-

-

Software gratuito per studenti

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

-

Connettiti subito con Ansys!

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Paesi e regioni

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

Prodotti & Servizi

Scopri

Chi Siamo

Back

Prodotti & Servizi

Back

Scopri

Ansys potenzia la nuova generazione di ingegneri

Gli studenti hanno accesso gratuito a software di simulazione di livello mondiale.

Back

Chi Siamo

Progetta il tuo futuro

Connettiti a Ansys per scoprire come la simulazione può potenziare la tua prossima innovazione.

Customer Center

Supporto

Partner Community

Contatta l'ufficio vendite

Per Stati Uniti e Canada

Accedi

Prove Gratuite

ANSYS BLOG

February 16, 2024

Thermal Management in Wireless Charging: Challenges and Solutions

By enabling the transfer of electrical energy through electromagnetic induction without direct electrical contact, wireless chargers make it possible to power our phones, watches, tablets, earbuds, and more without the clutter of cables and cords. However, with an increasing demand to charge electronic devices faster, thermal management is important to prevent overheating problems, especially as the electronic devices become smaller and more portable.

What Causes Wireless Chargers to Overheat?

Wireless chargers use electromagnetic induction to transfer energy from the transmitter coils in the charger to the receiver coils in the device. During charging, you may notice that both the device and the charger become warm to the touch. This is due to power dissipation caused by electromagnetic losses in the charger components, which produces heat.

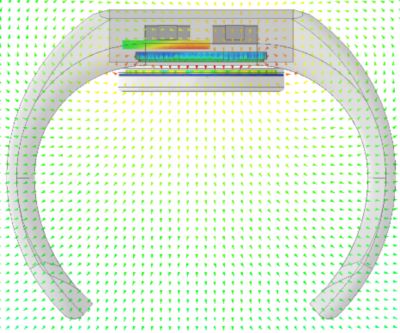

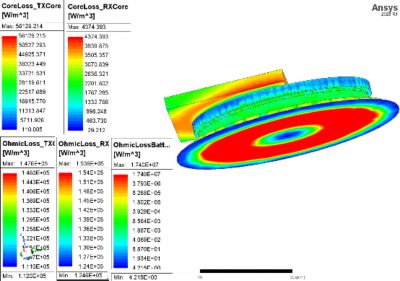

Simulated magnetic flux intensity vector and overall loss distribution of a wireless charging smart watch in Ansys Maxwell

Energy Transfer in Wireless Charging

Electrical energy is converted into a magnetic field by a device’s transmitting coil, then back to electrical energy by the receiving coil.

To limit energy loss and maximize charging efficiency, proper alignment between the transmitter coils and the receiver coils is necessary. Magnets in both the charger and receiver give users that “locking” sensation when the correct charging position is achieved.

Thermal Challenges in Wireless Chargers

In addition to coil alignment, wireless chargers have unique thermal challenges that must be addressed to ensure user safety and device performance.

Compact design: Small enclosures limit the options for integrating thermal cooling systems into chargers.

Standards compliance: Regulatory requirements must be met to ensure the charger functions within safe operating limit (under 44° C for skin pain threshold).

Variable conditions: Real-time changes such as load and ambient temperature require wireless chargers to be able to adapt.

Finding Strategies for Effective Thermal Management

The main challenges in thermal management of wireless chargers are similar to those seen across other electronics — the demand for faster charging and smaller devices. Consumers want a quick, convenient charging solution that also fits in their pocket. But to keep the overall footprint small for smartwatches or other small-size consumer electronic devices, adding bulky cooling solutions like fans may not always be possible. Engineers adhere to safe thermal thresholds when designing solutions for small spaces by looking to alternate cooling methods, such as those listed below.

Material selection: Choose materials like silicon-based materials that have higher thermal conductivity compared to resin materials to help improve heat dissipation, like in smartwatch cases.

Component placement: Optimize component locations and dimensions through a parametric sweep study to prevent the concentration of heat-generating components.

Ventilation: Incorporate natural or forced airflow around components to dissipate heat and promote thermal cooling.

Thermal insulation: Surround heat-generating components with materials that minimize heat transfer to adjacent areas.

Heat sinks: Provide pathways and surface area can help draw heat away from the heat source through thermal fins.

System efficiency analysis: System performance can be evaluated by considering the magnetic, thermal, and power electronics aspects of wireless chargers to obtain a faster charging experience for the consumer.

When considering different thermal management options such as material selection, component placement, and enclosure types, designers have a lot of choices. Using simulation for wireless charger design can help the electronic designers validate their thermal management strategies and optimize their designs before prototyping. Simulation software such as Ansys Maxwell, Ansys Icepak, and Ansys Granta can help designers see how each choice will affect their goals across a variety of performance scenarios.

What is the Future of Wireless Charger Thermal Management?

By keeping our devices cool while they charge, thermal management ensures fast, efficient energy transfer while maintaining the safety and longevity of our electronics. New thermal cooling innovations like the ones below will fuel our always-on lifestyles, making wireless charging even faster and more convenient.

Continuous charging: Uses radio waves to charge devices any time they are within range of an over-the-wire charger.

Embedded chargers: Integrate wireless charging into every element of our daily lives, including public transportation and furniture.

Universal standards: Create worldwide compatibility by making charging across device type and manufacturers seamless for users.

Learn more by viewing our on-demand webinar, “The Art of Optimizing Efficiency and Thermal Performance in Wireless Chargers.”