers, often with doctorate degrees, to more diverse product development teams that include designers. Ansys Mechanical has accommodated this shift by embedding more complex capabilities in straightforward workflows.

When the technology behind Ansys Mechanical was introduced in 1969, it changed everything — streamlining and accelerating the complex analysis required to ensure the structural strength and stability of product designs. Since then, it has been leveraged by product development teams in every industry to cut time and costs, without compromising performance in mission-critical applications. Recent updates to Ansys Mechanical have made it even faster, more powerful and more capable of solving complex problems like fracture and acoustics. In addition, an enhanced user interface speeds adoption and simplifies common tasks — making the entire engineering team more productive.

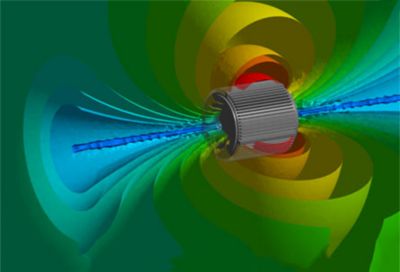

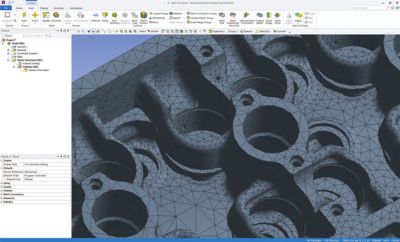

Nonlinear Adaptivity (NLAD) in Ansys Mechanical automatically remeshes models as the solution progresses.

"As engineering challenges and simulation needs continue to grow, Ansys Mechanical continues to expand its capabilities."

Ansys Mechanical is the Ansys flagship structural simulation solution used by thousands of product development teams around the world and in every industry. Ansys Mechanical was the first software to streamline, accelerate and automate the complex calculations involved in finite element analysis (FEA) and other structural studies. It has been used to develop hundreds of product designs that have, in turn, become industry standards.

The challenges faced by product development teams have changed significantly since the technology underlying Mechanical was developed in 1969 — and Mechanical has evolved to anticipate and answer these challenges. With thousands of users worldwide, Ansys collaborates with customers and listens to their needs to deliver practical, value-added software enhancements. With the increase in global competition in every industry, more frequent product launches and more innovative designs are required. Software developers at Ansys have responded with faster solvers and novel parallel processing schemes to drive enhanced speed and technical depth for structural analysis — capitalizing on improved hardware, cloud hosting and high-performance computing.

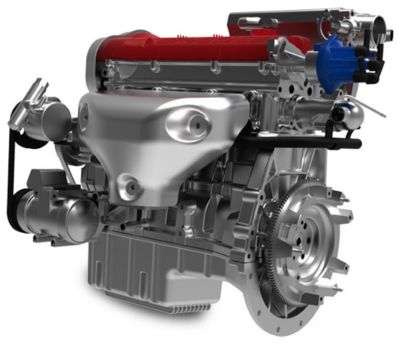

Growing concerns about energy efficiency — coupled with tightening regulatory standards — have forced structural engineers to explore advanced, lightweight materials and keep engineering margins as thin as possible. Ongoing enhancements to Ansys Mechanical equip product development teams to tackle these issues head on by modeling new materials and making intelligent trade-offs between material weight and structural strength.

Companies are now evolving from highly trained structural engineers, often with doctoral degrees, to more diverse product development teams that include designers. Ansys has accommodated this shift by embedding more complex capabilities in straightforward workflows — for example, fracture modeling or coupled field analysis — while making Ansys Mechanical easier to learn and use.

This issue of Ansys Advantage features many applications for Ansys Mechanical that would have been impossible to imagine even 10 years ago, simply because of their physical complexity, solver times and numerical solution size.

As engineering challenges and simulation needs continue to grow, Ansys Mechanical continues to expand its capabilities.

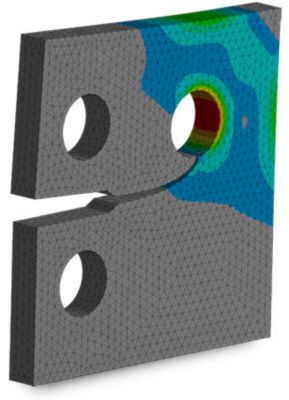

With SMART (separating morphing and adaptive remeshing technology) fracture modeling functionality in Ansys Mechanical, crack growth analysis is not dependent on the mesh.

