Aeration is a key action in wastewater treatment. This step provides air to microorganisms that help breakdown organic matter, with H20 and C02 as the byproducts. However, aeration is also an extremely costly process that requires large amounts of power for compressors to effectively aerate massive pools of water. Even the slightest increase in compressor efficiency will lead to substantial savings.

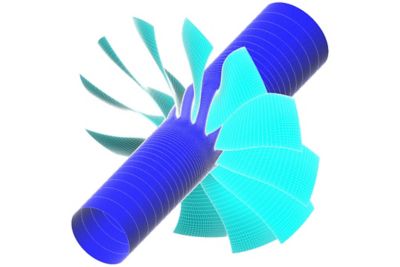

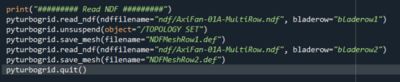

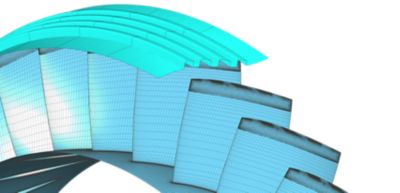

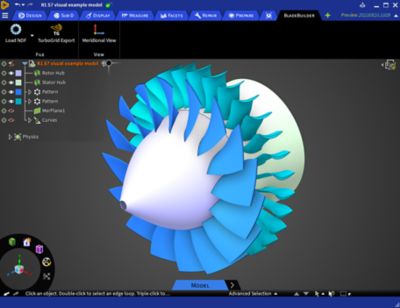

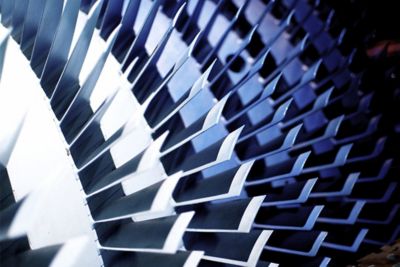

Turbomachinery engineers at Continental Industrie chose Ansys fluid tools to improve their existing compressor design. Before simulation, the engineers used Ansys TurboGrid to automatically produce hexahedral meshes for all their bladed components (inlet guide vanes, impeller and diffuser). The software produced tailored, high-quality results which allowed them to perform in-depth and accurate simulation. The mesh was just one step during the design process, but TurboGrid allowed them to start simulation faster, and spend more time on design optimization.