Discover More

By accelerating simulation with artificial intelligence, machine learning and deep learning, engineers are empowered to work with large, complex design more quickly – without sacrificing accuracy for speed.

Discover how visionary companies are leveraging the power of artificial intelligence (AI), machine learning (ML), deep learning (DL), and simulation to take a leap of certainty when solving complex engineering problems.

Engineers use simulation to ask the "what if questions" and predict how complex systems behave in the real world, from tiny microchips to commercial airliners. Ansys AI pushes the boundaries of what's possible even further. With our AI-augmented solutions, engineers can go beyond what they thought was possible, such as

Simulation at the Speed of AI:

Using a cloud-enabled machine learning platform developed for simulation, engineers can reliably predict performance with lightning speed.

Transforming the User Experience:

With Ansys AI-based virtual assistant, users can perform simulation tasks, ask support questions, or even create custom learning courses, all using natural language queries.

Solving the Insolvable with AI Add-ons:

Ansys AI enhances the simulation capability for complex use cases across the product portfolio. Users can deliver more accurate results and capture more details.

From the earliest stages of design and analysis, simulation improves workflows and increases quality and accuracy. Read how, through the application of artificial intelligence and machine learning, Ansys customers are pushing those boundaries even further.

Using Ansys technology, Bosch is creating digital models that take advantage of the capabilities of artificial intelligence (AI) and machine learning, and redefine electric vehicle design.

Discover how AI/ML-powered simulation is empowering Seagate Technology engineers to achieve the highest possible accuracy in streamlined development workflows.

Ansys’ best-in-class simulation solutions will help LG to develop their next-generation technologies with a focus on sustainability and digital transformation.

Ansys helps Juniper achieve highly predictively accurate power integrity signoff in significantly less time with a massively parallelizable design methodology that achieves greater switching coverage and improved reliability.

Achronix leveraged Ansys’ semiconductor simulation software to safeguard its latest chip design with thermal reliability and power integrity of intellectual property (IP) blocks and more.

A leader in systems engineering, SPEC Innovations is applying Ansys simulation solutions to develop a digital twin of a lunar rover to better enable Moon excavation in response to NASA’s Break the Ice Lunar Challenge.

Learn how Ansys Fluent can make effective use artificial intelligence (AI) to improve performance without compromising accuracy. Initial results show an 86X speedup.

Michael P. Brenner is the Michael F. Cronin Professor of Applied Mathematics & Applied Physics and a Professor of Physics at Harvard University. Brenner is also a Research Scientist at Google Research. He presents an overview of his work with Ansys and Google Research in “Machine Learning Convective Discretizations through User-Defined Functions in Fluent.”

Watch this webinar to discover how AI/ML can give your business the competitive edge and shorten the time to market.

AI/ML-based methods bring the ability to make use of historical data. Typically, when a volume of data is collected, there is a responsibility to sort through that information to pull out what is most needed, what is less valuable, and what should be discarded. The less useful or discarded data often gets stored away in old formats on computer hard drives, becoming mainly inaccessible and seemingly worthless. However, AI/ML thrives off a backlog of data and makes excellent use of them, turning obsolete legacy data into high-value assets.

Join this webinar to learn how AI/ML can benefit from unused or old data by recycling them to use as training material. Using past simulation results and data to learn and approach new design challenges is similar to leveraging the expertise of a team of senior designers but with a more significant advantage.

By accelerating simulation with artificial intelligence, machine learning and deep learning, engineers are empowered to work with large, complex design more quickly – without sacrificing accuracy for speed.

2023 R1 brings new features to Ansys Mechanical that enable users to perform more accurate and efficient structural simulations. This webinar will cover the top highlights in Mechanical for this release. Gain insight into the computational resources required to solve a simulation, including expected solve time and memory usage, by using the AI/ML-powered Resource Prediction feature.

How can autonomous development teams working on L3+ systems ensure that they are safer than a human driver while affordable for the business model? For a sustainable business model solution, an intensive trade-off between performance and safety is required in AD system development. Learn how Ansys solutions address critical technical challenges in safe system design and AV Software development.

In this webinar, our panel of experts will discuss how to bring together the best of AI and physics to create hybrid digital twins. Hybrid digital twins implement advanced techniques including physics simulations and virtual sensors. The panelists will also look inside the AI/physics work already underway thanks to the liaison between the AIoT User Group and the Digital Twin Consortium.

As the world draws near to the reality of fully autonomous automobiles and transport vehicles, there is a great deal of focus on the development of artificial intelligence (AI), machine learning and rapid automated decision-making. While the AI and decision-making systems must plan the vehicle trajectory and response to the environment, the sensors must feed the control systems executing those algorithms with accurate data on the current and developing state of the vehicle’s surroundings.

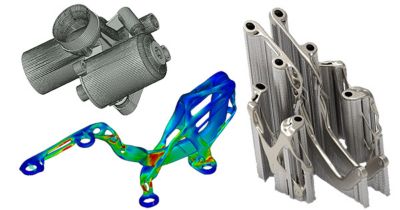

For additive manufacturing (AM) to become adopted as a mainstream industrial production technique there remains a challenge: speed + reliability. How can you rapidly optimize process parameters for additive manufactured parts, thus reducing time-to-market?

Artificial Intelligence has the potential to shift the landscape of most industries. The automation potential of AI alone can rapidly accelerate the pace of design cycles and innovation. Although introducing AI will come with its hurdles, those that start their innovation journey now will be able to lead their fields for decades to come. Download this summary to learn more.

Two incredibly big plays in autonomy are behavior prediction and 3D object detection. Both involve sensors and perception software. These features aim to reduce accidents by detecting pedestrian behavior around a moving vehicle and in-vehicle driver fatigue or negligence. To successfully implement these features, advanced recognition technologies enhanced by artificial intelligence (AI) are almost a necessity.

A new level of insight into additive manufacturing (AM) data enables engineers to control the AM process and optimize material and part performance. Results can be achieved with a greatly reduced number of experimental test cycles.

Machine learning as a service (MLaaS) is helping to support the widespread adoption and application of ML. By capitalizing on a SaaS (software-as-a-service) delivery model tuned for ML workloads, organizations can quickly join the machine learning revolution.