FASTER, MORE INTUITIVE, EASIER TO USE

Ansys Mechanical contains a re-imagined user interface that is designed to help all users leverage its simulation capabilities while increasing speed and productivity for the entire product development team.

Based on customer feedback, the intuitive interface was designed with four tenets in mind:

- Ease of use. The software is designed to improve workflows, reduce mouse travel, easily identify key functions and provide access to shortcut keys that save time. A contextual ribbon groups similar commands, improving accessibility to the features needed to complete the current task.

- Discoverability. Relevant tools and data are at hand, with larger icons for common tasks and easy-to-use search engines. An expanded Tool Tips feature offers practical information and guidance with just a few mouse clicks, along with easier navigation. A Quick Launch option helps users easily search for a desired feature or interface, then automatically access it.

- Customization. Users can customize Ansys Mechanical through screen layouts, quick-access buttons and add-in user macros. A customizable graphics toolbar allows them to create new navigation systems that place their most used features within easy reach.

- Extensibility. Because Ansys Mechanical is employed by engineers to perform many tasks, it features an improved ability to add extra functionality through extensions via external software and custom code. This means Mechanical’s already expansive capabilities can be extended across many more engineering applications

MORE POWERFUL MODELING CAPABILITIES

Increasing consumer demands, harsher operating conditions, tightening regulations, the incorporation of smart functionality — all these factors contribute to more complex problems and numerically larger solution sizes. Ansys Mechanical features a range of functionality aimed at managing this complexity, while delivering a higher level of modeling and solving accuracy. A few of these new features include:

- Mixed-dimension analysis. Rendering and solving an entire, highly complex product design in 3D is time-consuming and expensive — and, often, it is simply not necessary to model the entire design in high detail. Ansys Mechanical supports mixeddimension analysis, in which structurally important parts of the design are modeled in 3D, while other aspects can be geometrically modeled in 2D, 2D-axisymmetry or even 1D. This balances the need for accuracy with greater speed and cost-effectiveness.

- Enhanced SMART fracture modeling. In the past, accurately predicting crack growth required expert analysis to construct the mesh correctly. Thanks to SMART (separating morphing and adaptive remeshing technology) fracture modeling functionality in Ansys Mechanical, crack growth analysis is not dependent on the mesh — and will not be influenced by model setup. Fracture modeling is faster and more accurate, and requires much less special expertise.

- An automatic mesh-based connection for shell and beam models. Patent-pending batch connection technology in Ansys Mechanical provides a fast, fully automated, high-fidelity way to connect large beams and shell structures. No shared topology is required, and intersections among parts are resolved at the mesh level. Backed by a high-speed quad mesher, this functionality supports a meshing and connection time of just a few minutes, even when more than 15,000 beams and sheets are involved.

- Improved acoustic analysis. Advanced nonlinear capabilities in Ansys Mechanical make it capable of assessing the complex problem of acoustic noise — which is becoming more critical because of stricter noise regulations. Features include waterfall diagrams and plotting of noise levels at various motor speeds in a single graphic. A sound file creation feature means engineers can hear what they are working on, well before it is built.

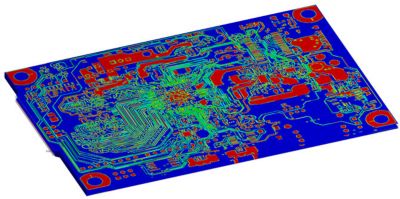

Accurate printed circuit board modeling is critical for electronics reliability.

SUPPORT FOR NEW MATERIALS AND PROCESSES

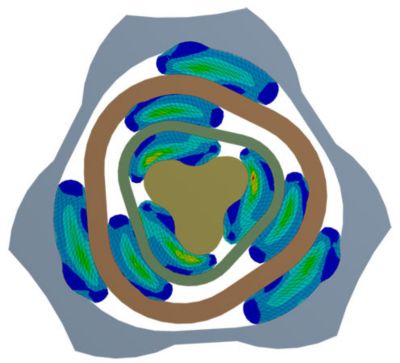

Ansys Mechanical includes expanded capabilities for capitalizing on two of the most important trends in product development today: the ever-increasing use of composite materials and the growing adoption of additive manufacturing (AM) production methods.

