Exploring Sustainability in Additive Manufacturing

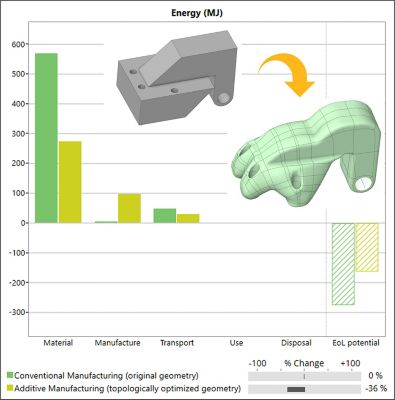

Discover how manufacturing impacts the environment, comparing conventional machining vs. Additive Manufacturing, amid the current climate crisis using Ansys Granta EduPack and Ansys Discovery. This case study compares these methods, emphasizing sustainability principles and design possibilities like topology optimization. Explore insights to integrate sustainability into engineering curricula, empowering students to tackle real-world challenges with eco-friendly practices. We highlight the potential of AM for lightweighting, offering significant energy savings and reduced CO2 emissions compared to conventional machining methods, while acknowledging its downsides from a sustainability standpoint, such as the energy-intensive nature of certain AM processes.

Learning Outcomes

- Understanding the current climate crisis and the mitigating sustainability principles

- Application of eco-friendly design principles

- Setting up and analyzing the life cycle audit of a product

- Critical thinking on the trade-offs of using additive manufacturing

- Learning the application of topology optimization: setup, results analysis and evaluation

Applicable Courses for Use

- Digital manufacturing technologies

- Sustainable development

- Intro to 3D printing processes & theory

- Near-Net-Shape Manufacturing

Downloadable Content

- Case Study PDF and Bracket Discovery file