Product Specs

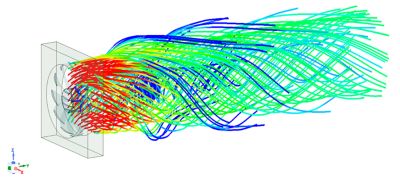

Perform conduction, convection and radiation conjugate heat transfer analyses, with many advanced capabilities to model laminar and turbulent flows, and species analysis including radiation and convection.

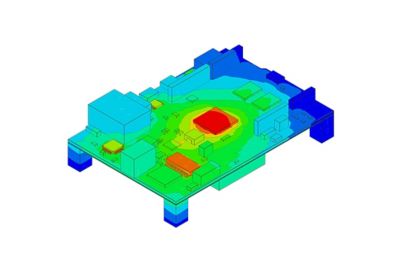

Ansys Icepak is a CFD solver for electronics thermal management. It predicts airflow, temperature and heat transfer in IC packages, PCBs, electronic assemblies/enclosures and power electronics.

Ansys Icepak provides powerful electronic cooling solutions that utilize the industry leading Ansys Fluent computational fluid dynamics (CFD) solver for thermal and fluid flow analyses of integrated circuits (ICs), packages, printed circuit boards (PCBs) and electronic assemblies. The Ansys Icepak CFD solver uses the Ansys Electronics Desktop (AEDT) graphical user interface (GUI).

Perform conduction, convection and radiation conjugate heat transfer analyses, with many advanced capabilities to model laminar and turbulent flows, and species analysis including radiation and convection.

Creotech implements leading-edge methodologies developed by the European Space Agency to design, assemble and integrate critical equipment that meets space standards.

Repairing orbiting microsatellites is impossible due to extreme logistical challenges. Satellite engineers must ensure that equipment is space-proven and extremely reliable before launch. Creating individual satellite components generates high costs, requiring satellite integrators to meet stringent design requirements and satisfy high production process standards. Creotech Instruments’ use of multiphysics simulation effectively addresses these complex challenges.