A specialized capability in Mechanical, Ansys Composite PrepPost, features upgraded modeling capabilities so engineers can build models layer by layer — reflecting the way composite materials are actually structured. Product development teams can more accurately predict delamination and other sources of structural failure. In addition, improved algorithms more precisely capture failure modes and materials performance.

Ansys Mechanical users can also simulate additive manufacturing workflows to optimize designs for a range of printer and material configurations. They can understand and predict the stresses and deformations that may occur as a result of thermal and structural stresses during the manufacturing process. Based on these insights, engineers can optimize the AM part build strategy and support structures upfront — minimizing the costs associated with materials waste and unnecessary test runs.

Ansys Mechanical has a new user interface designed to help different types of users leverage its simulation capabilities, allowing the entire product development team to be more efficient.

A Quick Launch option helps users easily search for a desired feature or interface, then automatically access it.

IMPROVED DATA ACCESS AND MANAGEMENT

Following the Ansys acquisition of Granta Design, Mechanical now offers new capabilities that reflect Granta’s expertise in materials data management, curation and selection. As development teams take advantage of next-generation materials and manufacturing methods like AM, Granta’s data can help them make smart decisions, ensure simulation accuracy and more effectively predict how products will perform.

With more than 600 materials — including metals, plastics, composites and AM powders — now embedded within Ansys Mechanical, product development teams can significantly reduce the time spent looking for material properties as they set up their models.

Simulating large assemblies requires efficient workflows and, often, many materials.

The Ansys GRANTA Materials Data for Simulation data package, which is part of Ansys Mechanical, covers virtually every material type and provides fast, easy access to the key data needed to perform structural analysis.

BUILDING FOR THE FUTURE

The recent enhancements to Ansys Mechanical are diverse, ranging from universal improvements in the interface to changes in the way very specific problems, like fracture, are solved. All these updates have one thing in common: They are based on real-world feedback from the customers who use Mechanical every day.

ANSYS SHERLOCK: NEW CAPABILITIES FOR ELECTRONICS DESIGN

With the acquisition of DfR Solutions, Ansys now offers a turnkey technology for analyzing the physics of failure for electronics systems and their components. Part of Ansys Mechanical, Sherlock Automated Design Analysis helps electronics manufacturers meet the need for smaller, denser package sizes — while ensuring that products can withstand drops, heat, cold and moisture.

Engineers can use Ansys Sherlock’s validated algorithms to subject their product designs to temperature fluctuations, thermal cycling, power– temperature cycling, thermal shock, random vibration, harmonic vibration, mechanical shock and flexure. By identifying and addressing any potential performance or manufacturing issues early in the design cycle, engineering teams can launch innovative products much faster, and at a lower cost.

In building a virtual product model, development teams can choose from Sherlock’s library of over 500,000 components — including a variety of parts, packages, materials, solders and laminates — as they quickly generate an FEA model. They can simulate a range of operating conditions on this model by capitalizing on Sherlock’s close integration with other Ansys solutions, as well as third-party CAE tools.

A significant portion of product development costs for electronics are spent on the test–fail–fixrepeat cycle. By enabling electronics development teams to simulate the lifetime performance of their products at the component, board and system levels — in the earliest stages of design — Ansys Sherlock helps minimize that financial investment, while maximizing product integrity.

At Ansys, we are focused on understanding our customers’ challenges and responding with best-in-class simulation capabilities that are constantly evolving. These capabilities go beyond Ansys Mechanical to encompass our entire portfolio. Mechanical may be our flagship product, but it integrates with our newest products, like Ansys VRXPERIENCE, which can be used to generate audio files to better address complex problems like acoustics.

Tools that are relevant for the task users are working on help speed workflows inside Ansys Mechanical.

Fifty years after the Ansys FEA software technology revolutionized product design and development, Ansys remains committed to identifying the most innovative, advanced simulation capabilities and placing them into the hands of users — where they can have a dramatic impact on our customers’ success. No matter how the business world and technology continue to evolve, that will remain our customer promise.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.