July 2024

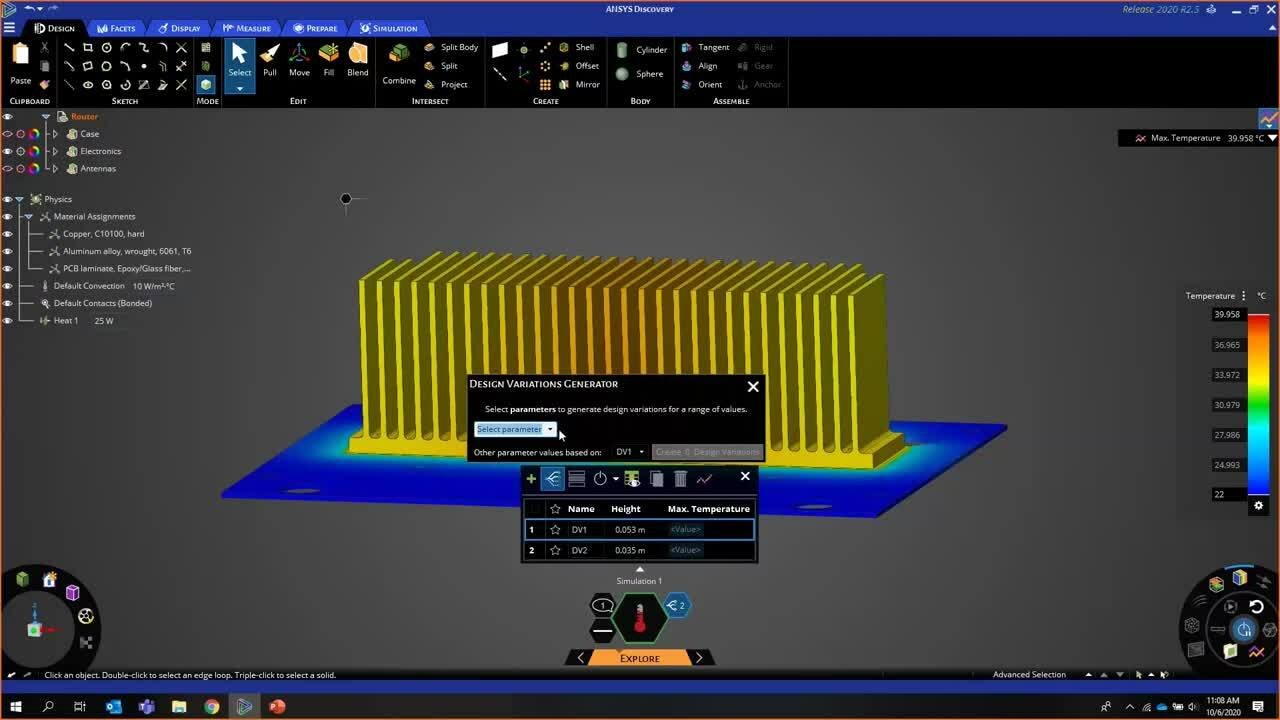

Ansys Icepak delivers new capabilities and improvements in performance, meshing, and modeling in 2024 R2.

Icepak can now automatically divide complex models into coupled subdomains and generate a mesh, which enables initial mesh generation and faster time to results.

With CAD-centric (mechanical and electrical CAD) and multiphysics user interfaces, Icepak facilitates the solving of today’s most challenging thermal management problems in electronics products and assemblies. Icepak uses sophisticated CAD healing, simplification and metal fraction algorithms that reduce simulation times, while providing highly accurate solutions that have been validated against real-world products. The solution’s high degree of accuracy results from the highly automated, advanced meshing and solver schemes, which ensure a true representation of the electronics application.

Icepak includes all modes of heat transfer — conduction, convection and radiation — for steadystate and transient electronics cooling applications.

Work Smarter with Product Bundles

Improve wireless communications, boost signal coverage and maintain connectivity for antenna systems, predict product performance and establish safe operating temperatures with these product pairings.

| Electromagnetic Losses with Thermal Coupling For Temperature-Dependent Antenna Performance Assessment (Icepak & HFSS) |

|---|

| Ensuring the thermal stability of antenna-enabled 5G infrastructure, automotive radar, IoT devices and mobile electronic devices is critical in producing expected behavior. Power hungry activity such as video calls, online-based games or varying environmental conditions causes significant swings in device temperatures. If a phone’s battery becomes too hot, it can lose charge or even create safety issues. Also, high temperatures can affect other electronic components within a phone and impact RF antenna performance. Breakdown of a phone’s connectivity with mobile carriers, Bluetooth or Wi-Fi is traceable to thermal problems. You can predict these issues before you build the hardware by simulating your design using Ansys tools. For example, electrical engineers can dynamically link Ansys HFSS and Ansys Icepak in the Electronics Desktop to simulate the temperature of the antenna. Based on the electromagnetic and thermal coupling solutions, they can modify antenna design and predict antenna efficiency and the overall thermal and EM performance of the product. These EM and thermal simulations help to improve wireless communications, boost signal coverage and maintain connectivity for antenna-enabled systems. |

| Board-Level Electrothermal Coupling (Icepak and SIwave) |

| Even a marginal rise in temperature can affect the performance and reliability of electronic components, leading to system-wide problems. Board-level power integrity simulations within SIwave can be combined with Icepak thermal simulations to get a complete picture of a PCB’s electrothermal performance. SIwave and Icepak automatically exchange DC power and temperature data to calculate Joule heating losses within PCBs and packages to obtain highly accurate temperature field and resistive loss distributions. These DC electrothermal solutions let you manage the heat produced by your designs and predict thermal performance and safe operating temperatures of chips, packages and boards. |

ICEPAK RESOURCES & EVENTS

Learn about the latest updates and newest functionality in Ansys Icepak and Mechanical in AEDT.

This webinar showcases Icepak’s solutions for power electronics.

This webinar will demonstrate an automated process of thermal modeling of printed circuit boards.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).